Aminated mesoporous silica-glucose-manganese dioxide nanocomposite and preparation method and application thereof

A nanocomposite material and aminated mesoporous technology, applied in the field of nanomaterials, can solve the problems of low practicability of the sensing system and complicated design of the sensing system, and achieve the effects of reliable quantitative results, high sensitivity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Dissolve 0.5g of CTAB in 200mL of distilled water, add 1.75mL of 2.0M NaOH aqueous solution into the CTAB solution at 80°C, stir for 20 minutes, then drop 2.5mL of TEOS into it and stir for 2 hours, the product Filtered, washed with distilled water and methanol, and dried to obtain mesoporous SiO 2 (MSN).

[0038] MSN was refluxed in a solution consisting of HCl (37%, 1.5 mL) and methanol (75 mL) for 10 hours, then washed with distilled water and methanol, and dried under vacuum at 60 °C for 4 hours to remove excess CTAB, and the resulting 0.5 g MSN was dispersed in 10 mL of ethanol, and 500 μL of APTES was added thereto, and after stirring for 6 hours, the suspension was centrifuged and washed repeatedly with ethanol four times to obtain aminated MSN. The resulting aminated MSN is subjected to high-magnification transmission electron microscope detection, such as figure 2 shown.

Embodiment 2

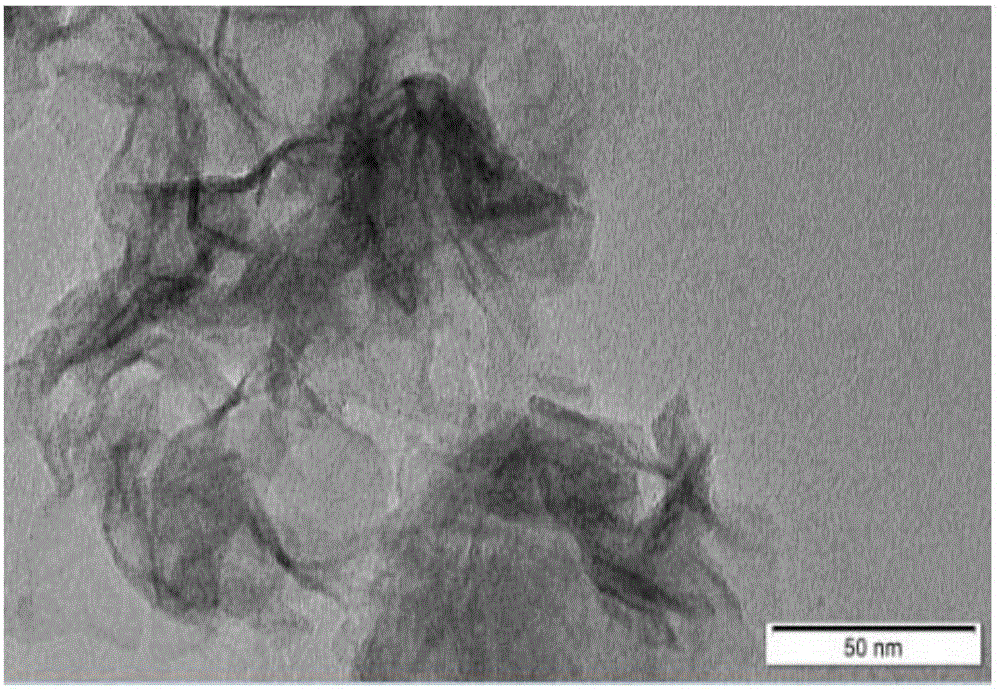

[0040] In a 50mL round bottom flask, within 15 seconds, 5mL of 0.3M MnCl 2 4H 2 O aqueous solution was mixed with 10 mL of 0.6 M tetramethylammonium hydroxide aqueous solution containing 3 wt % hydrogen peroxide, and the resulting mixture was stirred in air at room temperature for 12 hours, washed with deionized water and methanol, and dried at 50 °C. Disperse the dried resulting powder in water and sonicate for 10 h until a brown colloid is formed to obtain a concentration of 80 ug / mL of MnO 2 Nanosheets. Will get MnO 2 Nanosheets are subjected to high-magnification transmission electron microscopy, such as image 3 shown.

Embodiment 3

[0042] Disperse 5 mg of aminated MSN into 500 μL of 2.0 M glucose, shake the resulting mixture at room temperature for 16 h, and add 1 mL of MnO to the resulting suspension 2 nanosheets, the mixture was stirred at 4 °C for 8 hours, centrifuged, and washed with distilled water to obtain glucose-loaded MnO 2 End-capped MSN, SiO of the present invention 2 -Glucose-MnO 2 Nanocomposite material, the obtained nanocomposite material is subjected to high-magnification transmission electron microscopy detection, such as Figure 4 shown.

[0043] Glucose-loaded MnO 2 The capped MSN was dispersed in distilled water at a concentration of 20 mg / mL to form MnO at a concentration of 20 mg / mL 2 Blocked MSN in water.

[0044] To 50 μL of GSH aqueous solution of different concentrations (2 μM, 4 μM, 6 μM, 8 μM, 10 μM, 20 μM, 40 μM, 60 μM, 80 μM, 100 μM), add 100 μL of the above concentration of 20 mg / mL MnO 2 capped MSN in water. Incubate at room temperature for 10 minutes, shake the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com