Automatic limiting and short-circuit-proof liquid supplementing and feeding system for storage battery pack

An automatic limit, battery pack technology, applied in battery pack parts, batteries, circuits, etc., can solve the problems of difficult limit and low safety in battery replenishment operation, and avoid liquid spillage and external gas and dust. The effect of intrusion, ensuring reliability, and improving product safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

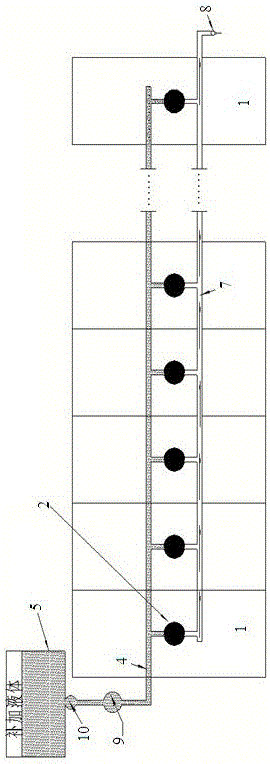

[0039] Such as figure 1As shown, an automatic position-limiting anti-short-circuit refilling system for battery packs includes a battery pack composed of a plurality of single batteries 1, and the liquid replenishment and exhaust combination cover of each single battery 1 is respectively equipped with an automatic Limiting and anti-short circuit refilling device 2, the refilling ports 3 of the automatic limit and anti-short circuit refilling device 2 are respectively connected to the refilling pipe 4, and one end of the refilling pipe 4 is connected to the centralized liquid storage tank 5 , the other end of the replenishing liquid pipe 4 is sealed, and the exhaust port 6 of the automatic limit and anti-short circuit replenishing liquid device 2 is respectively connected with the exhaust pipe 7, and one end of the exhaust pipe 7 is sealed, and the other end of the exhaust pipe 7 passes through The exhaust one-way valve 8 communicates with the outside atmosphere, and a control ...

Embodiment 2

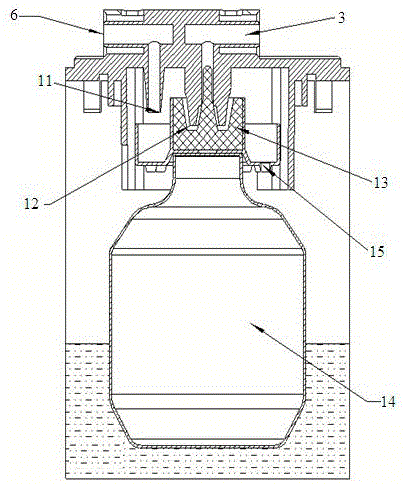

[0041] The structural diagram of the direct automatic limit and short-circuit replenishment device is as follows: figure 2 As shown, the automatic position-limiting anti-short-circuit refilling device includes a refilling port 3 and an exhaust port 6 arranged on the liquid replenishment and exhaust combination cover, wherein an outlet extending to the inside of the battery case is provided under the exhaust port 6. The air pipe 11 and the liquid inlet 3 are provided with a liquid inlet pipe 12 extending to the inside of the battery case. The liquid inlet pipe 12 is provided with a sealing nail 13 that is in sliding and sealing fit with it. The bottom of the sealing nail 13 is provided with a The end of the liquid pipe 12 matches the ring-shaped sealing groove, and the bottom end of the sealing nail 13 is fixed on the buoy 14. The sealing nail 13 is provided with a flow-distributing drip screen 15, and the flow-distributing drip screen 15 is located below the replenishing liqui...

Embodiment 3

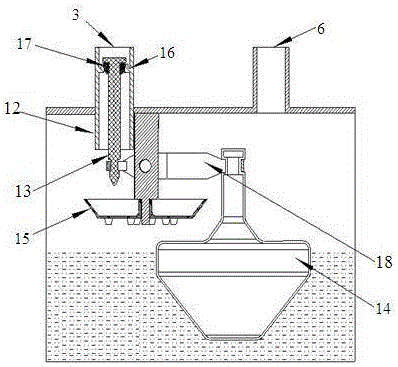

[0043] Schematic diagram of the structure of the power-increasing single-lever type automatic limit short-circuit prevention replenishing liquid device is as follows: image 3 As shown, the automatic limit and short-circuit replenishment device includes a replenishment port 3 and an exhaust port 6 arranged on the liquid replenishment and exhaust combination cover, wherein the bottom of the replenishment port 3 is provided with a The liquid inlet pipe 12 with gas storage and anti-short circuit function, the inner side of the supplementary liquid port 3 is provided with a hollow sealing bowl 16, and the hollow sealing bowl 16 is provided with a rubber sealing ring 17, and the interior of the supplementary liquid port 3 is provided with a hollow seal. The sealing nail 13 adapted to the sealing bowl 16, the bottom end of the sealing nail 13 is fixedly connected to one end of the booster lever 18, and the lower part of the replenishment and exhaust combination cover adjacent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com