Drinking type flavored fermented milk containing granules and preparation method of drinking type flavored fermented milk

A fermented milk, drinking-type technology, applied in dairy products, applications, milk preparations and other directions, can solve the problems of loss of product characteristic flavor, uninspected influence, etc., and achieve good suspension stability, good stability, and obvious characteristic flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

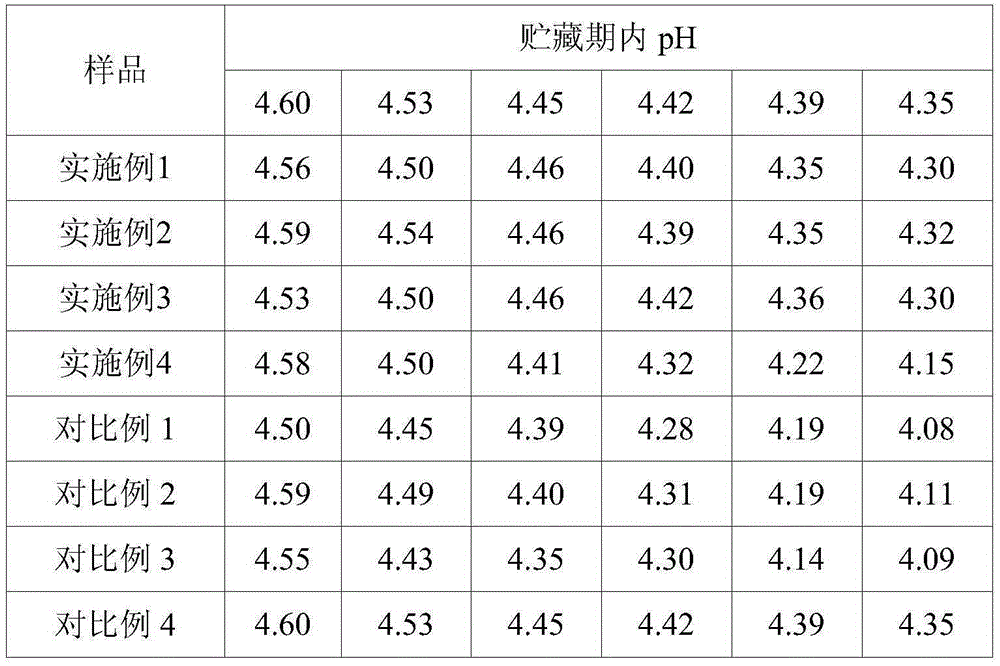

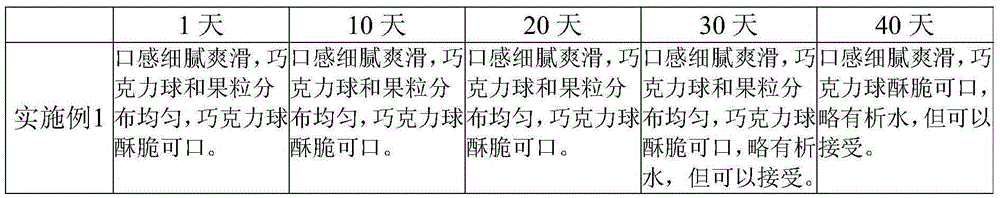

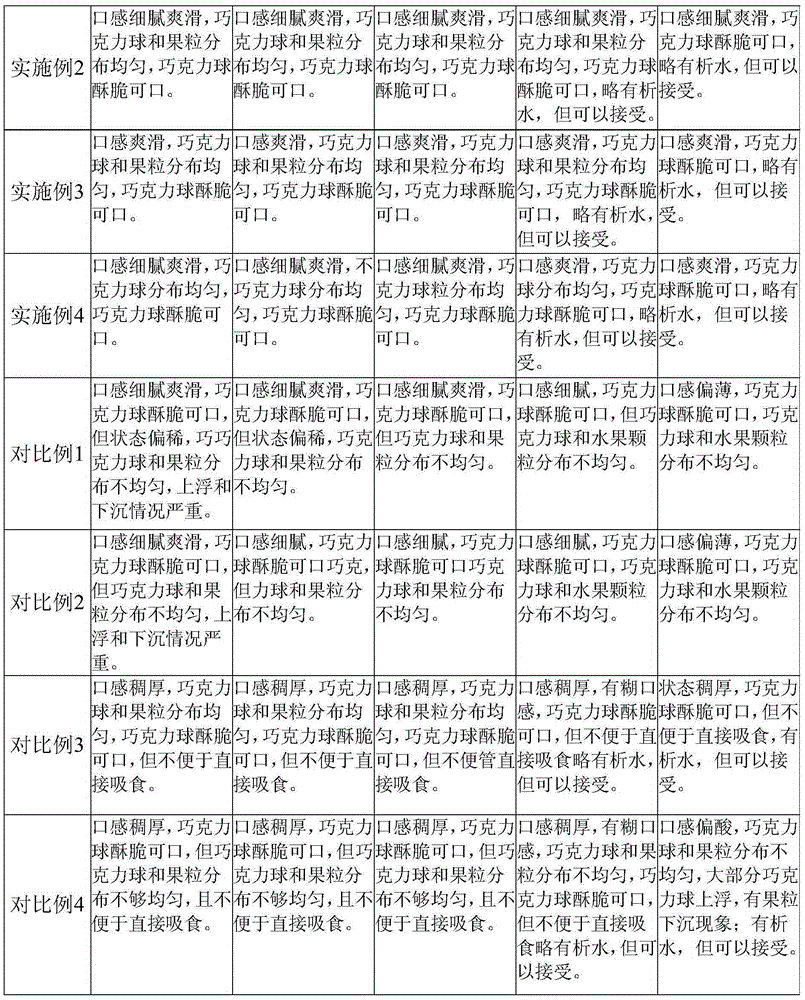

Examples

Embodiment 1

[0035] Flavored fermented milk formula (based on 1000 kg):

[0036] Egg yolk liquid 10kg;

[0037] White granulated sugar 50kg;

[0038] Appropriate amount of starter (CHR HANSEN freeze-dried strain ABT-10, including Streptococcus thermophilus, Lactobacillus bulgaricus, Bifidobacterium and Lactobacillus acidophilus, etc.);

[0039] Fruit chocolate ball mixed particle jam (the core of the chocolate ball is puffed grain particles, the outer layer is wrapped with dark chocolate coating, the particle size is 4-10mm, and the average density is about 0.8g / cm 3 ;The fruit particles are blueberry fruit particles, the particle size is 4-10mm, and the average density is about 1.24g / cm 3 )100kg;

[0040] Milk balance.

[0041] production method:

[0042] 1) Ingredients: add egg yolk liquid to milk, add white sugar, and circulate at 55-60°C for 20-30 minutes with high-speed shearing and mixing, and control the shearing speed at 1200rpm to obtain ingredient milk;

[0043] 2) Homogeni...

Embodiment 2

[0051] Flavored fermented milk formula (based on 1000 kg):

[0052] Egg yolk liquid 5kg;

[0053] Sweetener 0.5kg;

[0054] Appropriate amount of starter (CHR HANSEN freeze-dried strain ABT-10, including Streptococcus thermophilus, Lactobacillus bulgaricus, Bifidobacterium and Lactobacillus acidophilus, etc.);

[0055] Fruit chocolate ball mixed particle jam (the core of the chocolate ball is puffed grain particles, the outer layer is wrapped with dark chocolate coating, the particle size is 4-10mm, and the average density is about 0.8g / cm 3 ;The fruit particles are blueberry fruit particles, the particle size is 4-6mm, and the average density is about 1.24g / cm 3 )100kg;

[0056] Milk balance.

[0057] Except that the formula is different, the production method is basically the same as in Example 1. The prepared refined fermented milk has a viscosity of about 4150C.P. and a density of about 1.16g / mL.

[0058] After testing, the total number of viable bacteria in the prod...

Embodiment 3

[0060] The formula of flavored fermented milk is the same as in Example 1. In the production method, the filter pore size in the refinement step is 300 μm; the rest is the same as in Example 1. The prepared refined fermented milk has a viscosity of about 4400C.P. and a density of about 1.15g / mL.

[0061] After testing, the total number of viable bacteria in the product of this embodiment can reach 1 × 10 7 CFU / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com