Finite-element-based computer numerical control bender frame analysis method

An analysis method and finite element technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of long cycle test equipment, time-consuming and laborious, etc., to shorten the design cycle, save time and cost, and improve Use foreground effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

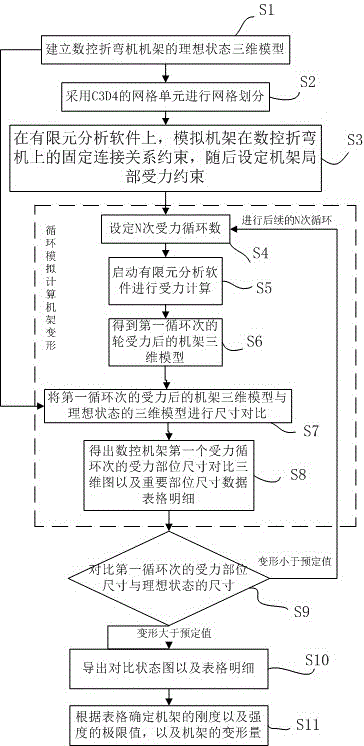

[0025] Such as figure 1 As shown, the analysis method of CNC bending machine frame based on finite element includes the following steps:

[0026] S1, establish the ideal state three-dimensional model of the CNC bending machine frame;

[0027] S2, using C3D4 grid units for grid division;

[0028] S3 On the finite element analysis software, simulate the fixed connection relationship constraints of the frame on the CNC bending machine, and then set the local force constraints of the frame;

[0029] S4-S8, cyclically simulate and calculate the deformation of the rack. After the first N cycles of simulating and calculating the force of the rack, record the deformation size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com