Double-main-control-valve integrated jet pipe servo valve

A servo valve and dual master control technology, applied in the field of servo valves, can solve the problems of system inability to guarantee stability and fault sensitivity, and achieve the effects of small control resistance, consistent flow output characteristics, and strong mechanical maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through specific examples.

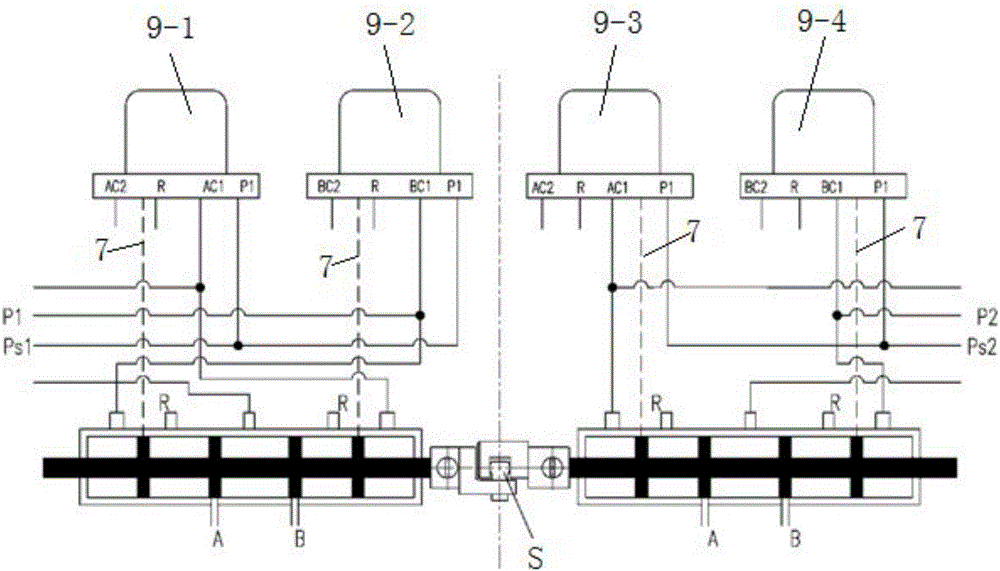

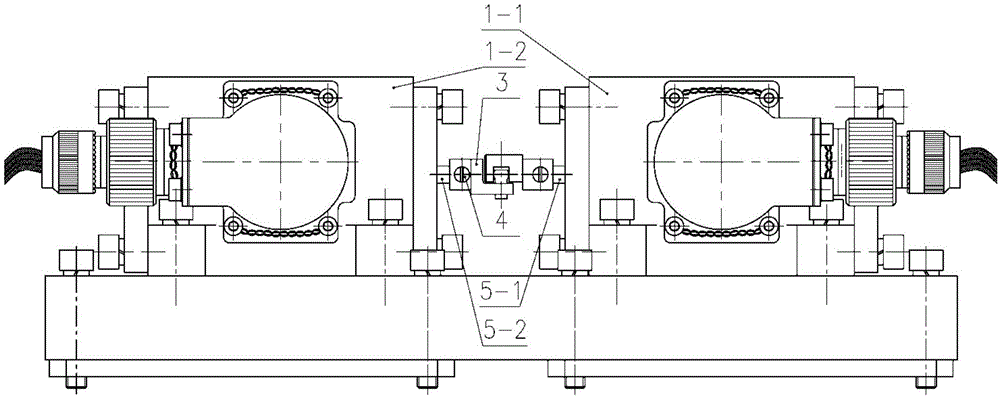

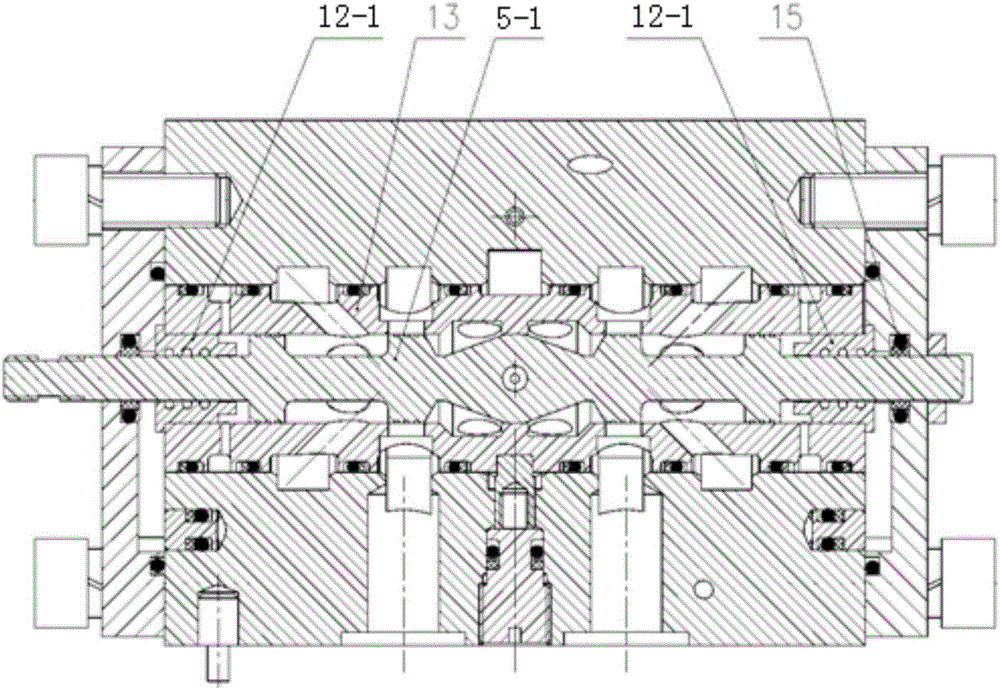

[0028] see Figure 1~Figure 5 , the dual main control valve integrated jet pipe servo valve (hereinafter referred to as the integrated servo valve) of the present invention includes two two-stage servo valves A1-1 controlled by independent hydraulic fluids, two-stage servo valves B1-2, spool coupling Device 3, clamping screw 4. from figure 2 It can be seen that the two-stage servo valve A1-1 and the two-stage servo valve B1-2 connect the two spools A, B5-1, and 5-2 through the coupling 3 to form an integrated servo valve. A mechanical control interface is reserved, and if both the two-stage servo valve A1-1 and the two-stage servo valve B1-2 are in a fault state, the integrated servo valve is controlled through the mechanical control interface. The control pressure output ports AC1 and AC2 of the two pilot stage components 6-1 in the two-stage servo valve A1-1, the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com