Hypersonic aircraft dredging-type rudderpost heat protection structure

A hypersonic and aircraft technology, applied in aircraft parts, aircraft control, ground devices, etc., can solve the problems of high manufacturing process requirements, composite material oxidation, and complicated rudder structure, and achieve good manufacturability and increase capillary force , Improving the effect of working medium backflow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with accompanying drawings and examples.

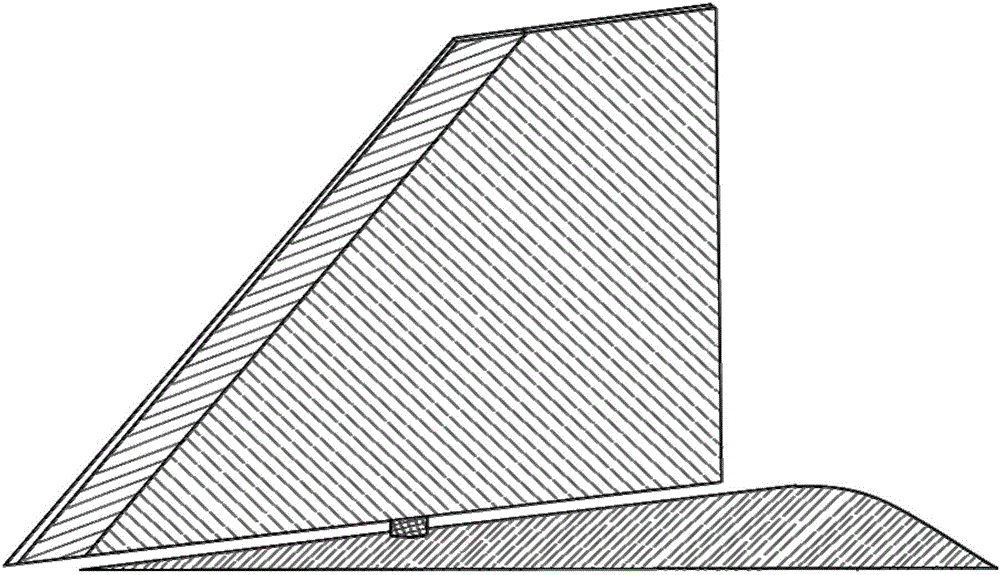

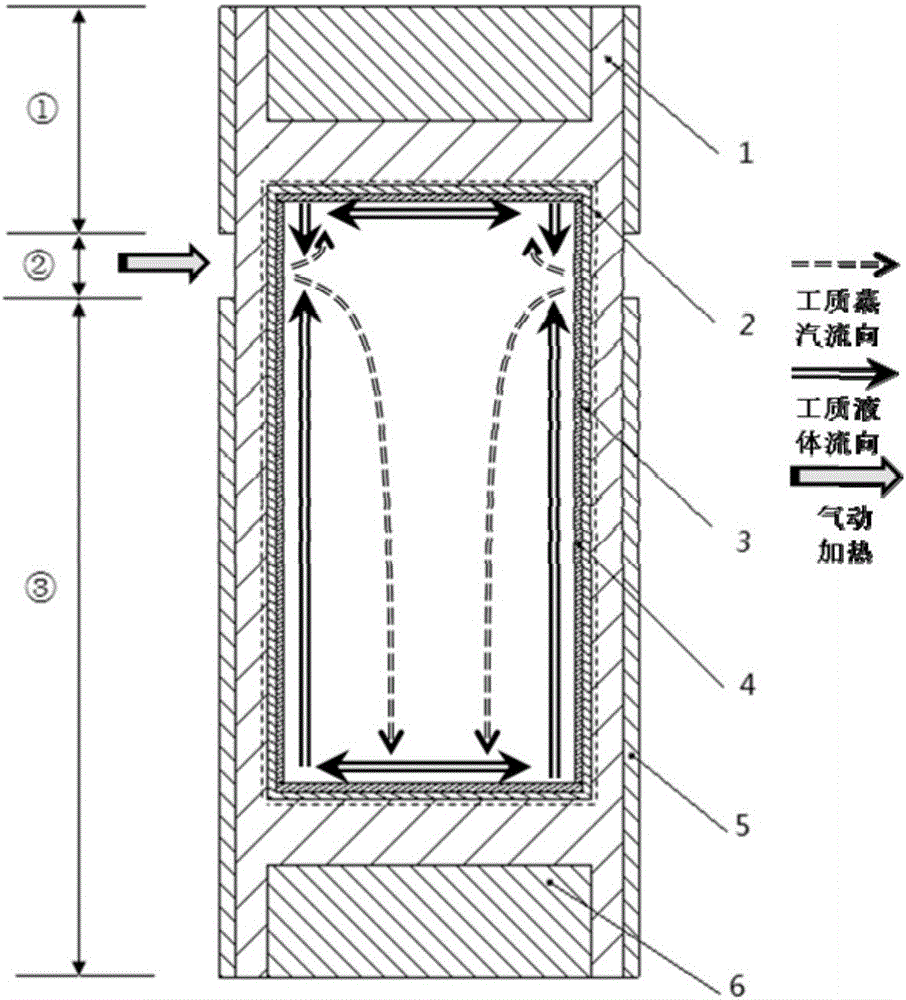

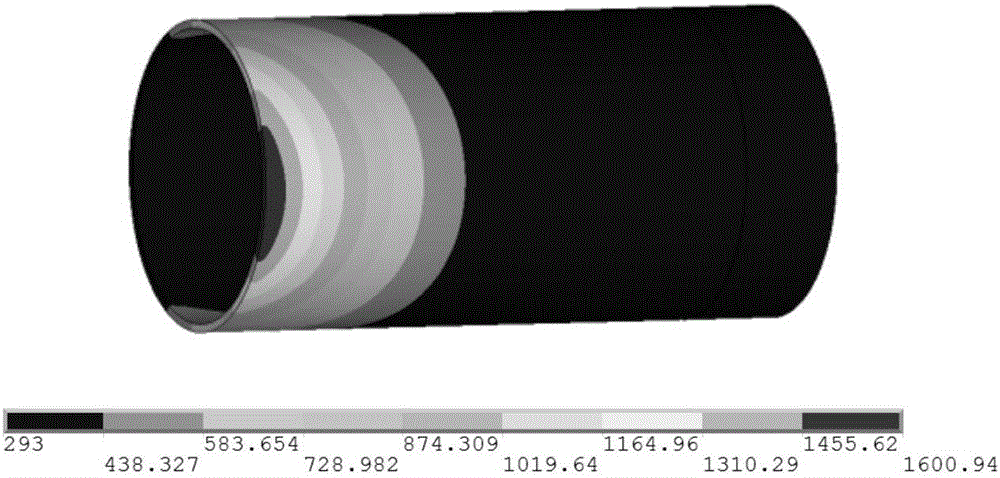

[0034] figure 1 The dredging type rudder shaft provided by the present invention is used for the connection between the rudder surface and the body. The dredging type rudder shaft provided by the present invention is a cavity-type hollow rudder shaft made of nickel-based superalloy. The shaft wall ① of the rudder surface, the rudder wall ② in the gap between the rudder surface and the steering gear, and the shaft wall ③ inside the body constitute a high-temperature heat pipe. The closed shell 1 is made of a nickel-based superalloy material with good high-temperature performance and compatibility with alkali metal working fluid; the inner surface is processed with micro-grooves 2 and capillary core 3 is laid to realize the capillary effect, which is used for the reflux of working fluid; the shell The body is filled with alkali metal sodium 4 as a heat-discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com