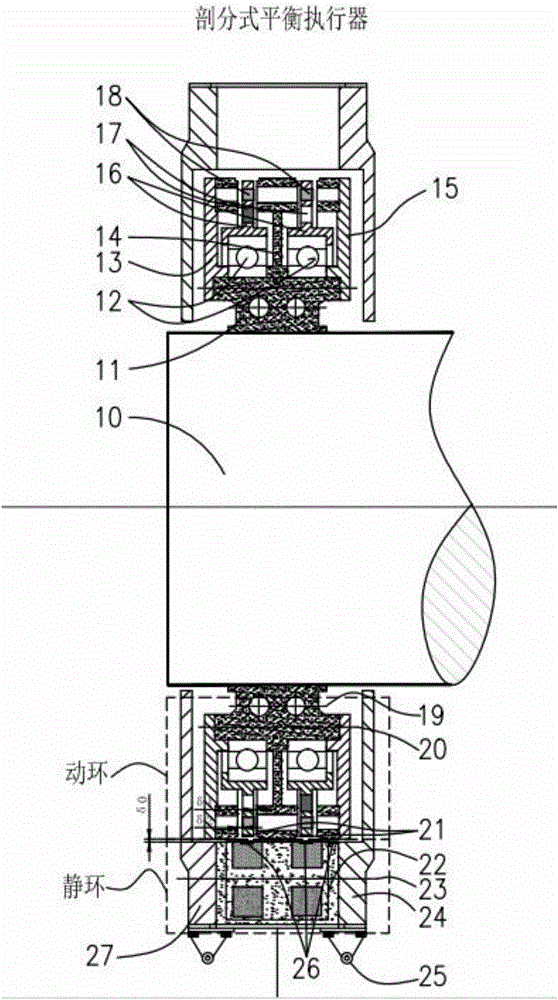

Split type automatic balancing device for realizing on-line automatic balance of rotating machine

A technology of automatic balancing and rotating machinery, which is applied in static/dynamic balance testing, measuring devices, testing of machine/structural components, etc. It can solve problems such as ring structures are difficult to install and disassemble, shorten downtime, unbalanced vibration, etc. , to achieve the effect of saving assembly time and resources, reducing maintenance costs, and solving the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] as attached figure 2 shown. The automatic balance actuator of the online automatic balance system of the present application can be installed at any position of the rotating main shaft 10, which is beneficial to achieve the best vibration suppression in the axial position. The installation process of the self-balancing actuator in the shaft-through installation method includes two parts: the installation of the split dynamic ring and the installation of the split static ring.

[0045] Among them, the installation process of the moving ring is as follows:

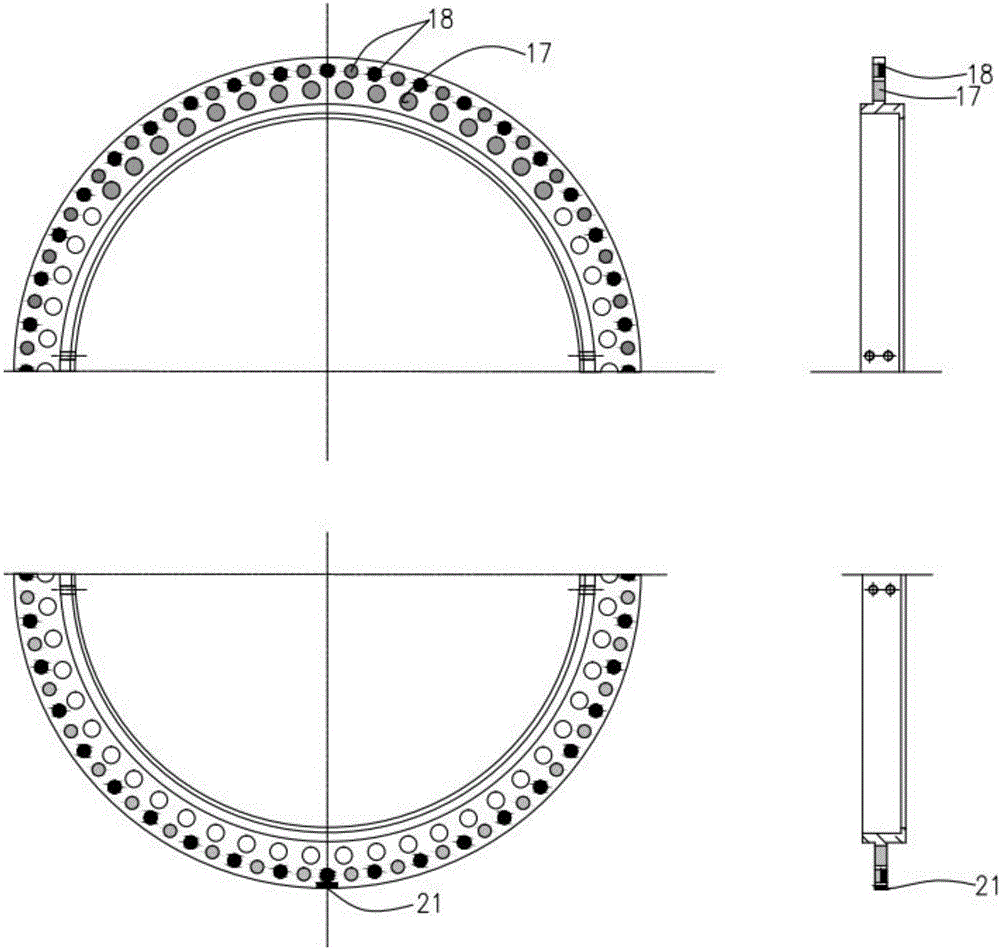

[0046] First of all, assembling the assembly weight plate 16 includes the following three steps:

[0047] (1) counterweight mass 17 is respectively installed on the 1 / 2 circumference of two counterweight plates 16; wherein, the size of the counterweight mass depends on the specific design;

[0048] (2) 2K stepping magnets 18 are installed on the counterweight plate 16 according to N and S pole crossings, the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com