Method for preparing multilevel structure with compound period through variable angle exposure and application

A compound cycle and angle-changing technology, which is applied in microlithography exposure equipment, photomechanical equipment, and photolithography exposure equipment, etc., can solve the problems of low yield, limited scale difference, cumbersome steps, etc., and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

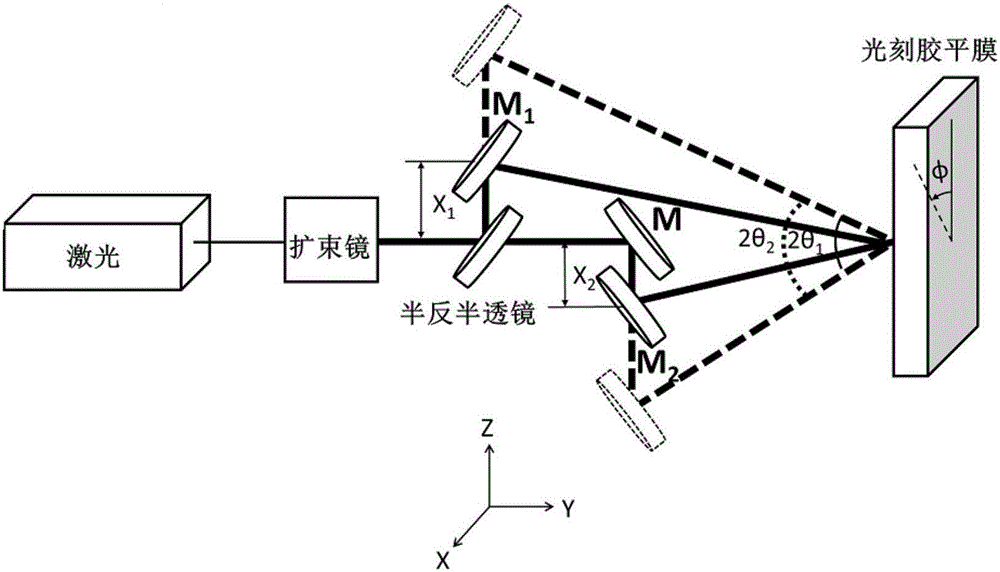

[0032] Fabrication of multilevel structures with recombination periods using variable-angle exposure.

[0033] Based on the principle of double-beam interference technology, the period and scale of each level of the exposed multi-level structure are determined by the exposure angle of the two laser beams. The specific value is given by the formula given. Therefore, as long as the exposure angle is selected according to the specific multi-level structure design, that is, according to the scale of each level structure, the multi-level structure can be obtained by sequentially exposing the sample.

[0034] The method for processing a multi-level structure with a composite period by using variable-angle exposure, the specific steps are as follows:

[0035] (1) Construction and debugging of laser optical path: the laser optical path used is a double-beam interference optical path, and the light source used is a continuous laser with a wavelength of 355nm; The optical path of "be...

Embodiment 2

[0042] The multi-level structure with recombination period was prepared by variable-angle exposure and applied to surface wettability control.

[0043] The introduction of micro-nanostructures on the surface of hydrophobic materials can improve the hydrophobicity of the material surface. Experiments have shown that the introduction of only a single micron or nanostructure has very limited improvement in hydrophobicity, and superhydrophobicity is often not achieved (the contact angle is required to be greater than 150°). Accordingly, the present invention can easily obtain a multi-level micro-nano structure with superhydrophobicity by utilizing the preparation method of variable-angle exposure.

[0044] The multi-level structure with recombination period prepared by variable-angle exposure is applied to the control of surface wettability. The specific method is as follows:

[0045] (1) Construction and debugging of laser optical path: The laser optical path used is a double-be...

Embodiment 3

[0051] Fabrication of multilevel structures with recombination periods by variable-angle exposure for structural color bionics.

[0052] The wings of butterflies and moths often have colorful colors called structural colors. This structural color comes from the diffraction of light by the complex periodic surface microstructures on the surface of such insect wings. Imitating the surface microstructure of butterfly wings, the multi-level structure of compound period prepared by variable-angle exposure can accurately simulate this biological structural color.

[0053] Using variable angle exposure to prepare a multi-level structure with a recombination period is applied to structural color bionics. The specific method is as follows:

[0054] (1) Construction and debugging of laser optical path: The laser optical path used is a double-beam interference optical path, and the light source used is a pulsed laser with a wavelength of 266nm; The optical path of "beam expansion-equal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com