Mechanism, production equipment and method for drying bamboo stick incense

A bamboo stick incense, bamboo stick technology, applied in dryers, drying, progressive dryers and other directions, can solve the problems of bamboo stick incense material falling off, different drying speeds, affecting the quality of finished products, etc., to increase contact area, reduce the contact area, and ensure the effect of drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

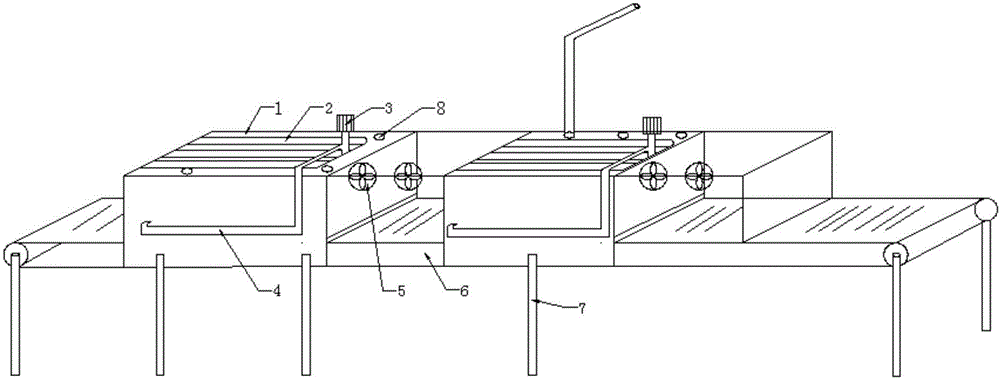

[0038] The mechanism for drying bamboo stick incense includes a transmission member that drives the bamboo stick incense to move from one end to the other end, and at least one set of covers for wrapping part of the transmission piece. According to the degree of humidity of the bamboo stick incense to be dried, the choice is made. Set the number of cover bodies, generally, choose to set 3 cover bodies 1, there is a space between the cover body 1 and the transmission part for the passage of bamboo stick incense, the cover body 1 is provided with an electric heating element, and the electric heating element can be energized There are dehumidification holes 8 on the surface of the cover body, and the dehumidification holes 8 are connected with the air outside the factory area through pipelines to avoid excessive humidity in the factory area; the cover body 1 is provided with a hollow metal heat pipe 2 with an opening at one end, and the heat pipe 2 is provided with a fan motor 3 a...

Embodiment 2

[0048] A bamboo stick incense production equipment, comprising a bamboo stick incense production machine, and a mechanism for drying bamboo stick incense is arranged below the outlet of the bamboo stick incense production machine, through the use of the bamboo stick incense production equipment, the bamboo stick incense production equipment is used. The bamboo stick incense is produced in the incense production machine. The bamboo stick incense falls on the transmission belt, and the bamboo stick incense is dried in the cover to remove the moisture. There is no need for manual contact with the bamboo stick incense, and the wet surface material of the bamboo stick incense is avoided. Being stuck, the yield of bamboo stick incense is high.

[0049] The using method of above-mentioned a kind of bamboo stick incense production equipment, concrete steps are as follows:

[0050] 1) The bamboo stick incense production machine produces bamboo stick incense, and the bamboo stick incens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com