Hotpot stove

A technology for stoves and hot pots, applied in household stoves/stoves, lighting and heating equipment, sustainable buildings, etc., can solve problems such as unreasonable furnace core structure design, unfavorable charcoal combustion efficiency, and charcoal blocking ventilation openings, etc., to achieve stability High, improve combustion efficiency, increase the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

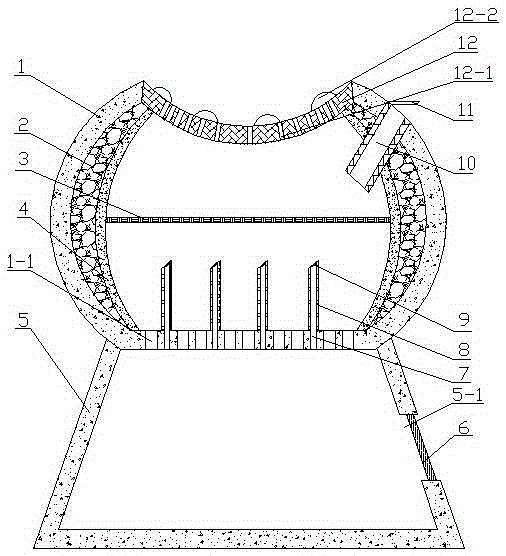

[0022] As shown in the accompanying drawings: a hot pot stove includes an upper furnace body 1 and a lower furnace body 5, the side wall of the upper furnace body 1 is an arc-shaped structure, the upper furnace body 1 is provided with a furnace 4, and the furnace 4 is provided with a furnace bridge 3. The lower furnace body 5 has a hollow terrace structure. The lower furnace body 5 is provided with a first opening 5-1, and the first opening 5-1 is provided with an adjustable furnace door 6. The furnace door 6 is formed by Composed of a push-pull plate and a chute with a scale, it is easy to operate and control. The connection between the lower furnace body 5 and the upper furnace body 1 is provided with a number of columns 8 and ash outlet holes 1-1, and the inside of the column 8 is provided with ventilation holes 7. , the ventilation hole 7 passes through the bottom of the upper furnace body 1, the upper surface of the column 8 is an inclined structure, and the upper surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com