Novel scanning method and novel scanning device of optical resolution photo-acoustic microscope

A technology of photoacoustic microscope and scanning method, which is applied in the direction of material analysis, measuring device and scientific instrument by optical means. The effect of noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 is the reflective scanning device of the present invention

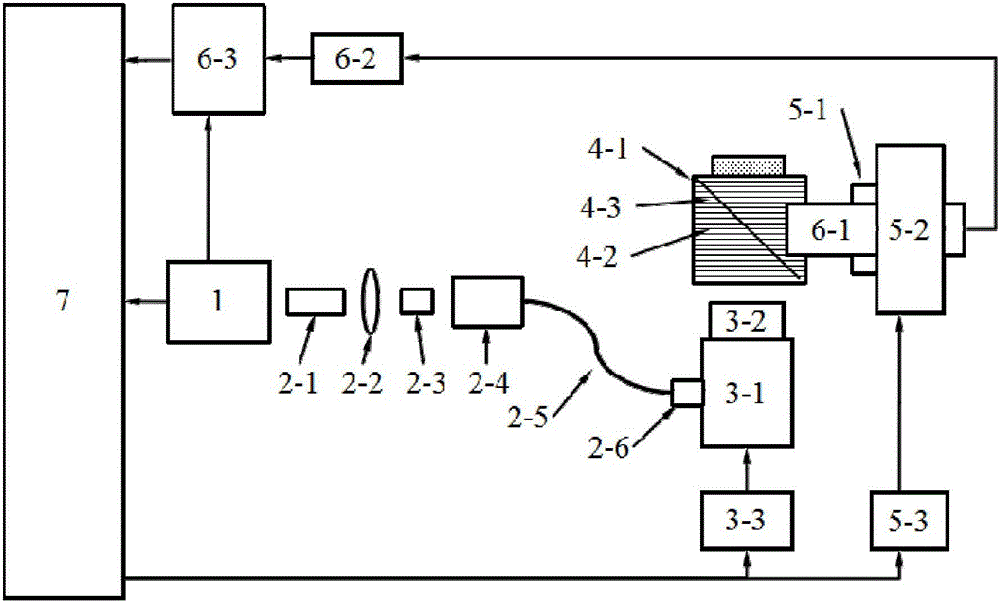

[0036]figure 1 It is a structural schematic diagram of a reflective scanning device, which includes a laser 1, a single-mode fiber coupling component, a two-dimensional scanning galvanometer system, a reflective support tank, an electronically controlled rotary table component, a signal acquisition component, and a computer.

[0037] Among them, the single-mode fiber coupling assembly is composed of a spatial light filter 2-1, a collimating lens 2-2, an objective lens 2-3, and a single-mode fiber coupling adjustment frame 2-4, which are sequentially installed coaxially with the pulse laser 1, and through a single The mode fiber 2-5 and the single-mode fiber collimating lens 2-6 are connected with the two-dimensional scanning vibrating mirror system 3-1; the scanning lens 3-2 is installed on the two-dimensional scanning vibrating mirror 3-1, and the computer 7 passes the scanning The mirror drive c...

Embodiment 2

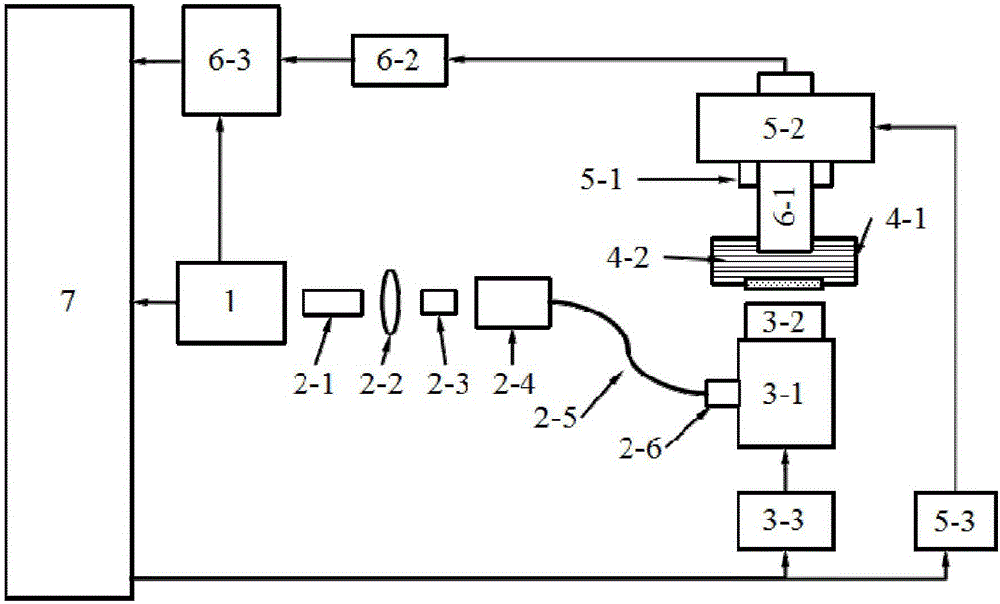

[0042] Embodiment 2 is the transmissive scanning device of the present invention

[0043] figure 2 It is a transmissive structure diagram of the device of the present invention, and its components are similar to those in Embodiment 1, the only difference is that a transmissive bracket water tank is used instead of a reflective bracket tank, and through holes are arranged on the upper and lower sides of the transmissive bracket tank, and the bottom The through hole is sealed with a transparent film and used as an imaging interface to ensure light transmission while the internal liquid does not leak. The imaging object is placed in this through hole; the upper through hole is used to place a line-focused ultrasonic detector. The imaging object is attached to the through hole at the bottom of the water tank 4-1 with a medical ultrasonic coupling agent, and the inside of the water tank is filled with an ultrasonic coupling liquid 4-2, and the water tank 4-1 is placed at the focal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com