Induction motor provided with cast copper rotor

A technology for induction motors and rotors, applied in the direction of asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of low power density and low efficiency, and achieve the effects of low additional loss, reduced copper loss, and good starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

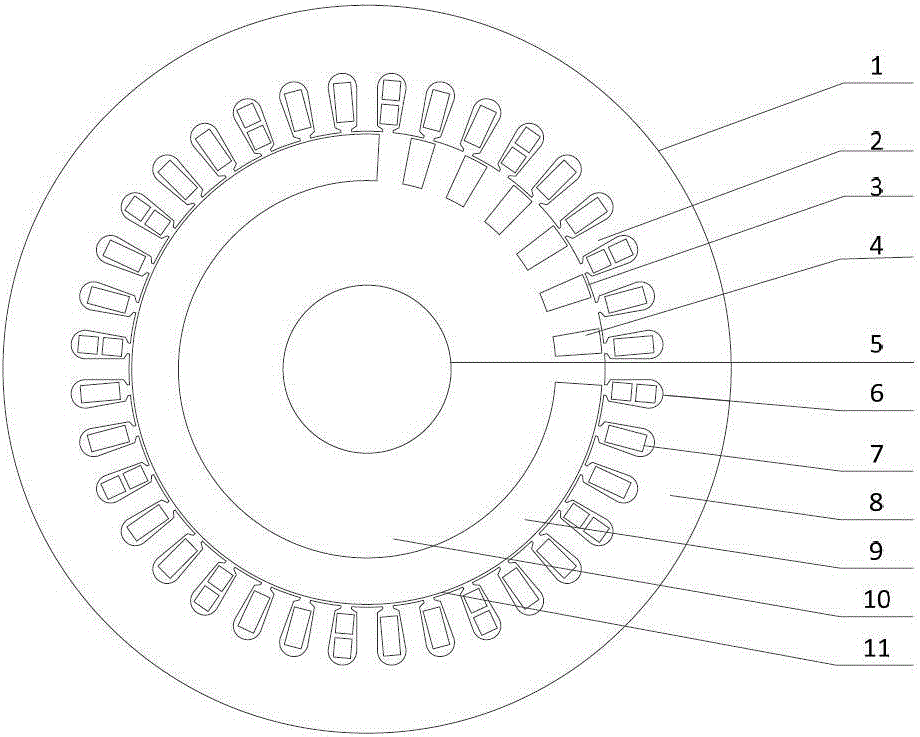

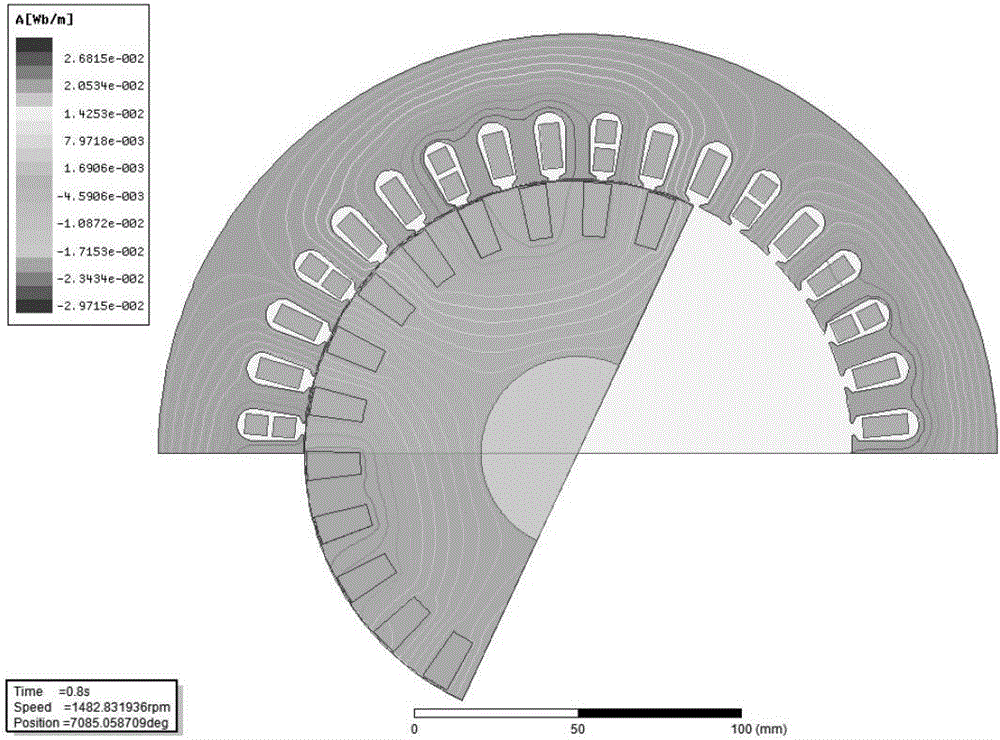

[0020] Such as figure 1 , 2 As shown, a cast copper rotor induction motor includes a stator 1, a rotor 11 and a rotating shaft 5, the rotor 11 is located in the stator 1, and there is an air gap 3 between the stator 1 and the rotor 11, and the stator 1 includes stator teeth 2. Stator slots 6, armature windings 7 and stator yoke 8, the rotor 11 includes a rotor core 10, guide bars 4 and end rings 9;

[0021] The winding type adopted by the armature winding 7 is a single-layer winding, and the upper and lower conductors of the same phase in the short-distance winding are combined to use a single-layer winding, while the upper and lower conductors of different phases adopt a double-layer winding, and are arranged according to the concentric The end shape of the double-layer winding is used to connect the ends to form a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com