Active and semi-passive composite vibration isolator

A vibration isolator, semi-passive technology, applied in spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problems of high control cost, unstable system, difficult to achieve system wide frequency, complex frequency, etc. Compressive characteristics and output force, good low-frequency characteristics, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

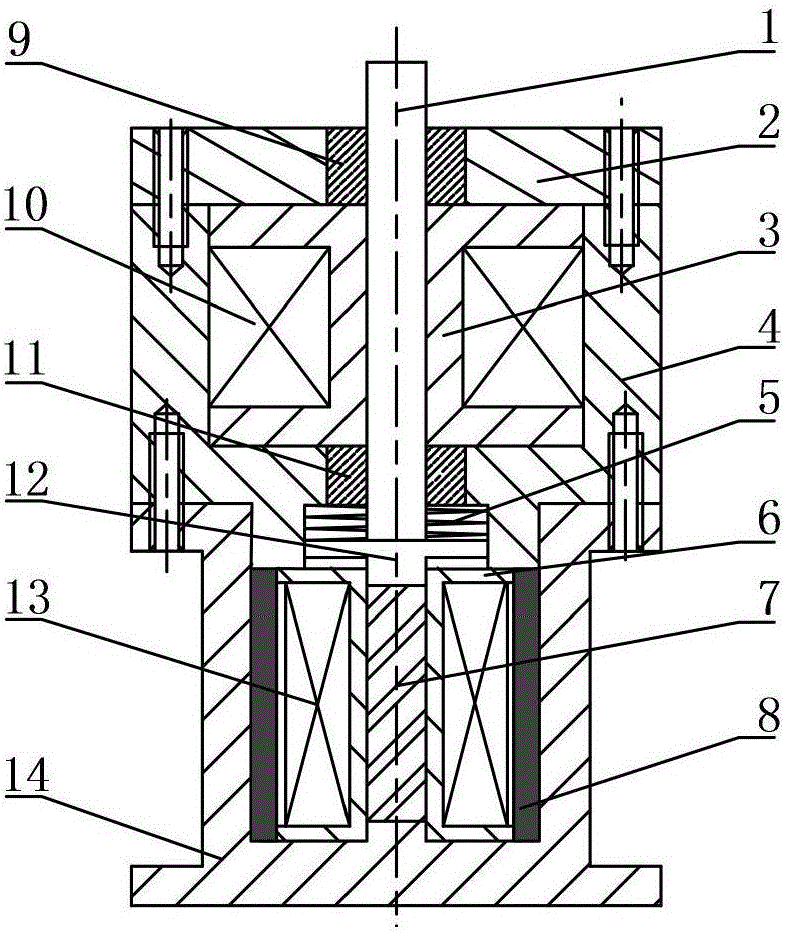

[0035] see figure 1 , the structural relationship is as follows: the magnetostrictive unit and the magneto-rheological elastomer unit are arranged inside the frame of the composite vibration isolator, the magnetostrictive unit is arranged under the magneto-rheological elastomer unit, the two are connected in series, and the magnetostrictive The unit, the magnetorheological elastomer unit and the composite vibration isolator frame together constitute the composite vibration isolator;

[0036] The magnetostrictive unit includes a reset preload spring 5, a lower coil bobbin 6, a magnetostrictive rod 7, a permanent magnet 8, a push rod 12 and a lower excitation coil 13;

[0037] The magnetostrictive rod 7 is fixed in the frame of the composite vibration isolator, the lower excitation coil 13 is arranged on the periphery of the magnetostrictive rod 7 through the lower coil frame 6, the permanent magnet 8 is cylindrical, and is sleeved on the lower excitation coil 13 and the lower c...

Embodiment 2

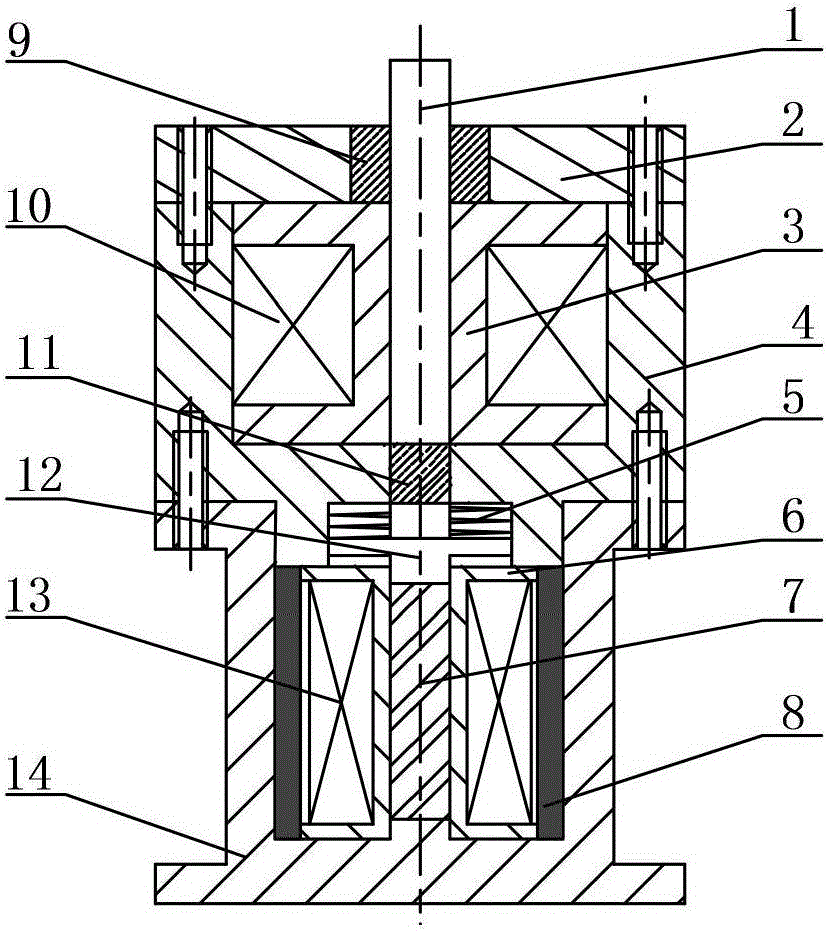

[0047] see figure 2 , the structural relationship is as follows: the magnetostrictive unit and the magneto-rheological elastomer unit are arranged inside the frame of the composite vibration isolator, the magnetostrictive unit is arranged under the magneto-rheological elastomer unit, the two are connected in series, and the magnetostrictive The unit, the magnetorheological elastomer unit and the composite vibration isolator frame together constitute the composite vibration isolator;

[0048] The magnetostrictive unit includes a reset preload spring 5, a lower coil bobbin 6, a magnetostrictive rod 7, a permanent magnet 8, a push rod 12 and a lower excitation coil 13;

[0049] The magnetostrictive rod 7 is fixed in the frame of the composite vibration isolator, the lower excitation coil 13 is arranged on the periphery of the magnetostrictive rod 7 through the lower coil frame 6, the permanent magnet 8 is cylindrical, and is sleeved on the lower excitation coil 13 and the lower ...

Embodiment 3

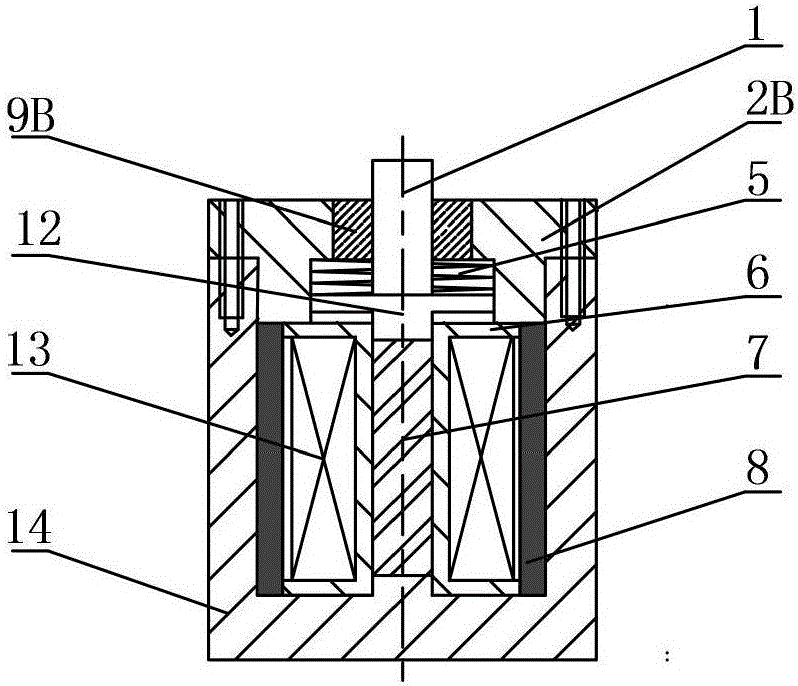

[0059] see image 3 , the structural relationship is as follows: the magnetostrictive unit and the magnetorheological elastomer unit are arranged inside the frame of the composite vibration isolator, the magnetostrictive unit is arranged under the magnetorheological elastomer unit, the magnetostrictive unit, the magnetorheological elastomer unit The unit and the composite vibration isolator frame together constitute the composite vibration isolator;

[0060] The magnetostrictive unit includes a reset preload spring 5, a lower coil bobbin 6, a magnetostrictive rod 7, a permanent magnet 8, a push rod 12 and a lower excitation coil 13;

[0061] The magnetostrictive rod 7 is fixed in the frame of the composite vibration isolator, the lower excitation coil 13 is arranged on the periphery of the magnetostrictive rod 7 through the lower coil frame 6, the permanent magnet 8 is cylindrical, and is sleeved on the lower excitation coil 13 and the lower coil Outside the skeleton 6, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com