Clutches for multi-speed automatic transmissions

A technology for automatic transmissions and clutches, applied in fluid-driven clutches, non-mechanical-driven clutches, clutches, etc., can solve the problems of long axial length of the clutch part, longer axial dimension of the transmission, and unfavorable layout of the whole vehicle, etc., to achieve shaft The effect of shortening the size, reducing the axial length, and compressing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention is not limited to this embodiment. In order to provide the public with a thorough understanding of the present invention, specific details are specified in the following preferred embodiments of the present invention.

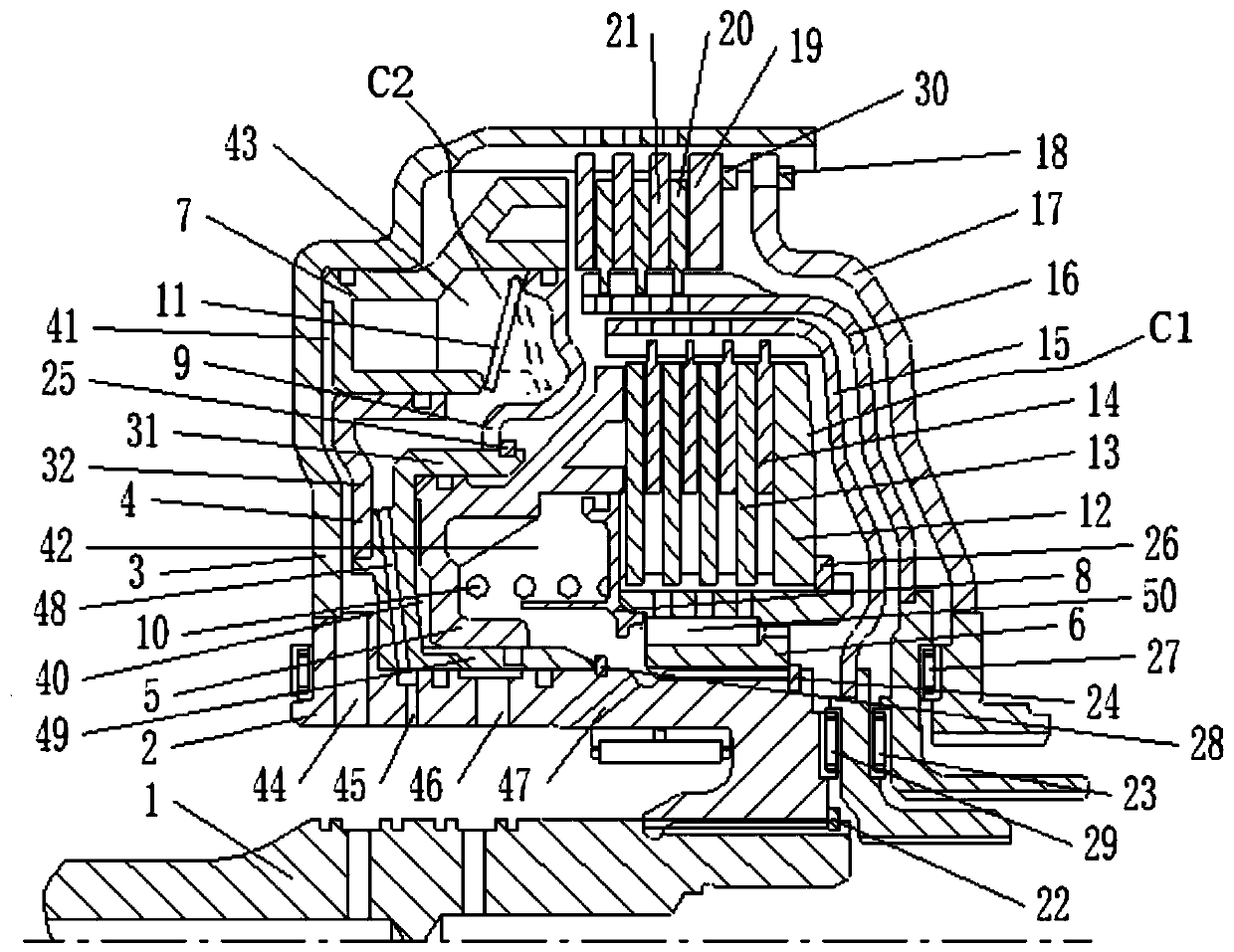

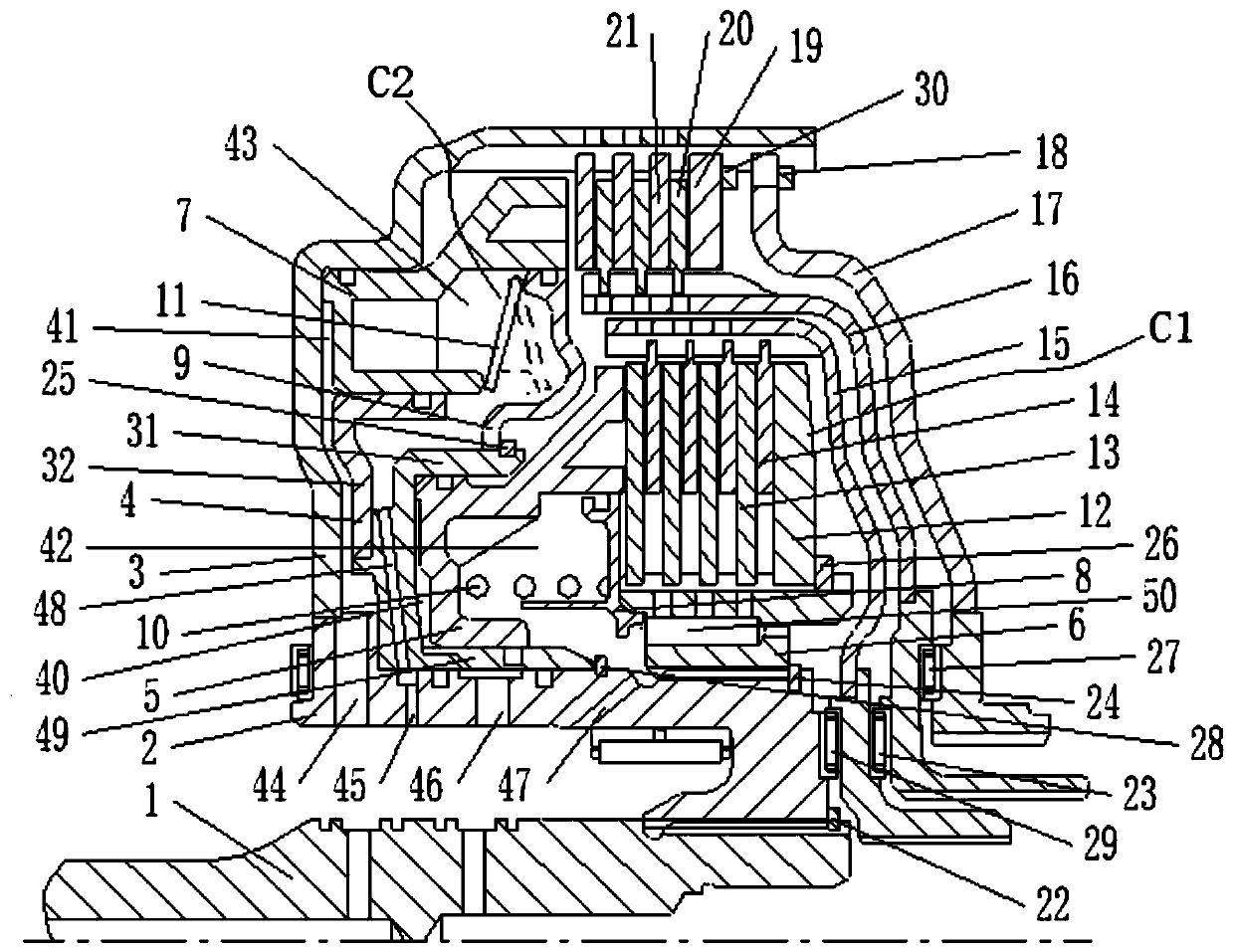

[0037] like figure 1 As shown, a clutch for a multi-gear automatic transmission includes two groups of clutches (first clutch C1 and second clutch C2), input shaft 1, support shaft 2, piston housing 4 and sun gear input hub 17; the first clutch Including the first piston 5, the first balance piston 8, the first friction plate 14, the first dual plate 13, the first back plate 12, the first return spring 10, the first input hub 6 and the first output hub 15; The second clutch includes a second piston 7, a second balance piston 9, a second friction plate 20, a second counter plate 21, a second back plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com