Film coating and packaging device and method for pole piece large coil of lithium ion battery

A technology for lithium-ion batteries and battery pole pieces, which is applied in the field of film-coated packaging devices for large rolls of lithium-ion battery pole pieces. The effect of smooth and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

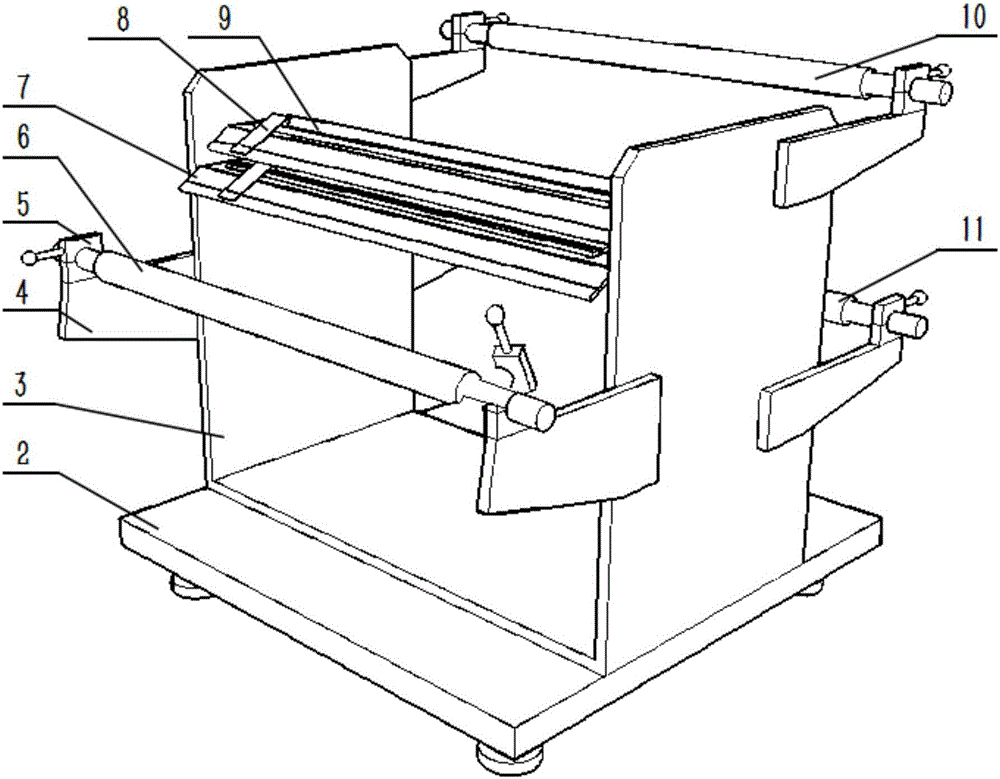

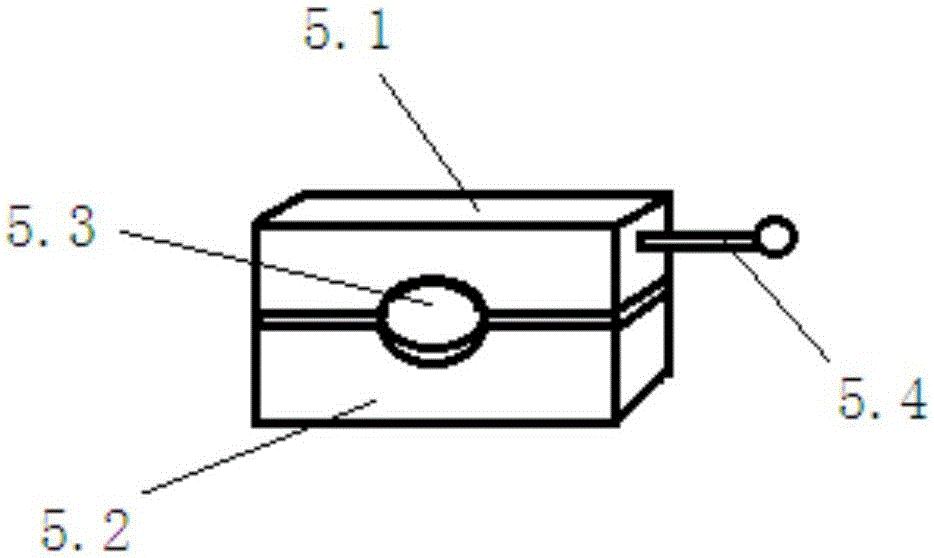

[0037] Such as figure 1 , 2 As shown, a film-coated packaging device for large rolls of lithium-ion battery pole pieces includes a U-shaped frame 3 installed on a bottom plate 2, the top of the U-shaped frame 3 is connected by a guide plate 7, and the guide plate 7 A pressing plate 9 is arranged on the top, and a knife holder 8 with a cutter 12 is connected to the pressing plate 9; the two side walls of the U-shaped frame 3 are symmetrically fixed with a large roll 15 for fixing the battery pole piece, a pearl The support 4 of the large cotton roll 13 and the large roll of plastic wrap 14, the top of the support 4 is fixed with a clamp 5 for clamping the fixed reel.

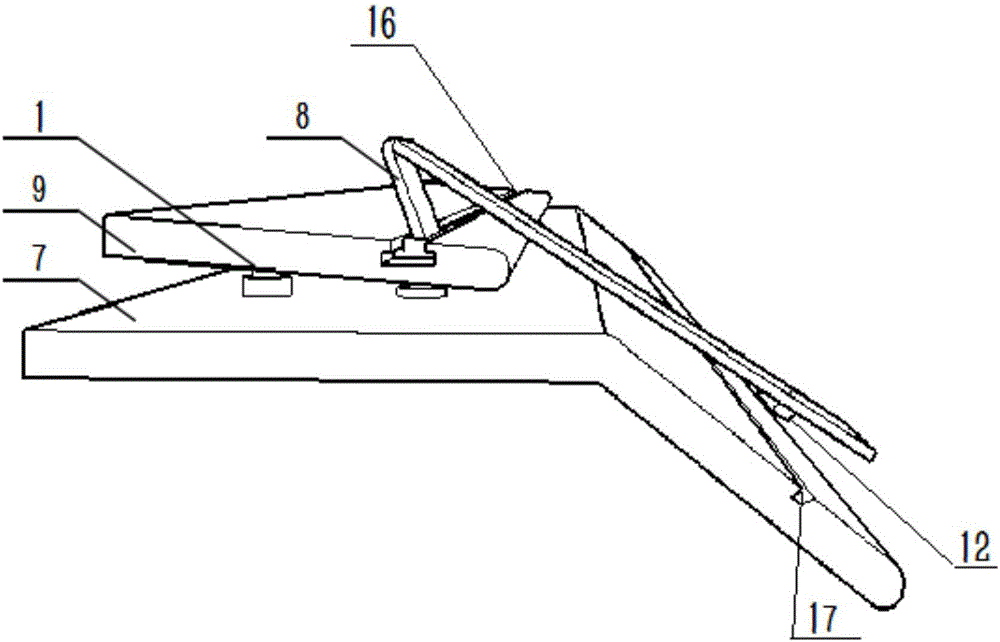

[0038] In a further solution, the guide plate 7 and the pressing plate 9 are connected through a damper 1 .

[0039] In a further solution, a guide rail 16 parallel to the reel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com