A kind of preparation method of carbon nanotube/fabric flexible composite electrode material

A carbon nanotube and composite electrode technology, which is applied in the field of electrochemical energy storage material preparation, can solve the problems of easy detachment of carbon nanotubes, poor water washability of composite materials, etc., and achieves softness, washability, light weight and good softness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Hydrophilic treatment of polyester:

[0038] 3×5cm 2 The polyester is placed in 200g / L sodium hydroxide solution for 30min, and then rinsed with deionized water for use.

[0039] (2) Preparation of carbon nanotube dispersion:

[0040] 0.024 g of carboxylated carbon nanotubes and 0.024 g of sodium dodecylbenzene sulfonate (SDBS) were placed in 20 mL of deionized water for ultrasonic dispersion for 1 hour to prepare a carbon nanotube dispersion.

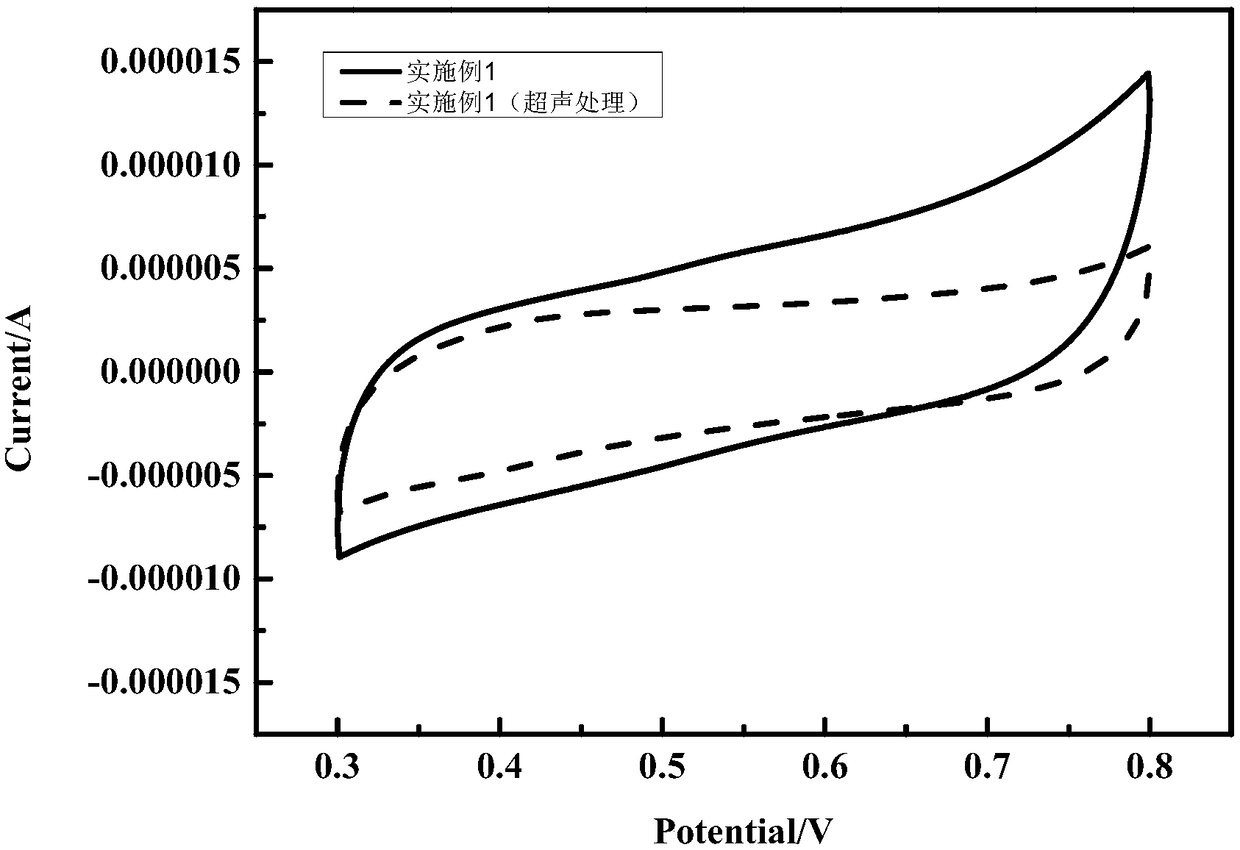

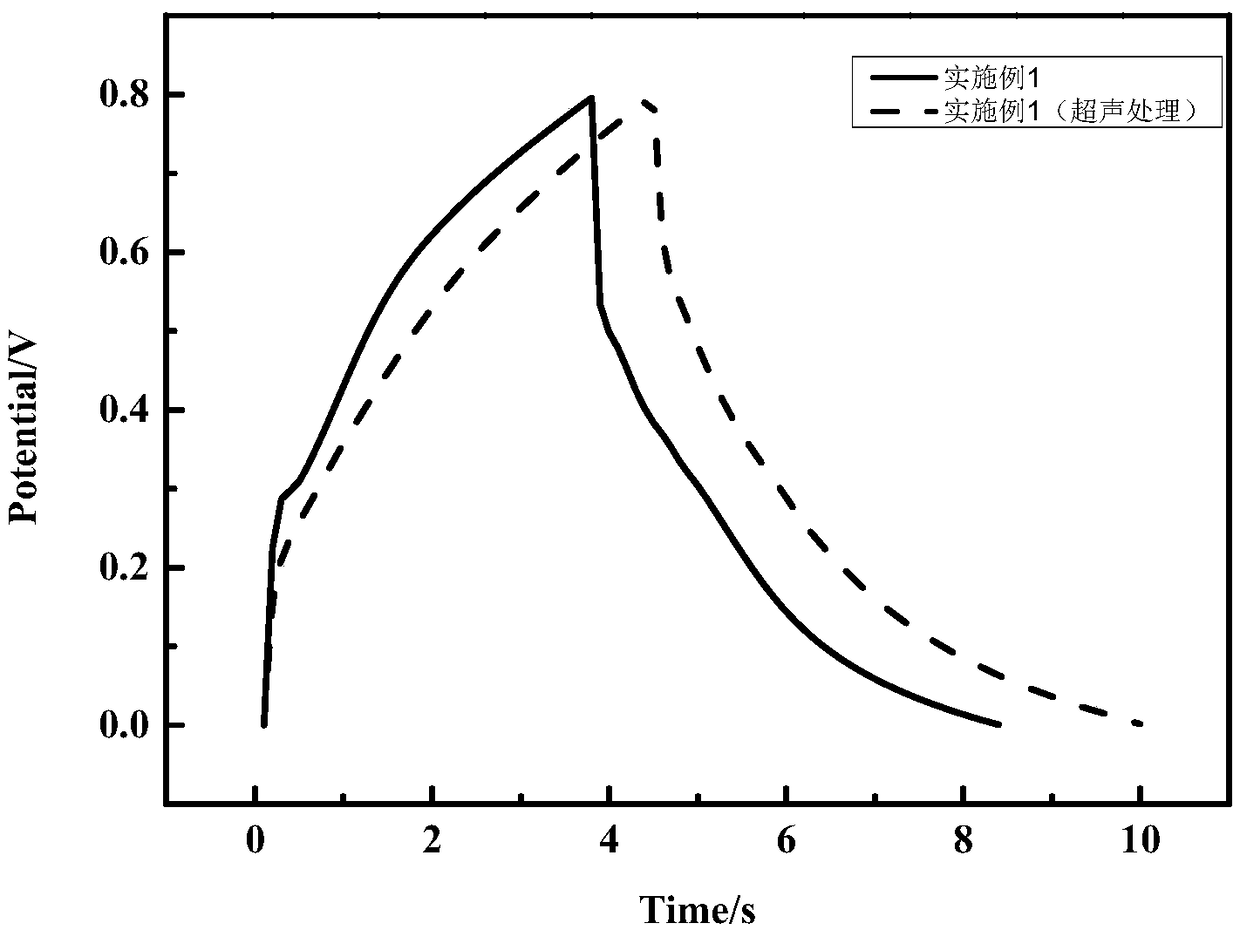

[0041] (3) Preparation of carbon nanotube / polyester flexible composite electrode:

[0042] Put the hydrophilic polyester obtained in step (1) and the carbon nanotube dispersion obtained in step (2) in an infrared dyeing machine for processing, cool to room temperature, take out, wash, and dry at room temperature; among them, hydrophilic polyester The mass ratio to the carbon nanotube dispersion is 1:50.

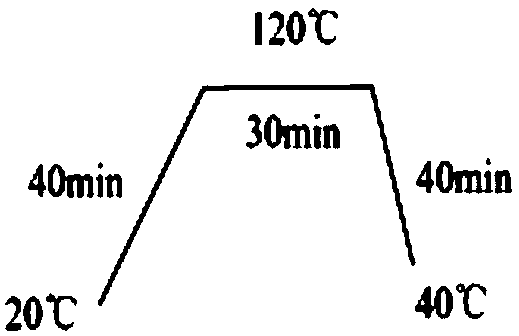

[0043] The treatment process is: heating from 20°C to 120°C at a heating rate of 2.5°C / min, then holding for 30 minutes, and then c...

Embodiment 2

[0047] (1) Hydrophilic treatment of polyester cotton:

[0048] 3×5cm 2 The polyester cotton is treated in 200g / L sodium hydroxide solution for 30min, and then rinsed with deionized water for later use.

[0049] (2) Preparation of carbon nanotube dispersion:

[0050] 0.024 g of carboxylated carbon nanotubes and 0.024 g of sodium dodecylbenzene sulfonate (SDBS) were placed in 20 mL of deionized water for ultrasonic dispersion for 1 hour to prepare a carbon nanotube dispersion.

[0051] (3) Preparation of carbon nanotube / polyester-cotton flexible composite electrode:

[0052] After mixing the hydrophilic polyester cotton obtained in step (1) with the carbon nanotube dispersion obtained in step (2), it is placed in an infrared dyeing machine for processing, cooled to room temperature, taken out and washed, and dried at room temperature to obtain Carbon nanotube / polyester-cotton flexible composite electrode material, wherein the mass ratio of polyester-cotton and carbon nanotube dispersion ...

Embodiment 3

[0057] (1) Hydrophilic treatment of polyester:

[0058] 3×5cm 2 The polyester is placed in 200g / L sodium hydroxide solution for 30min, and then rinsed with deionized water for use.

[0059] (2) Preparation of carbon nanotube dispersion:

[0060] 0.024 g of carboxylated carbon nanotubes and 0.012 g of sodium dodecylbenzene sulfonate (SDBS) were placed in 20 mL of deionized water for ultrasonic dispersion for 1 hour to prepare a carbon nanotube dispersion.

[0061] (3) Preparation of carbon nanotube / polyester flexible composite electrode:

[0062] Put the hydrophilic polyester obtained in step (1) and the carbon nanotube dispersion obtained in step (2) in an infrared dyeing machine for processing, cool to room temperature, take out, wash, and dry at room temperature; among them, hydrophilic polyester The mass ratio to the carbon nanotube dispersion is 1:50.

[0063] The treatment process is: heating from 20°C to 130°C at a heating rate of 2.5°C / min, then holding for 45 minutes, then cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com