pid performance evaluation method

A performance and dynamic performance technology, applied in the direction of instruments, test/monitoring control systems, control/regulation systems, etc., can solve problems such as deterioration of control performance, reduction of product output, operating costs of unqualified products, etc., to reduce the probability of potential safety hazards , The effect of reducing the possibility of control performance deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

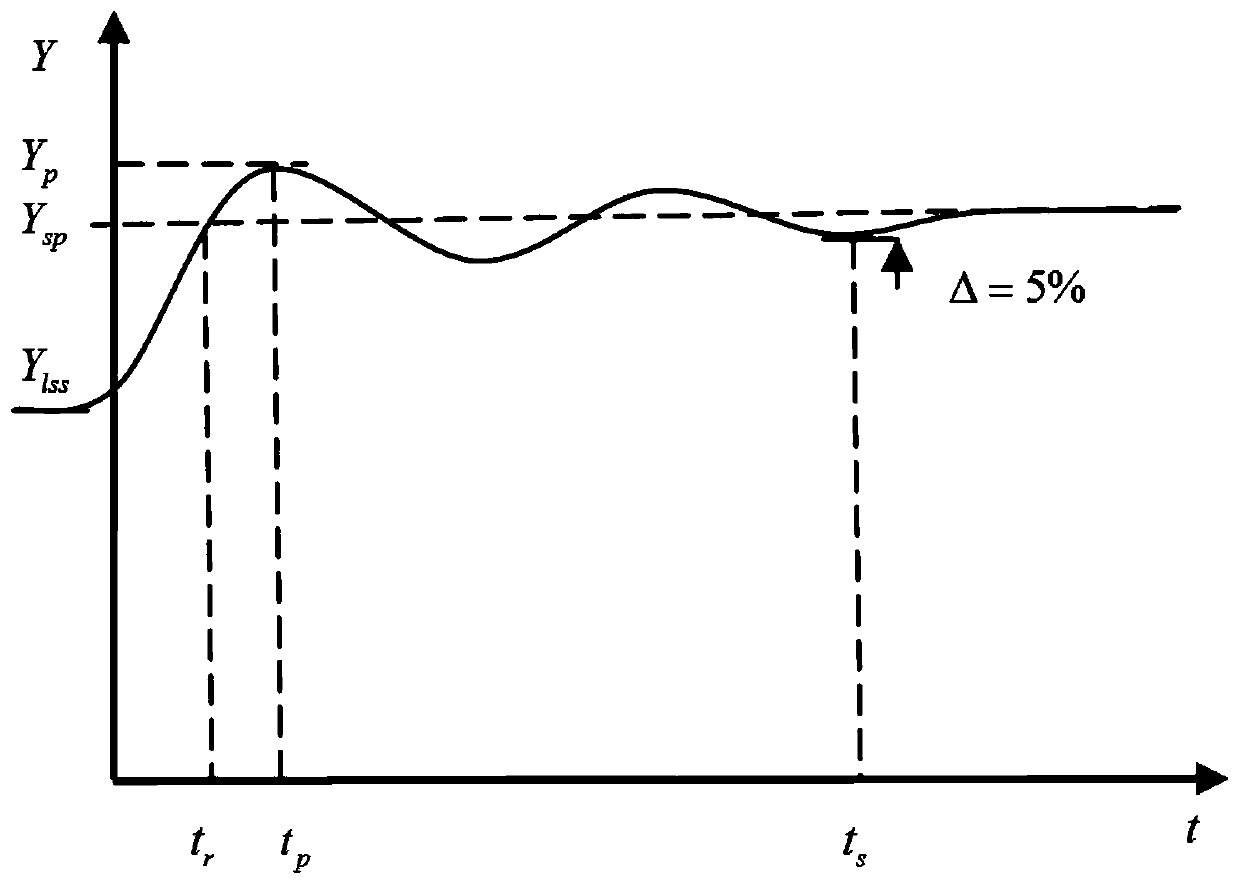

[0044] The invention provides a PID performance evaluation method, which is used for dynamic adjustment inside the DCS in the industrial automation process, and the corresponding time model is mainly preset in the control loop including temperature, liquid level and flow. In the adjustment process, the production data including the control loop measurement value, setting value and operation value are introduced, and the process model is constructed to update the response time of the DCS according to the production data, so that according to the updated response time Control the process in order to achieve the purpose of maintaining the best working condition.

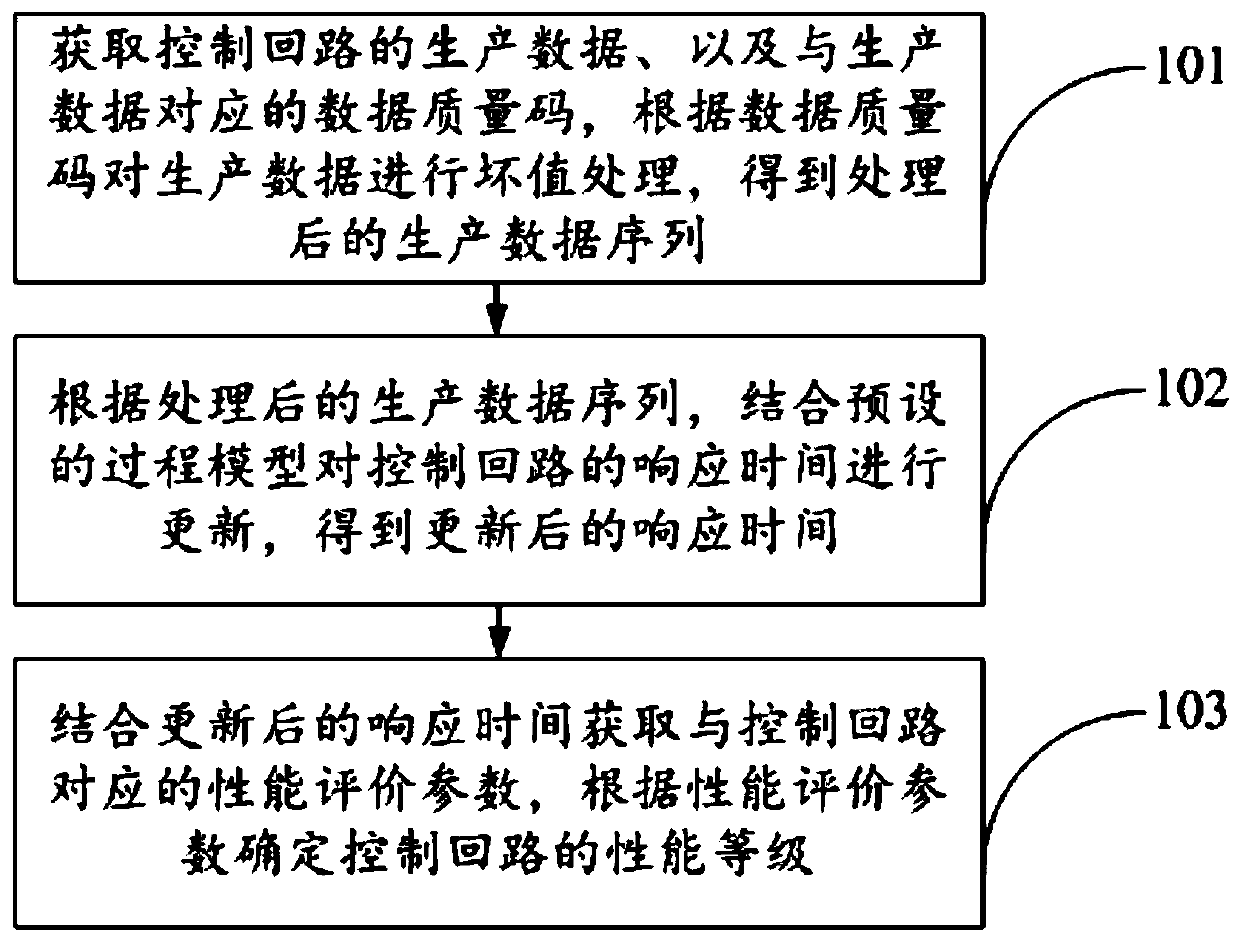

[0045] Such as figure 1 As shown, the PID performance evaluation method specifically includes:

[0046] 101. Obtain the production data of the control loop and the data quality code corresponding to the production data, perform bad value processing on the production data according to the data quality code, and obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com