Sectional material forming device

A forming device and a profile technology, applied in the field of profile forming, can solve the problems of complex structure of the forming mechanism, high equipment cost, low preparation efficiency, etc., and achieve the effect of no welding equipment, no welding slag and arc, and improved preparation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings, wherein:

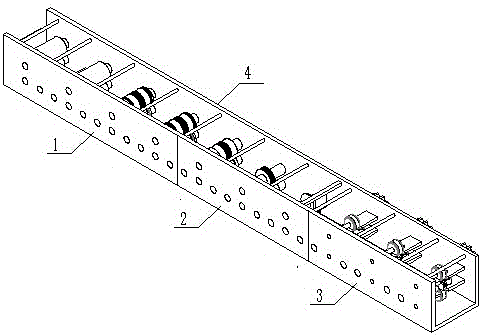

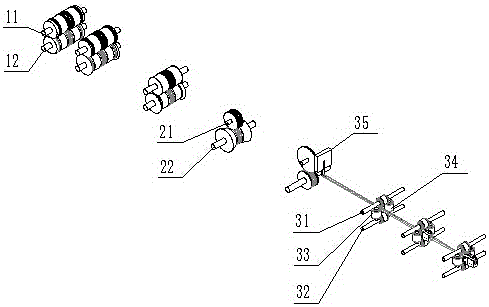

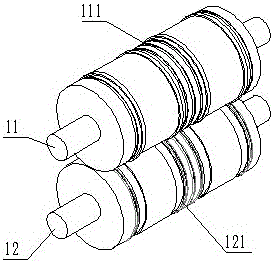

[0032] Such as Figure 1~9 Among them, a profile forming device, which includes an indentation section 1, a gathering section 2 and a forming section 3 fixed on the frame 4 in sequence, and the indentation section 1 is composed of an upper indentation roller 11 and a lower indentation roller 12 Composition, gathering section 2 is composed of gathering upper roller 21 and gathering lower roller 22, forming section 3 is composed of forming upper roller 31, forming lower roller 32, forming left roller 33, forming right roller 34 and pressing device 35, steel belt 5 It is located between the upper and lower rolls of the creasing section 1, gathering section 2 and forming section 3. The structure is simple, no welding equipment is needed, and the cost is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com