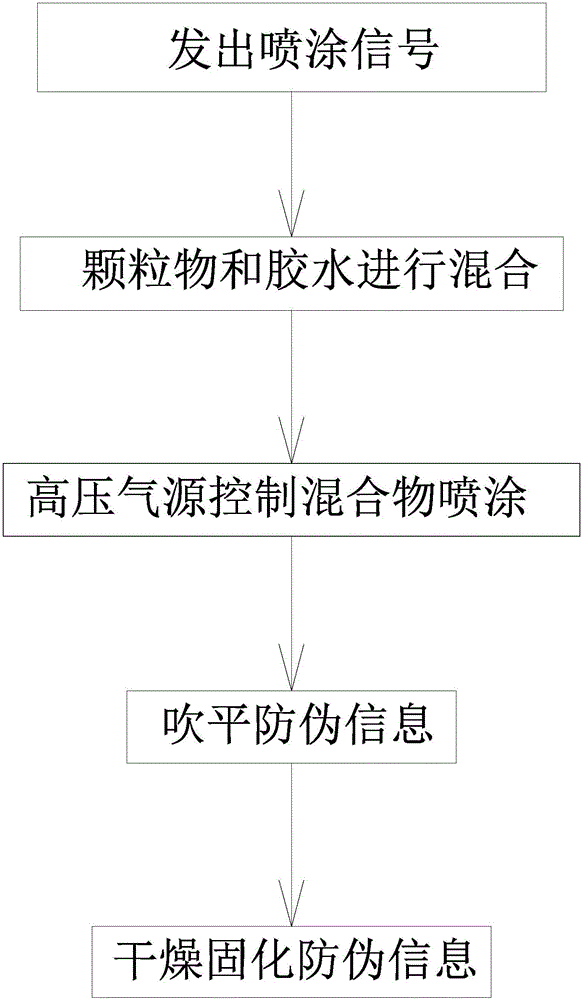

Anti-counterfeit label manufacturing method

An anti-counterfeiting label and manufacturing method technology, applied in the field of anti-counterfeiting, can solve the problems such as the inability of anti-counterfeiting information to pass, the realization of spraying methods, etc., and achieve the effects of easy control of coating thickness, product quality assurance, and reduction of production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

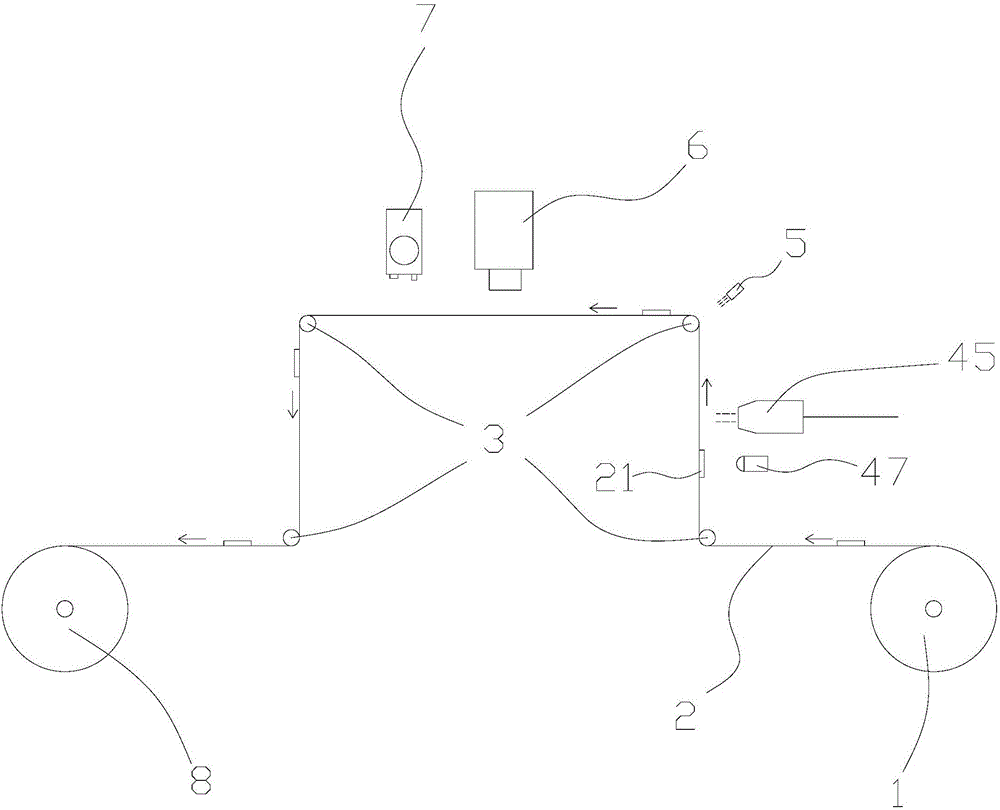

Examples

Embodiment 2

[0060] The anti-counterfeit label manufacturing equipment provided in this embodiment has roughly the same structure as that of Embodiment 1, the only difference is that in step b1 of this embodiment, the mixture of glue and particles loaded in the tank 44, the mixture of particles and glue The weight ratio is 0.3, the glue is UV-curable transparent glue, and the viscosity of the glue is controlled at 45 seconds when measured with Zion's No. 3 cup. The material of the particles is black PC plastic, the shape of the particles is pentagonal, circular or triangular, the thickness of the particles is 0.2mm, and the maximum diameter of the particles (the maximum diameter of a polygon refers to the maximum diameter of its minimum enveloping circle) is 1.5 mm.

Embodiment 3

[0062] The anti-counterfeit label manufacturing equipment provided in this embodiment has roughly the same structure as that of Embodiment 1, the only difference is that in step b1 of this embodiment, the mixture of glue and particles loaded in the tank 44, the mixture of particles and glue The weight ratio is 0.6, the glue is UV-curable transparent glue, and the viscosity of the glue is controlled at 75 seconds when measured with Zion's No. 3 cup. The material of the particles is natural color aluminum, the shape of the particles is the letter O, D or G, the thickness of the particles is 0.8mm, and the maximum diameter of the particles (referring to the maximum diameter of the minimum enveloping circle) is 3mm.

[0063] The inventors have found out through many times of practice that the mixture of glue and particles has the best mixing degree and random distribution under the air pressure of 0.1-1.2 MPa, and the carrier 2 will not be damaged. When the particle and glue are i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com