A Differential Protection Method Suitable for Variable Frequency Motor

A variable frequency motor and differential protection technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve problems such as heat generation, motor harmonics, and equipment long-term operation effects, and achieve suppression of DC components and harmonic components, and anti-interference capabilities Strong, fast and reliable protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

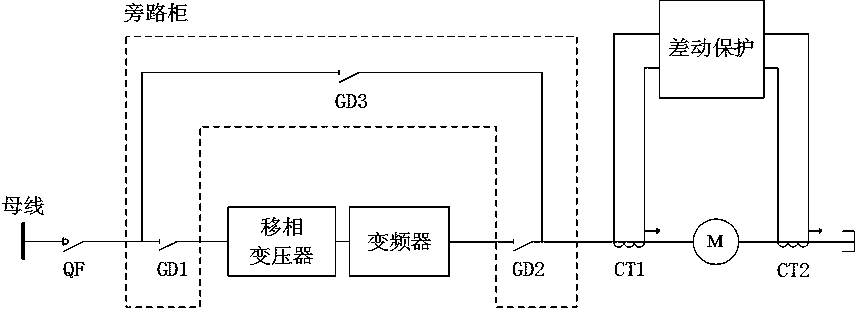

[0029] In order to ensure that the operation of the high-voltage motor will not be affected when the frequency converter fails, the frequency conversion transformation basically adopts the structure of frequency converter processing frequency bypass. figure 1 As shown, the high-voltage frequency conversion system mainly includes three parts: a phase-shifting transformer, a frequency converter, and a bypass cabinet. The phase-shifting transformer plays the role of system isolation. For the switching of frequency conversion / power frequency operation mode. When the motor is running at power frequency, the bypass switch GD3 is closed, and GD1 and GD2 are disconnected; when the motor is running at variable frequency, the bypass switch GD3 is disconnected, and GD1 and GD2 are closed. Considering the power frequency operation of the motor, the cable from the incoming line switch to the motor machine end can be protected by the original motor comprehensive protection device, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com