Built-in magnetic-shield transformer body pressing plate

A magnetic shielding and transformer technology, applied in the field of transformers, can solve problems such as accelerated insulation aging, reduced service life of transformers, overheating of electromagnetic wires, etc., and achieves the effects of reducing magnetic flux leakage, avoiding lateral magnetic flux leakage, and avoiding the influence of magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

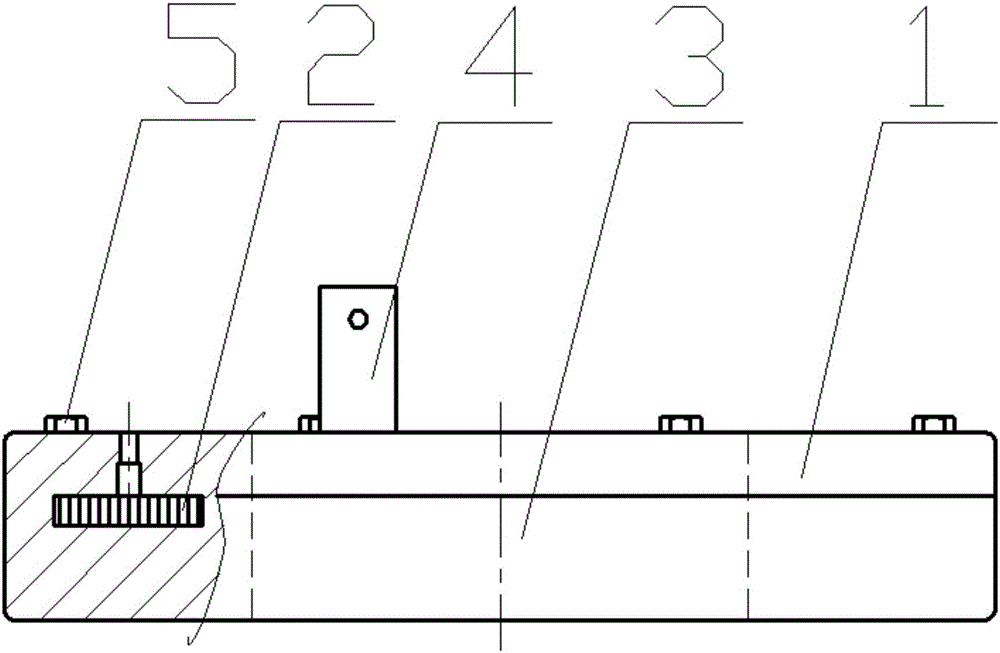

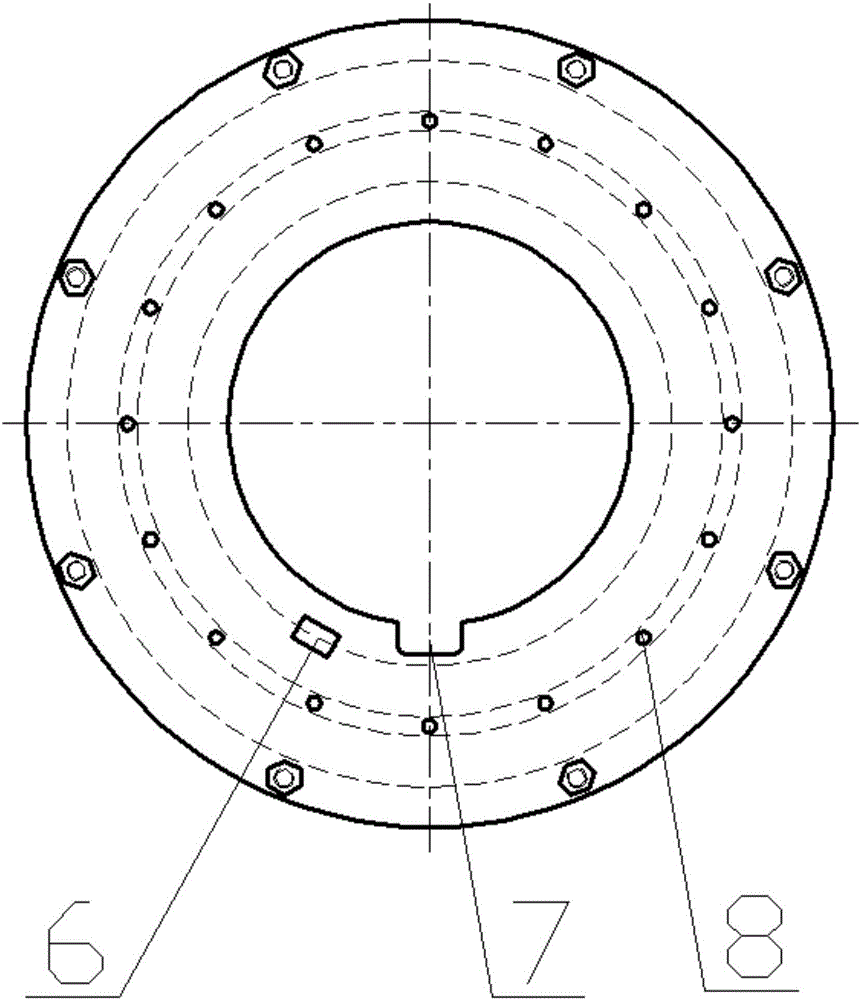

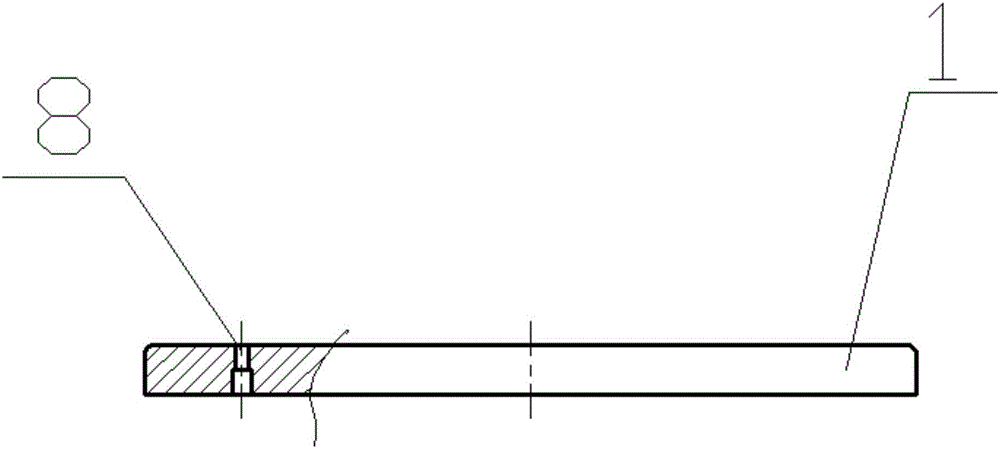

[0032] As shown in the figure, a body pressure plate of a built-in magnetic shielding transformer includes an upper pressure plate 1 , a wound magnetic shield 2 , a lower pressure plate 3 and high-strength nylon bolts 5 . The wound magnetic shield is welded with a grounding copper tape 4 . The upper pressure plate 1 and the lower pressure plate 3 are provided with a gap 7 for the outlet of the low-voltage winding.

[0033] The upper pressure plate 1 includes a grounding copper strip opening 6 , an oil guide hole 8 , an oil guide groove 9 , a low-voltage winding outlet notch 7 and a nylon bolt opening 10 . The upper pressing plate 1 is a ring structure, the inner and outer diameters are the same as the traditional structure transformer body pressing plate, the thickness is 10mm-20mm, and the material is laminated wood, laminated cardboard or hot-pressed polyester resin plastic laminate. The upper pressure plate is equipped with a grounding copper tape opening 6 for the groundi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com