Urban sewage treatment method and device in normal temperature operating mode and low temperature operating mode

An operation mode and urban sewage technology, applied in the field of water treatment, can solve problems affecting the application of high-concentration activated sludge method, and achieve the effect of improving the quality of effluent water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

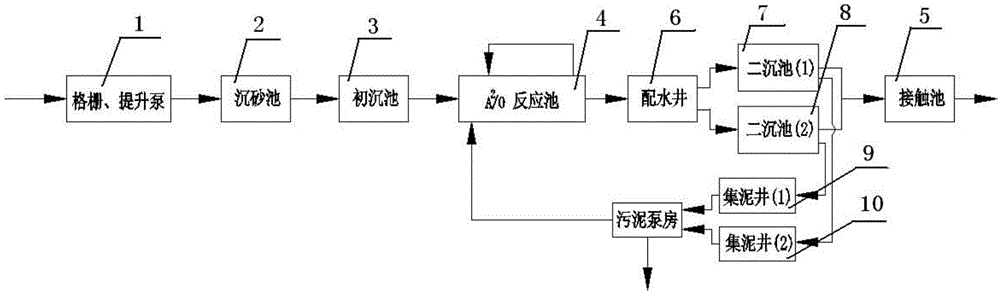

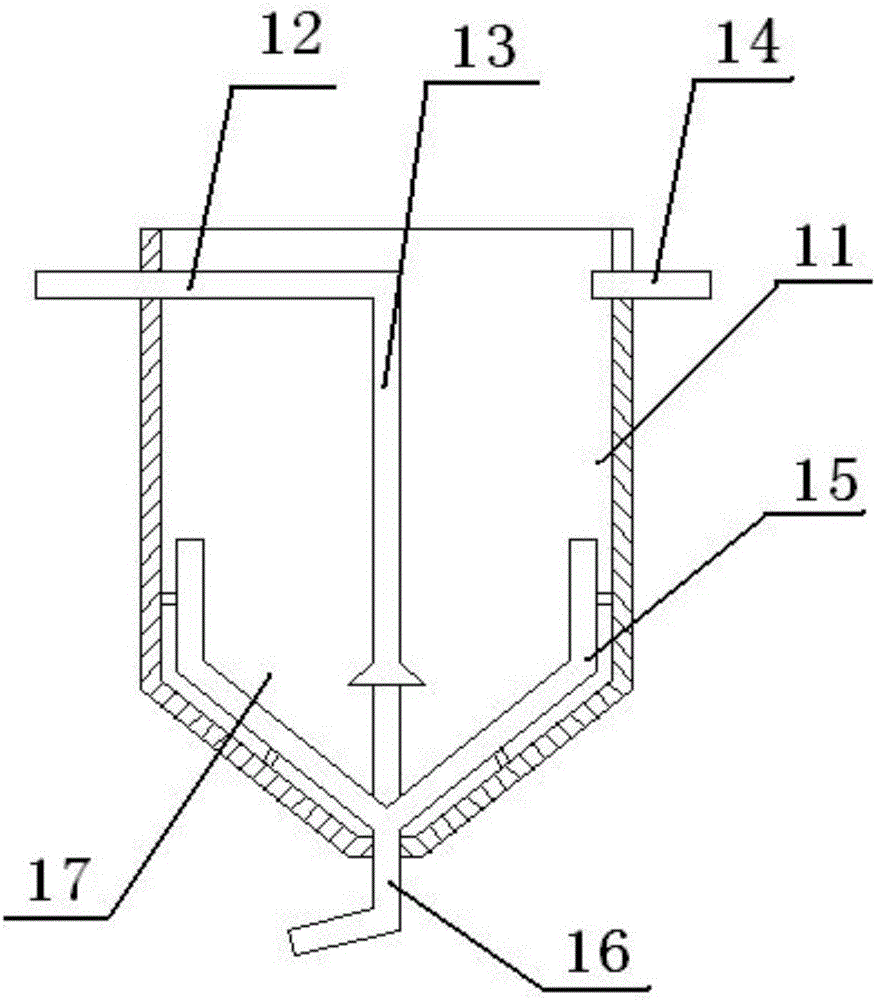

[0019] The device of the present invention consists of a grid 1, a grit chamber 2, a primary sedimentation tank 3, a three-stage pool 4, a secondary sedimentation tank, a contact pool 5, and a mud collection well to form a treatment device for urban sewage in two operating modes: normal and low temperature. The water outlet of pool 4 is connected with water distribution well 6, there are two secondary settling tanks, which are divided into left secondary settling tank 7 and right secondary settling tank 8, and there are two mud collecting wells, divided into left mud collecting well 9 and right mud collecting well Well 10 and water distribution well 6 are respectively connected to the left secondary settling tank 7 and the right secondary settling tank 8 through the converter, the left secondary settling tank 7 is connected to the left mud collecting well 9, the right secondary settling tank 8 is connected to the right mud collecting well 10, and the left secondary settling tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com