Unequal turn single-double-winding cast copper rotor induction motor

An induction motor, single-layer technology, applied to asynchronous induction motors, winding conductive materials, and the shape/style/structure of winding conductors, which can solve the problems of low power density and low efficiency, and achieve low additional loss and copper loss. Reduced, good starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0015] The invention provides an induction motor with unequal turn single-layer and double-layer winding cast copper rotors, which can save copper for stator windings, weaken 5th, 13th, 23rd or 7th, 11th harmonics, reduce motor temperature rise, and improve motor efficiency.

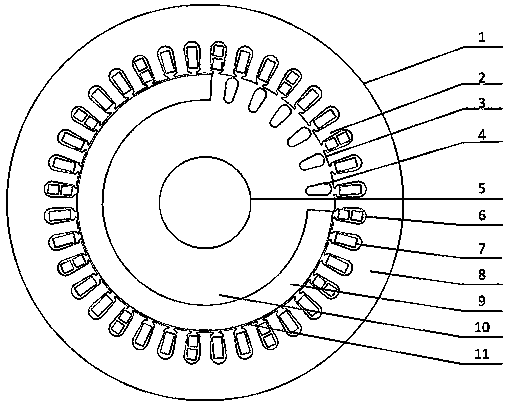

[0016] like figure 1 , 2 As shown, a cast copper rotor induction motor includes a stator 1, a rotor 11 and a rotating shaft 5, the rotor 11 is located in the stator 1, and there is an air gap 3 between the stator 1 and the rotor 11, and the stator 1 includes stator teeth 2. Stator slots 6, armature windings 7 and stator yoke 8, the rotor 11 includes a rotor core 10, guide bars 4 and end rings 9;

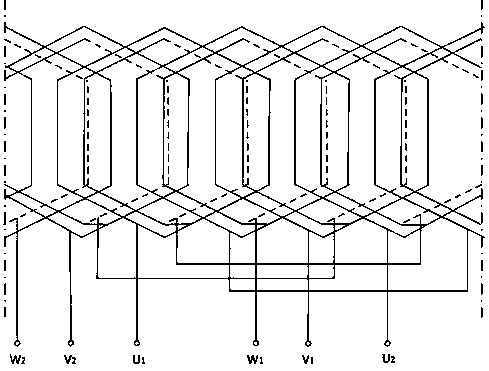

[0017] The winding type adopted by the armature winding 7 is a single-layer winding, and the upper and lower conductors of the same phase in the short-distance winding are comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com