Turbine blade nonlinearity creep analysis method based on beam theory

A turbine blade and analysis method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the time-consuming 3D finite element creep analysis, difficult to adapt to multi-scheme, multi-working conditions, long-life blade design Analysis and real-time monitoring of blade life, low efficiency and other issues, to achieve the effect of convenient acquisition, improved acquisition efficiency, and good engineering practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

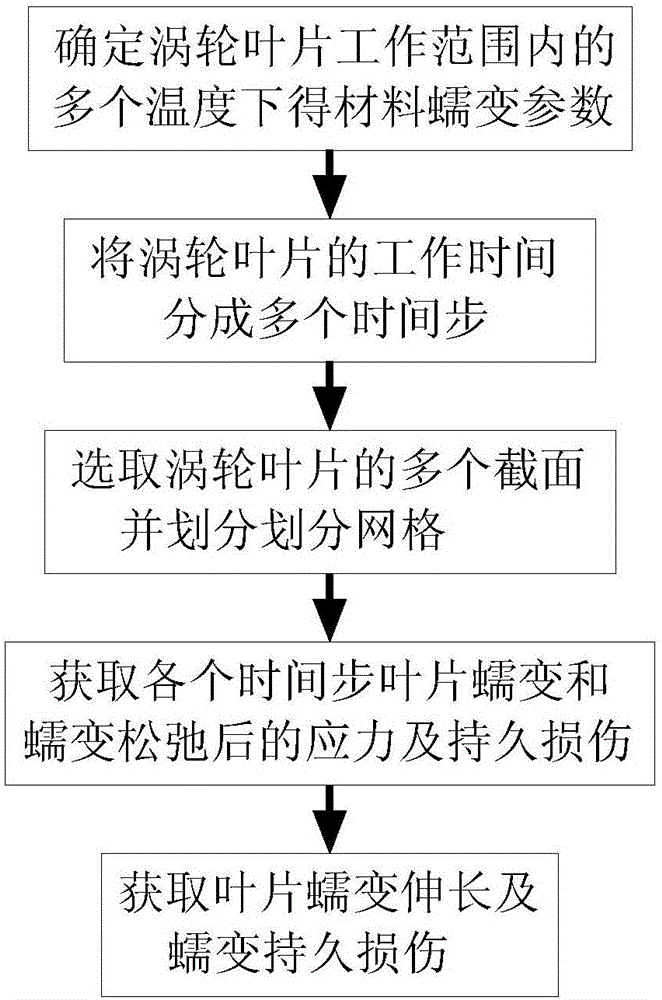

[0034] figure 1 It is a flow chart of the steps of the nonlinear creep analysis method of the turbine blade based on the beam theory in the preferred embodiment of the present invention. Such as figure 1 As shown, the nonlinear creep analysis method of the turbine blade based on the beam theory of the present embodiment includes the following steps: a, determining the material creep parameters at multiple temperatures within the working range of the turbine blade; Time is divided into multiple time steps; c. Select multiple sections of turbine blades and divide them into meshes; d. Based on beam theory, obtain the stress and permanent damage of blade creep and creep relaxation at each time step; e. Obtain blade Creep elongation and creep permanent damage. Optio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com