Fuel injection simulation experiment system capable of continuously regulating pressure and temperature

A technology of fuel injection and pressure adjustment, which is applied in the direction of fuel injection device, charging system, engine test, etc. It can solve the problems of limited system simulation working conditions and inability to simulate working conditions and environment, and achieve a wide range of fuel temperature adjustment, Compact structure, high pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

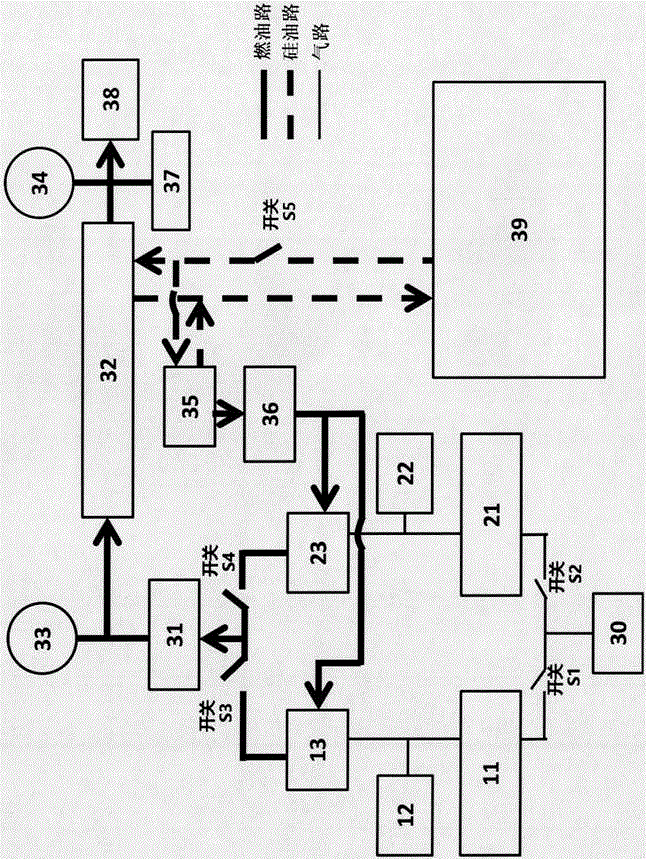

[0043]The fuel injection test system with adjustable pressure and temperature is mainly composed of a gas cylinder 30 (for example, the internal gas pressure is 10-20MPa, especially 15MPa), a pressure regulating valve 11 (for example, the pressure adjustment range is 0-10MPa), a low-pressure release valve 12, a low-pressure Oil pump 13 (for example, the pressure ratio is 1:1), pressure regulating valve 21 (for example, the pressure adjustment range is 0-1MPa), high pressure relief valve 22, high pressure oil pump 23 (for example, the pressure ratio is 1:80), filter 31, heat Exchanger 32, oil pressure gauge 33, oil temperature gauge 34, oil tank 35, oil filter 36, oil drain valve 37, fuel injector 38, integrated cooling and heating machine 39, switch S1~S5 is formed. Due to the small pressure ratio of the low-pressure fuel pump, a relatively large initial air pressure is required to pressurize the fuel, and the maximum adjustment range of the corresponding pressure regulating va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com