High-speed steel annealing pipe

A technology for annealing tubes and high-speed steel, which is applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., and can solve the problems of inconvenient sealing of tubes and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

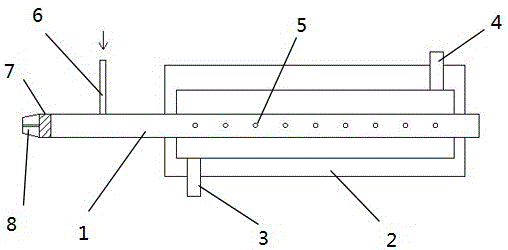

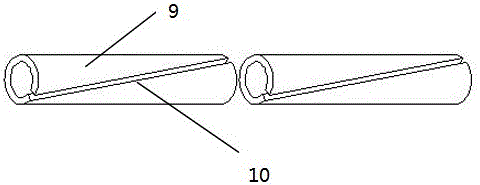

[0019] Embodiment 1: A high-speed steel annealing pipe, the high-speed steel annealing pipe includes an annealing pipe main body; a section on the annealing pipe main body is arranged in the combustion chamber; the annealing pipe main body is arranged on the pipe section in the combustion chamber and is located in the horizontal direction The two sides of the combustion chamber are provided with a plurality of gas holes; the combustion chamber is provided with an igniter; the lower end surface of the combustion chamber is provided with a fresh air inlet; the upper end surface of the combustion chamber is provided with a smoke outlet; The outlet end of the high-speed steel is provided with a flexible sealing block; the main body of the annealing pipe is provided with a hydrogen inlet on the discharge side of the combustion chamber; the hydrogen inlet is connected to a hydrogen tank.

[0020] A section of the main body of the annealing tube is set in the combustion chamber, and t...

Embodiment 2

[0021] Embodiment 2: A high-speed steel annealing pipe, the high-speed steel annealing pipe includes an annealing pipe main body; a section of the annealing pipe main body is arranged in the combustion chamber; the annealing pipe main body is arranged in the horizontal direction on the pipe section in the combustion chamber The two sides of the combustion chamber are provided with a plurality of gas holes; the combustion chamber is provided with an igniter; the lower end surface of the combustion chamber is provided with a fresh air inlet; the upper end surface of the combustion chamber is provided with a smoke outlet; The outlet end of the high-speed steel is provided with a flexible sealing block; the main body of the annealing pipe is provided with a hydrogen inlet on the discharge side of the combustion chamber; the hydrogen inlet is connected to a hydrogen tank.

[0022] The diameter of the gas hole on the annealing tube main body is 2-5 millimeters. The diameter of the g...

Embodiment 3

[0023] Embodiment 3: A high-speed steel annealing pipe, the high-speed steel annealing pipe includes an annealing pipe main body; a section on the annealing pipe main body is arranged in the combustion chamber; the annealing pipe main body is arranged on the pipe section in the combustion chamber and is located in the horizontal direction The two sides of the combustion chamber are provided with a plurality of gas holes; the combustion chamber is provided with an igniter; the lower end surface of the combustion chamber is provided with a fresh air inlet; the upper end surface of the combustion chamber is provided with a smoke outlet; The outlet end of the high-speed steel is provided with a flexible sealing block; the main body of the annealing pipe is provided with a hydrogen inlet on the discharge side of the combustion chamber; the hydrogen inlet is connected to a hydrogen tank.

[0024] The aperture of the gas hole on the main body of the annealing pipe is 2-5 millimeters, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com