Fuel additive for internal combustion engine and fuel composition

A technology of additives and compositions, which is applied in the direction of fuel additives, fuels, liquid carbon-containing fuels, etc., can solve the problems of poor solubility of sediments, etc., and achieve excellent sludge removal performance, great energy-saving effects, and friction-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087]

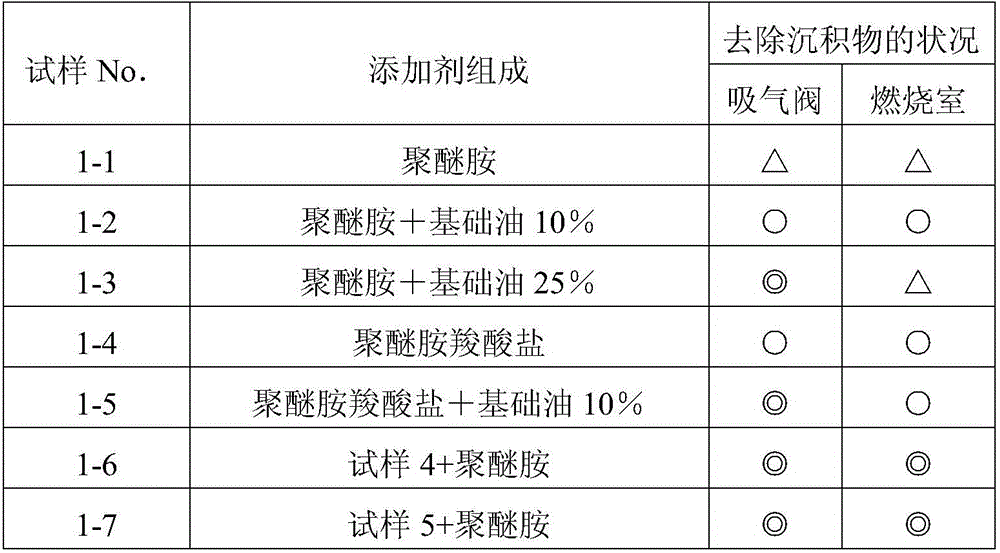

[0088] Polyetheramine, the fatty acid salt of oleic acid containing more than 50% of the polyetheramine as a polyetheramine carboxylate, and the polyetheramine are each added with 10% and 25% of nonylphenol as a base oil. The additive after the oxybutane polymer and the additive after adding 10% of the above polymer to the polyetheramine carboxylate were added to commercially available standard gasoline in equal amounts so as to become 2500 ppm based on the polyetheramine. The performance of removing deposits inside the intake valve and the combustion chamber was confirmed, and the results are shown in Table 1. Furthermore, two types of additives in which 500 ppm of polyetheramine was added in an equal amount were prepared as samples.

[0089] Detergency Test 1

[0090]

[0091] General example ◎: excellent, ○ good, △ not good

[0092] In the above evaluation, 3% engine oil was added to gasoline in advance, Subaru Generator SGi25S was operated for 50 hours to ...

Embodiment 2

[0094]

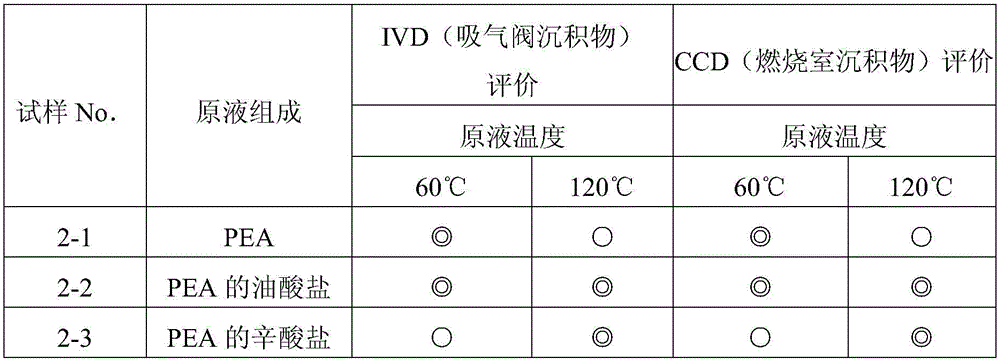

[0095] Immerse the sediment of the suction valve in the stock solution of polyetheramine, polyetheramine oleate and polyetheramine caprylate at different temperatures to judge their dissolution status.

[0096] The polyetheramines and their salts used in the evaluation ([R 2 -O(AO)m-XH + ]), using the most balanced value R 2 =13, A=4 (alkylene group having 4 carbons), m=20, and X is a polyetheramine of the group when n=1.

[0097] Detergency test 2

[0098]

[0099] General example ◎: excellent, ○ good

Embodiment 3

[0101]

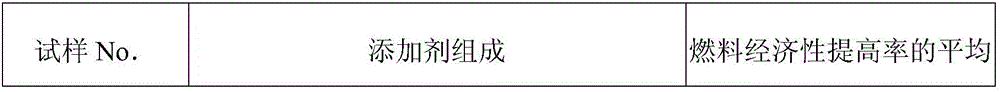

[0102] Polyetheramine, polyetheramine carboxylate (crude oleic acid, a mixture of fatty acids containing oleic acid as a carboxylic acid), fatty acid (crude oleic acid, a mixture of fatty acids containing the same oleic acid as the carboxylate) , polyetheramine cyclohexane salt, etc., and polyetheramine 1000ppm (concentration in standard gasoline) equivalent acid and salt, using a number of different engines to measure the actual fuel economy. Polyetheramine uses the R 2 =13, A=4 (alkylene group having 4 carbons), m=20, and X is a polyetheramine of the group when n=1.

[0103] Fuel economy comparison of polyetheramine carboxylates

[0104]

[0105]

[0106] The values in Table 3 are the average values of highway bodies obtained with 150cc single-cylinder engine, 250cc four-cylinder engine, 1300cc four-cylinder engine, 1300cc direct injection engine, and 2000cc four-cylinder turbocharged engine.

[0107] For each vehicle, the deposits inside the engine w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com