Yoghurt maintaining viable number of probiotics in shelf life and preparation method thereof

A technology for the number of viable bacteria and shelf life, applied in milk preparations, dairy products, applications, etc., to achieve the effect of reducing the amount of addition, benefiting the health of the body, and reducing the amount of sucrose addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

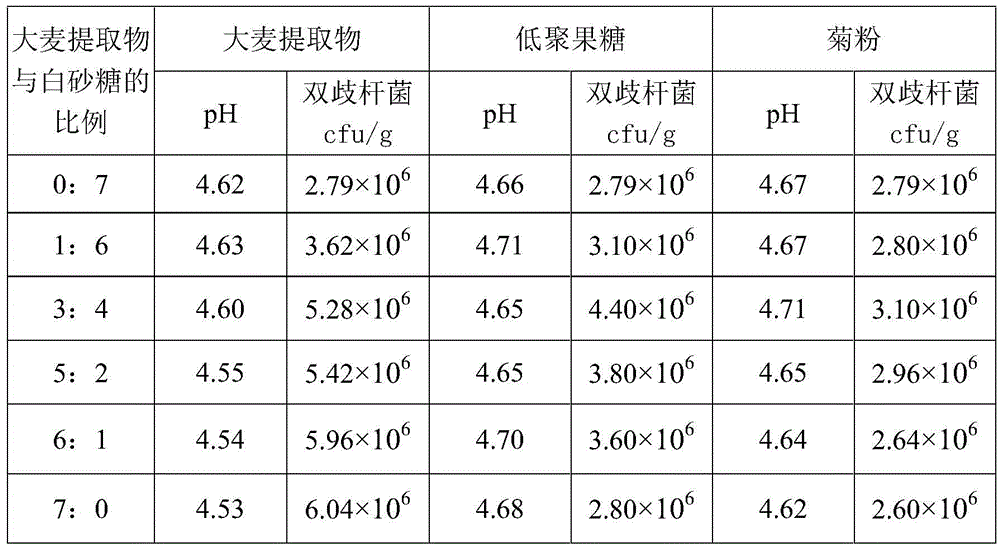

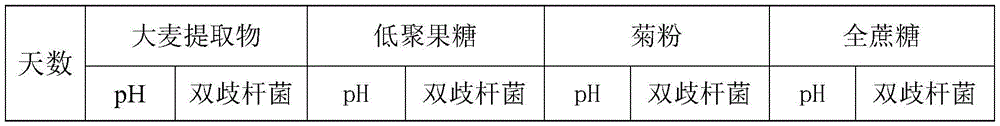

Method used

Image

Examples

Embodiment 1

[0035] A yogurt that maintains a viable count during shelf life:

[0036] The raw material composition of this yoghurt comprises (by 1000Kg): milk: 930g, white granulated sugar: 30g, barley extract: 40g, bifidobacterium lactis: 1.0×10 6 cfu / g, Lactobacillus bulgaricus: 1.0×10 7 cfu / g, Streptococcus thermophilus: 1.0×10 7 cfu / g.

[0037] The making method of this yogurt comprises the following steps:

[0038] Step 1: Put barley extract and white granulated sugar into milk to make ingredients according to parts by weight. The temperature of the ingredients is 50°C-60°C, and after 20-30min of circulation, the ingredient milk is obtained;

[0039] Step 2: Homogenize the ingredient milk, the homogenization temperature is 60°C, the secondary pressure is 40bar, and the primary pressure is 180bar;

[0040] Step 3: Sterilize the homogenized ingredient milk at 95°C±5°C for 300s;

[0041] Step 4: Cool the sterilized ingredient milk to 42°C, add Bifidobacterium lactis, Streptococcus ...

Embodiment 2

[0044] A yogurt that maintains a viable count during shelf life:

[0045]The raw material composition of the yogurt includes (in 1000g): milk: 930g, white sugar: 40g, barley extract: 30g, Lactobacillus acidophilus: 1.0×10 8 cfu / g, Lactobacillus bulgaricus: 2.0×10 7 cfu / g, Streptococcus thermophilus: 1.0×10 7 cfu / g.

[0046] The making method of this yogurt comprises the following steps:

[0047] Step 1: Put barley extract and white granulated sugar into milk to make ingredients according to parts by weight. The temperature of the ingredients is 50°C-60°C, and after 20-30min of circulation, the ingredient milk is obtained;

[0048] Step 2: Homogenize the ingredient milk, the homogenization temperature is 60°C, the secondary pressure is 40bar, and the primary pressure is 180bar;

[0049] Step 3: Sterilize the homogenized ingredient milk at 95°C±5°C for 300s;

[0050] Step 4: Cool down the sterilized ingredient milk to 42°C, add Lactobacillus acidophilus, Streptococcus therm...

Embodiment 3

[0053] A yogurt that maintains a viable count during shelf life:

[0054] The raw material composition of this yogurt includes (in 1000g): milk: 930g, white granulated sugar: 50g, barley extract: 20g, bifidobacterium lactis: 1.2×10 6 cfu / g, Lactobacillus acidophilus: 1.5×10 8 cfu / g, Lactobacillus bulgaricus: 1.0×10 7 cfu / g, Streptococcus thermophilus: 1.0×10 7 cfu / g.

[0055] The making method of this yogurt comprises the following steps:

[0056] Step 1: Put barley extract and white granulated sugar into milk to make ingredients according to parts by weight. The temperature of the ingredients is 50°C-60°C, and after 20-30min of circulation, the ingredient milk is obtained;

[0057] Step 2: Homogenize the ingredient milk, the homogenization temperature is 60°C, the secondary pressure is 40bar, and the primary pressure is 180bar;

[0058] Step 3: Sterilize the homogenized ingredient milk at 95°C±5°C for 300s;

[0059] Step 4: Cool the sterilized ingredient milk to 42°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com