Static blasting hole blowout prevention inventing method

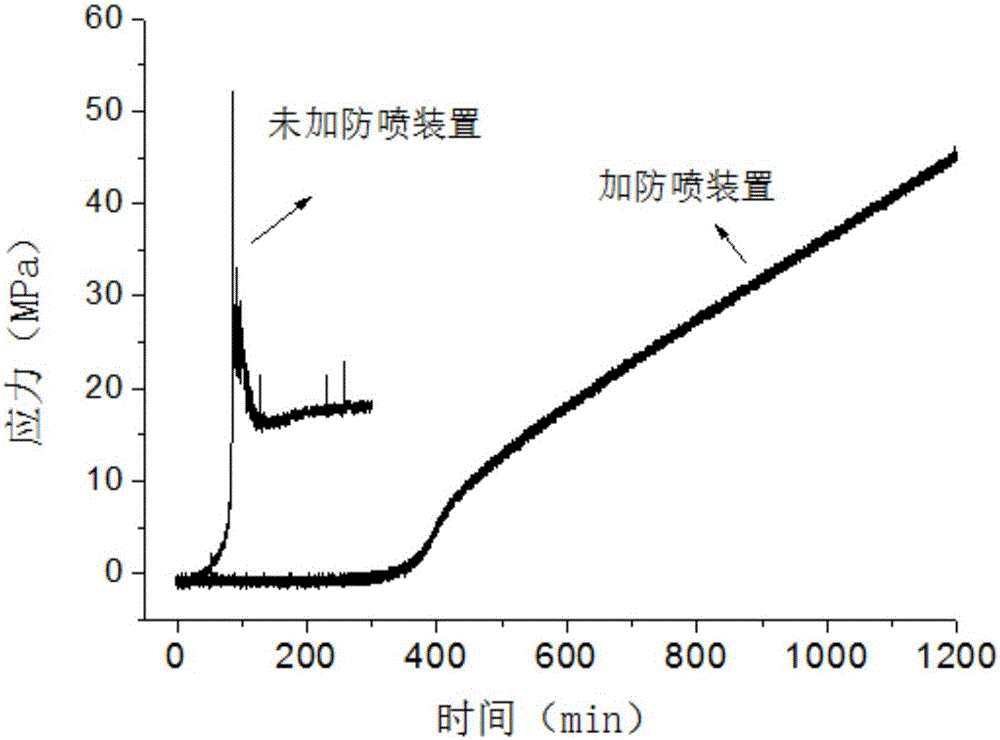

A static blasting and anti-blowout technology, applied in blasting and other directions, can solve the problems of life and health threats of construction workers, injuries caused by breaking agent spraying, and reduction of heat release rate, etc., and achieve the effect of small error, high accuracy and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples.

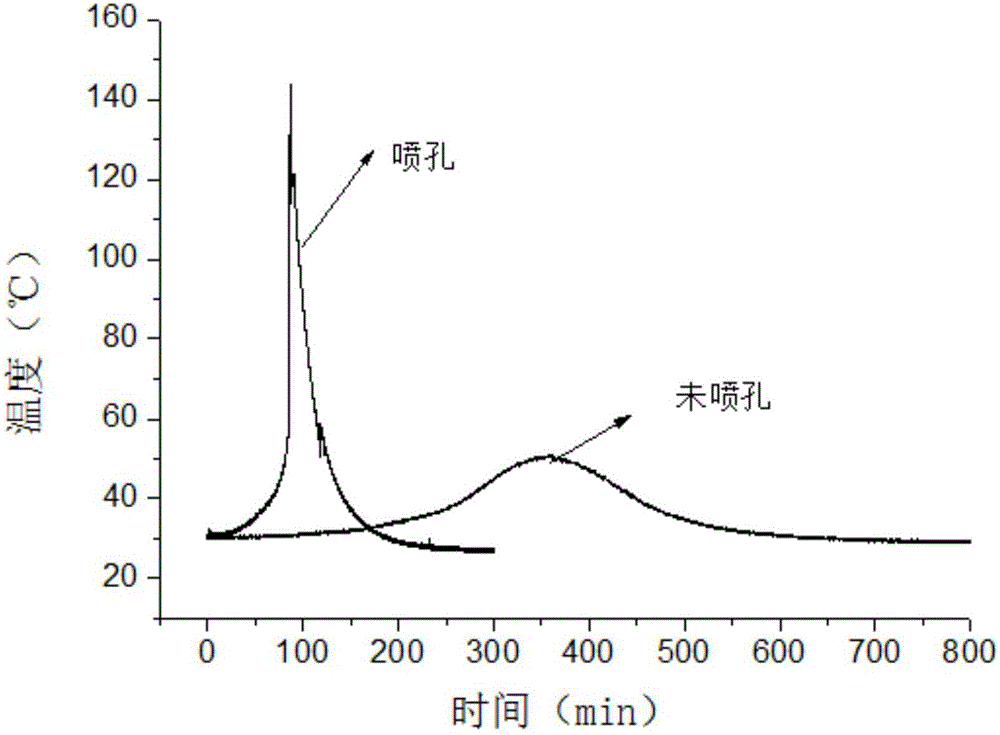

[0044] Such as figure 1 Shown is an example device for static blasting vents. The hole 1 described in the figure has a diameter of 29mm and a height of 300mm. The steel pipe 2 is made of 304 stainless steel. The adopted method of static blasting vent hole includes the following steps:

[0045] Step 1: Obtain the mass of water required to lower the silent breaker from 100°C to 70°C, and obtain it according to the following formula:

[0046] Q=cm(t 2 -t 1 )

[0047] In the formula, Q------heat generated by SCA, KJ;

[0048] c-------Specific heat capacity of water, J / (kg℃);

[0049] m------water mass, kg;

[0050] t 2 Take 100℃, t 1 Taking 70°C, calculate that the mass of water needed to lower the temperature from 100°C to 70°C is about 20g, that is, the volume of water required is 2.0×10 -5 m 3 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com