CMOS sensor-based embedded correction system and correction method thereof

A CMOS sensor, embedded technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems that visible light sensors cannot meet comprehensive requirements, poor vibration accuracy, and poor anti-interference ability, making it more convenient to achieve system operation intelligence , the effect of improving precision and accuracy, improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

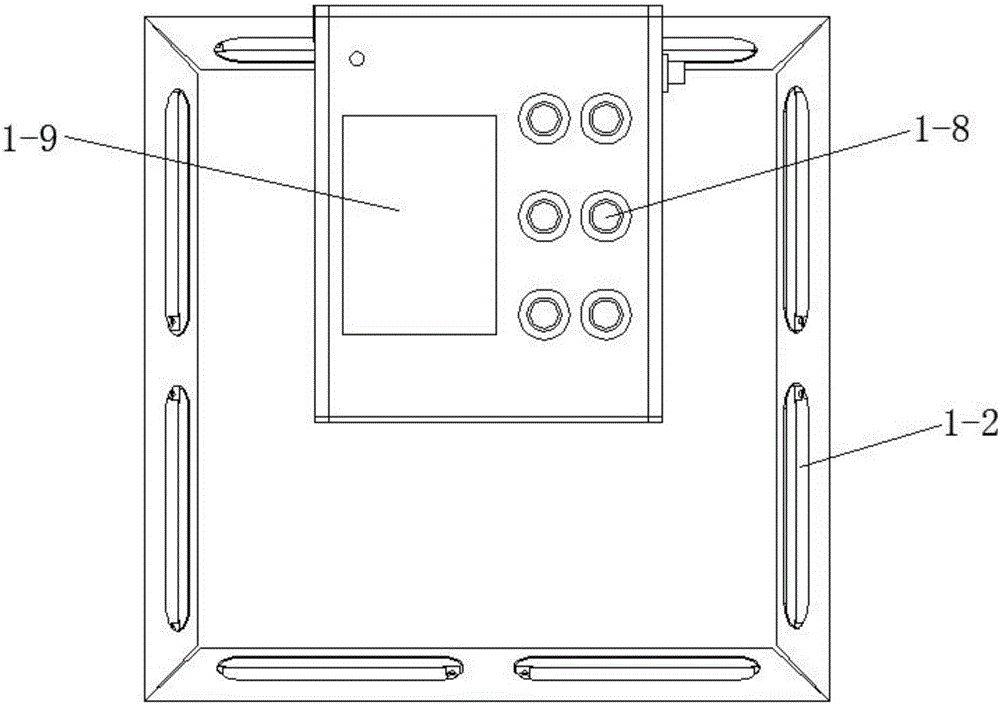

[0029] See Figure 1 to Figure 3 , The embedded deviation correction system based on CMOS sensor in this embodiment includes a deviation correction device 1 and a control box 2 .

[0030] The correction instrument 1 includes a bracket 1-1, a ring light source module 1-2 fixed on the bottom of the bracket 1-1, a housing 1-3 fixed on the upper part of the bracket 1-1 and located above the ring light source module 1-2, and arranged on the housing The STM32 main operation controller 1-4, the first bluetooth module 1-5 and the WiFi module 1-6 in the body 1-3, the CMOS image sensor 1-7 arranged on the lower end surface of the casing 1-3, arranged on the casing The state display on the upper end surface of the body 1-3 and the key control module 1-8 and the TFT liquid crystal display module 1-9. The ring light source module 1-2, the first Bluetooth module 1-5, the WiFi module 1-6, the CMOS image sensor 1-7, the status display and button control module 1-8 and the TFT liquid crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com