Automatic walnut picking machine

An automatic picking and walnut technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of high work intensity, safety accidents, and limited hitting force, so as to reduce labor intensity, ensure continuity, The effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

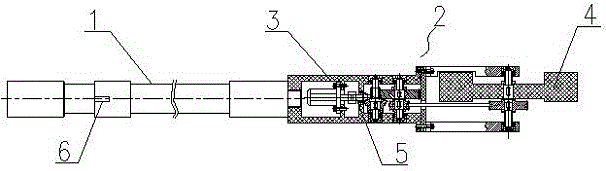

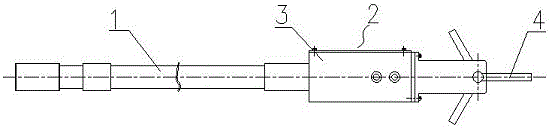

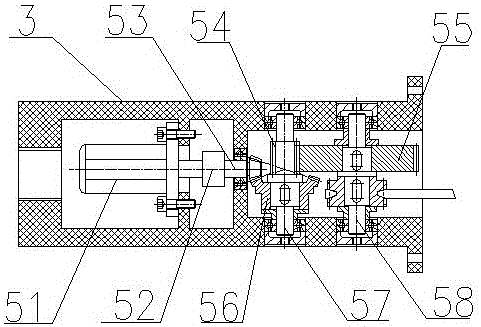

[0031] like figure 1 and figure 2 As shown, the automatic walnut picking machine includes a support rod 1, a harvesting head 2 and a hitting body 4; the harvesting head 2 is provided with a power module 5, and the power module 5 includes a drive motor 51 and a deceleration drive devices such as image 3 As shown, the deceleration transmission device includes a small bevel gear 53, a second rotating shaft 57 and a third rotating shaft 58; the second rotating shaft 57 is provided with a large bevel gear 56 and a small gear 54, and the third rotating shaft 58 is provided with a large gear 55; the small bevel gear 53 and the drive motor 51 are connected through the coupling 52, the small bevel gear 53 and the large bevel gear 56 are meshed, and the small bevel gear 54 and the large gear 55 Meshing; the belt transmission between the third rotating shaft 58 and the first rotating shaft 23 . The driving motor 51 can drive the striking body 4 to rotate so as to realize automatic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com