Automatic conveyer of nuclear fuel microsphere granules and automatic detection platform

A transmission device and automatic detection technology, which is applied in the direction of measuring device, particle and sedimentation analysis, particle size analysis, etc., can solve the problems of long measurement time for detecting microsphere particles, high labor intensity of detection personnel, easy contact with radioactive hazards, etc., and achieve shortening The effect of detection time, simple structure, and few components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

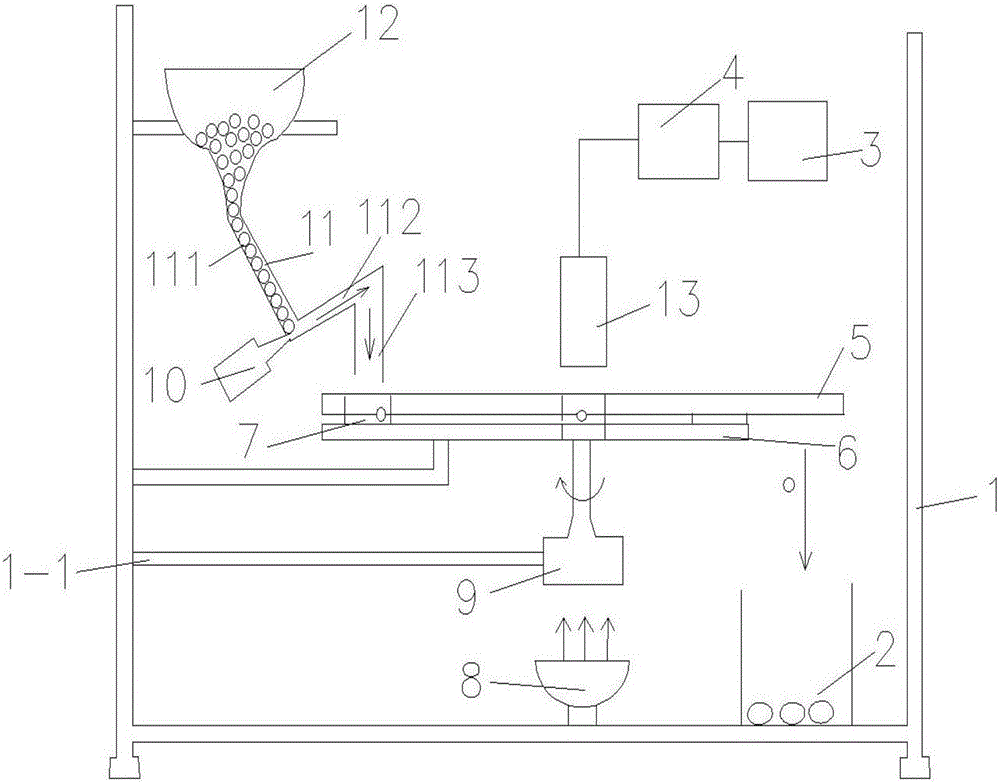

[0034] Such as figure 1 , figure 2 As shown, an automatic delivery device for nuclear fuel microsphere particles includes a funnel 12, and the outlet end of the funnel 12 is connected to a multi-section circular tube 11; the multi-section circular tube 11 includes a first circular tube 111 and a second circular tube 112 connected end to end in sequence , the third round pipe 113, the first round pipe 111 and the second round pipe 112 are V-shaped, the third round pipe 113 is vertically arranged downwards, the connection ends of the first round pipe 111 and the second round pipe 112 are arranged There is an air pump 10 that pushes the nuclear fuel microsphere particles from the second circular tube 112 into the third circular tube 113, and the outlet end of the third circular tube 113 is located at the upper end of the detection device for the number of nuclear fuel microsphere particles.

[0035] Wherein, the internal diameters of the first circular tube 111 and the second c...

Embodiment 2

[0038] An automatic detection platform with an automatic delivery device for nuclear fuel microsphere particles, such as figure 1 , figure 2 As shown, it includes a controller 3, an image data processing device 4, a light source 8, a stereo microscope 13, and a motor 9, and the controller 3 is electrically connected to the image data processing device 4, the light source 8, and the stereo microscope 13 respectively;

[0039] The controller 3 controls the rotation of the rotating shaft of the motor 9 and then drives the detection device to rotate. The detection device includes a transparent sample tray 6, and the light beam of the light source 8 irradiates the nuclear fuel microsphere particles in the transparent sample tray 6 from the lower end;

[0040] The stereo microscope 13 collects the projection data of the nuclear fuel microsphere particles in the transparent sample tray 6, and transmits the collected data to the image data processing device 4 for analysis and process...

Embodiment 3

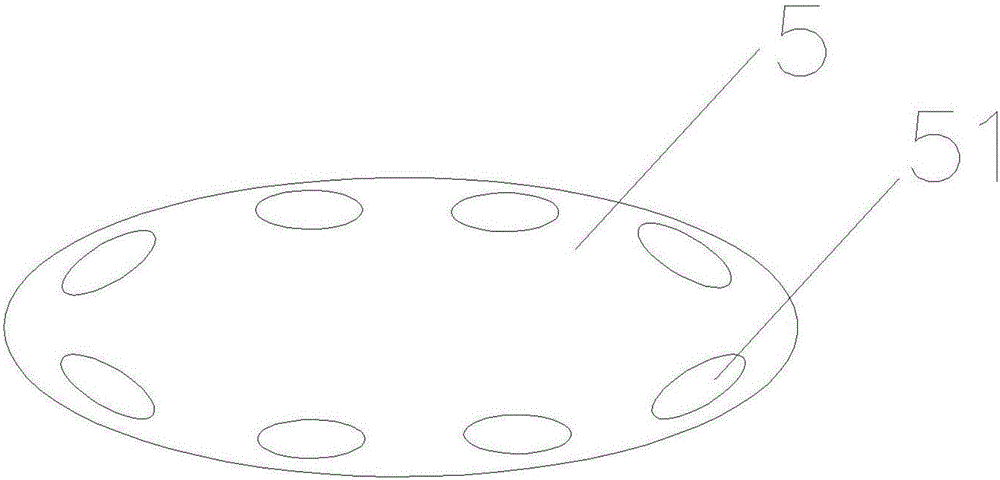

[0044] The present embodiment is further defined on the basis of the above-mentioned embodiments, the detection device also includes a transparent orifice plate 5, the center of the transparent orifice plate 5 is fixedly connected with the rotating shaft of the motor 9, and the edges of the transparent orifice plate 5 are equidistantly provided with a plurality of Circular holes 51, any one of the circular holes 51 is located below the outlet end of the third circular tube 113; the distance between the transparent sample tray 6 and the transparent orifice plate 5 is smaller than the minimum radius of the nuclear fuel microsphere particles.

[0045] Here, the structure of the detection device is specifically limited. The transparent orifice plate 5 has a hole, and the microsphere sample enters the transparent orifice plate 5, and is rotated and positioned under the drive of the motor 9, and the microsphere sample is quickly transferred to the stereo microscope 13. Check it out b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com