Shuttle valve for refrigerator compressor

A technology for refrigerator compressors and shuttle valves, applied to machines/engines, lift valves, valve details, etc., which can solve the problems of short service life, slow sealing speed, and reduced work efficiency of shuttle valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

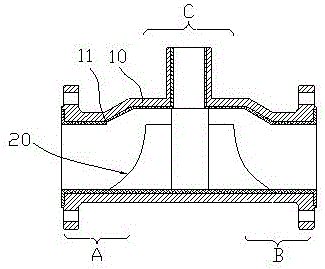

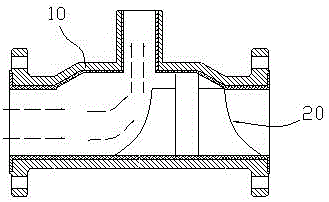

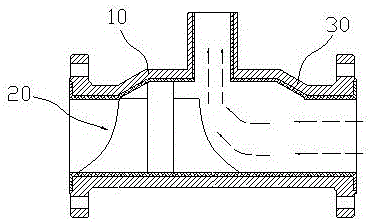

[0011] Combine below Figures 1 to 4 The present invention is described in further detail.

[0012] A shuttle valve for a refrigerator compressor, including a valve body 10 and a valve core 20, the valve body 10 includes a middle pipeline C and first and second air intake pipelines A and B connected to the middle pipeline C, the The pipe diameters of the first and second air intake pipelines A and B are smaller than the pipe diameter of the middle pipeline C. The valve core 20 includes a core body 21 and two core heads 22 positioned at the end faces of the core body 21. The core heads 22 are in the form of Wedge-shaped and facing the intake direction, a step 11 is provided at the junction of the first and second intake pipelines A, B and the middle pipeline C.

[0013] The core head 22 is wedge-shaped and faces the air intake direction. The core head 22 can minimize the flow resistance of the gas, and the middle section pipeline C with a large diameter increases the cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com