Device for preventing downwash of smoke plume for chimney

A chimney and smoke prevention technology, applied in the field of chimneys, can solve problems such as chimney freezing, achieve the effects of avoiding contact, reducing energy consumption and operation and maintenance costs, and raising the height of smoke plumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The type of chimney in this embodiment is a brick inner tube chimney, the outer tube of the chimney is made of reinforced concrete, and the inner tube of the chimney is made of acid-resistant bricks. The inner tube of the chimney is 210m high, the outlet diameter is 7.5m, and the flue gas treatment capacity under 100% load of the unit is 3624074m 3 / h, the minimum operating load of the unit is 45%, the wind speed at the outlet of the chimney inner tube is 8.7m / s, and the smoke density is 1.025kg / m 3 , the air density is 1.17kg / m 3 .

[0037] First of all, according to the above parameters, a three-dimensional mathematical model of the wet chimney is established, and through CFD fluid simulation, it is predicted that the unit load of the chimney is below 75%, and there will be smoke plume downwashing.

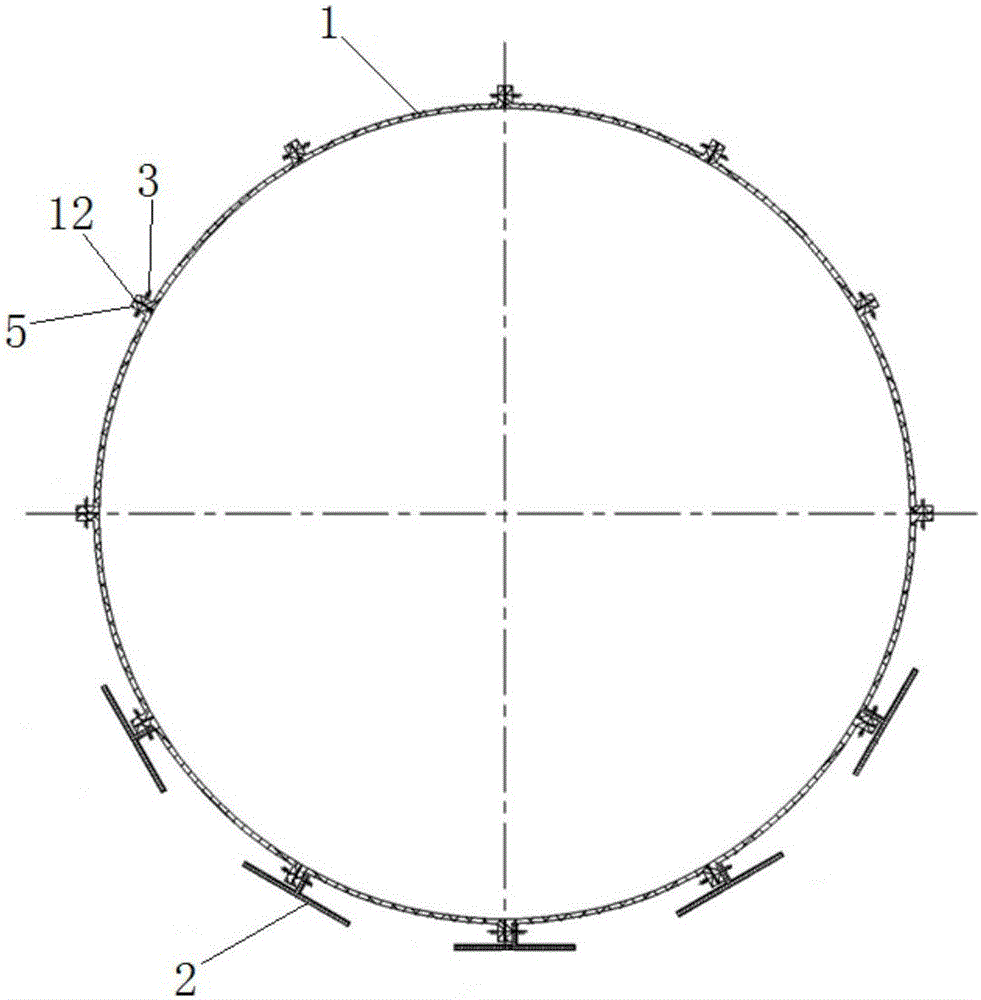

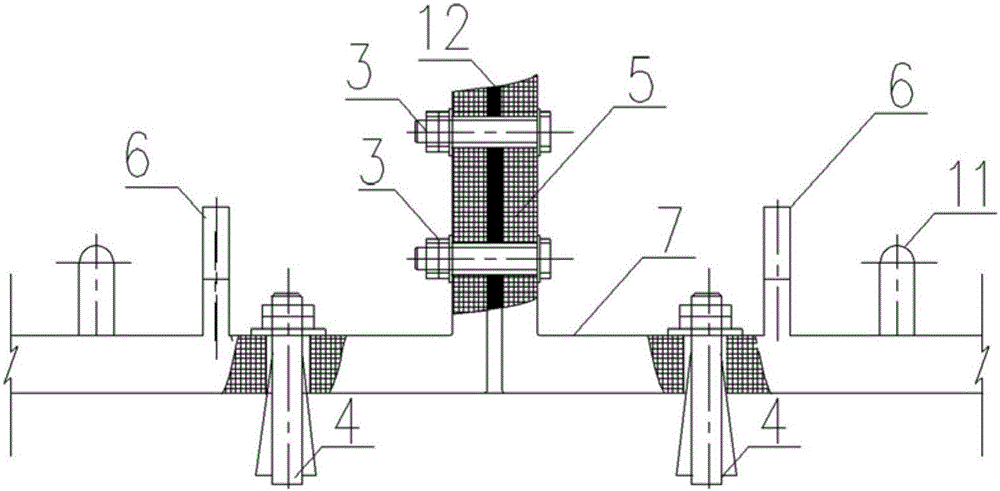

[0038] Next, the trajectory and influence range of plume downwashing at the minimum operating load are determined through CFD fluid dynamics simulation; further, the st...

Embodiment 2

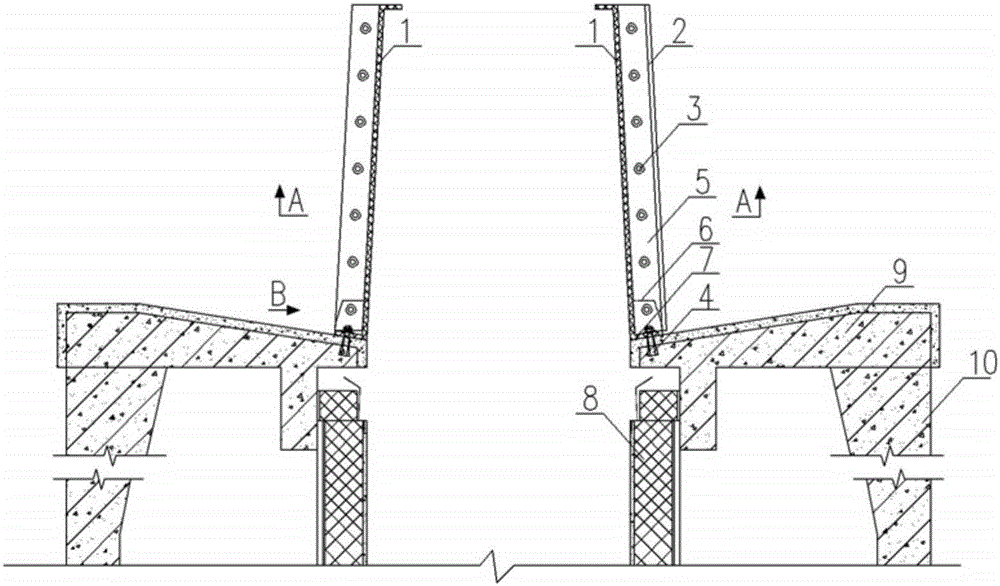

[0051] Figure 5 It is a schematic installation diagram of a device for preventing smoke plume downwashing of a chimney in this embodiment; its A-A cross-sectional view is the same as figure 2 .

[0052] The difference between this embodiment and Embodiment 1 is that this device is applied to a single-tube concrete chimney, and the chimney includes a masonry inner lining 18, a heat insulation layer 16, an outer cylinder 10 of the chimney and a concrete topping 9 of the chimney.

Embodiment 3

[0054] Figure 6 It is an installation schematic diagram of a device for preventing smoke plume downwashing of a chimney according to this embodiment; Figure 7 yes Figure 6 A-A sectional view of .

[0055] The difference between this embodiment and the previous two embodiments is:

[0056] (1) The device is applied to a steel inner tube chimney, which includes a chimney inner tube 8, a chimney outer tube 10, ultra-fine glass wool 17 and a rain cover 19. The chimney outer cylinder 10 is made of reinforced concrete, and the chimney inner cylinder 8 is a steel inner cylinder.

[0057] (2) The materials of the necking 1 and the windshield 2 of this embodiment are different from those of the first two embodiments. In this embodiment, the necking 1 and the windshield 2 are made of steel inner cylinder; The space is connected by welding, the necking 1 and the steel inner cylinder are fixed by welding, and the windshield 2 and the necking 1 are fixed by welding.

[0058] (3) In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com