Semiconductor pumping solid laser device

A solid-state laser and semiconductor technology, applied in the field of lasers, can solve the problems of process cost and material cost, inconvenient installation, and the influence of laser light output power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

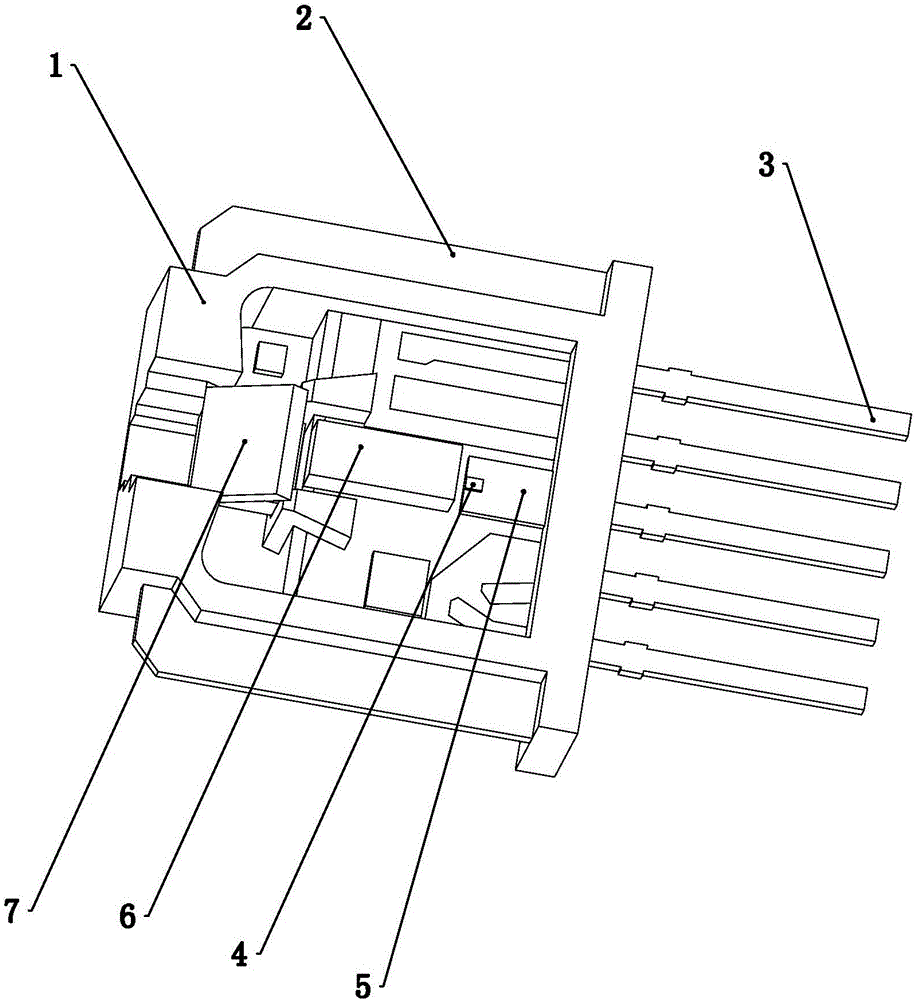

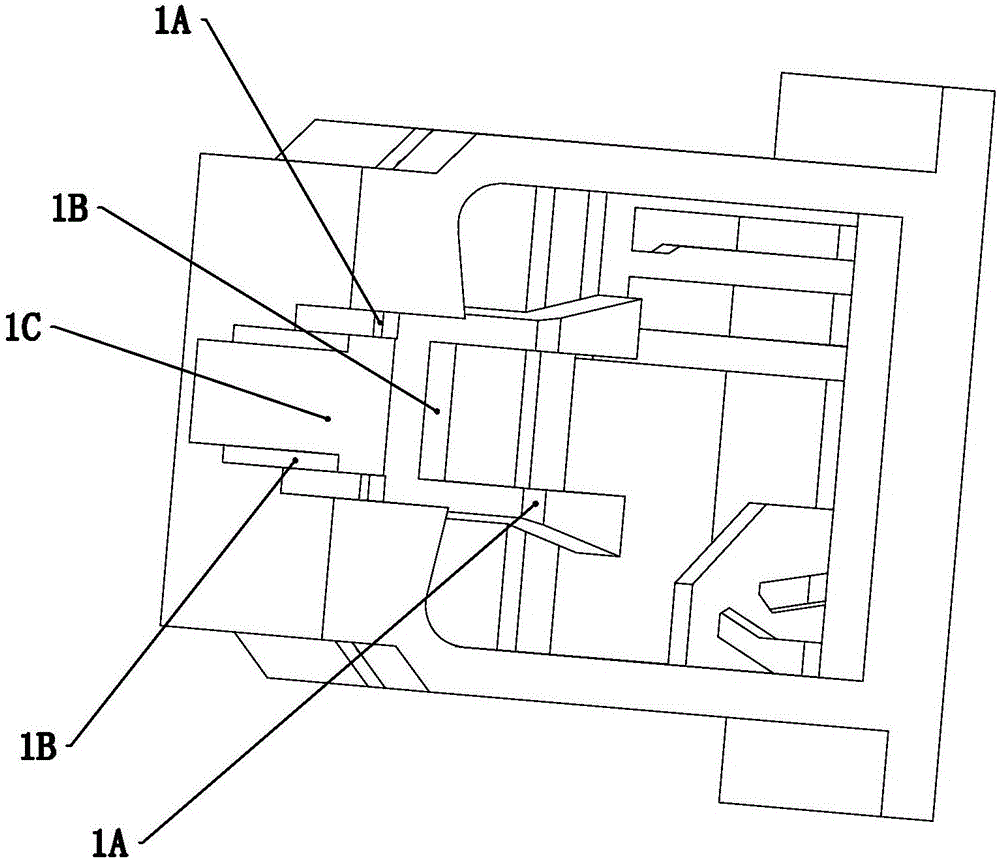

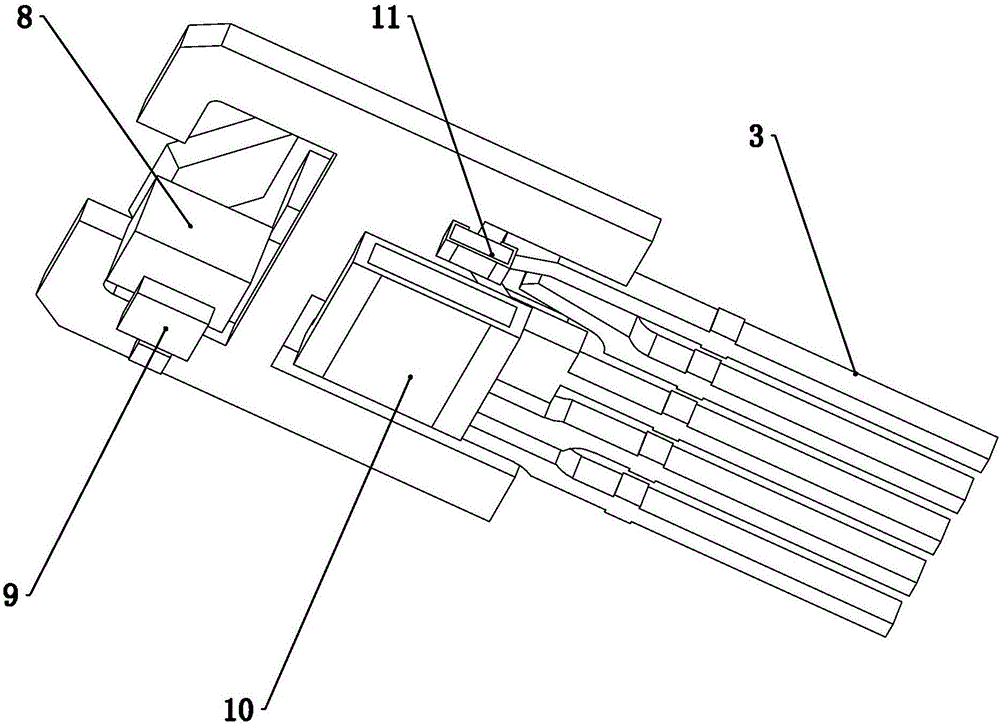

[0015] Such as figure 1 — Figure 4 As shown, a semiconductor pumped solid-state laser includes a plastic fixing frame 1, a metal bracket 2, pins 3, an LD chip 4 and a heat sink 5, wherein the plastic fixing frame 1 is fixed on the metal bracket 2 by injection molding, and the heat sink The chip 5 is fixed or integrally connected with the metal bracket 2. The LD chip 4 is inlaid with the upper surface of the heat sink 5. The inlay can be pasted or connected with silver glue. The metal bracket 2 is flat. In the embodiment, it also includes a frequency doubling crystal 6, a light splitter 7, a filter 8 and a receiving silicon photocell 9, wherein the frequency doubling crystal 6 is located directly in front of the LD chip 4, and the light splitter 7 is located in front of the frequency doubling crystal 6 , and is inclined relative to the frequency doubling crystal 6, a filter 8 and a receiving silicon photocell 9 are arranged below the beam splitter 7; by adopting the above sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com