Direct injection gasoline engine combustion system and control method

A combustion system and control method technology, applied in engine control, combustion engines, mechanical equipment, etc., can solve problems such as combustion stability and unfavorable emission results, weakening the flow strength of the mixture, and multiple oil films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

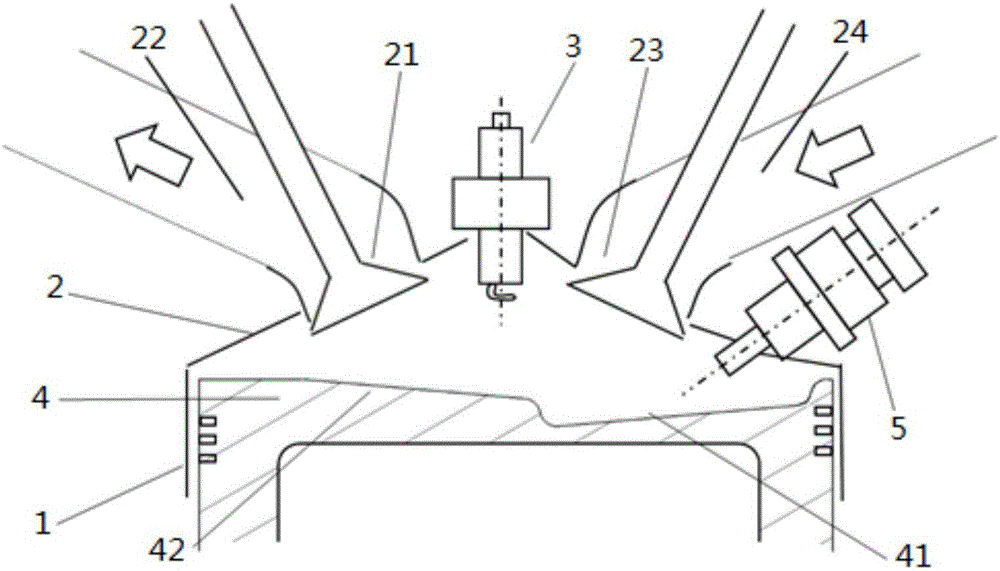

[0026] In the first embodiment of the present invention, the combustion control of the engine adopts two fuel injection strategies. When the first injection time is between 240°CA and 300°CA before the compression top dead center, the second injection time is between 120°CA and 300°C before the compression top dead center. Between 180°C and CA; the fuel ratio of the first injection is 60% to 90%, the fuel ratio of the second injection is 10% to 40%, and the sum of the fuel ratio of the two injections is 100%.

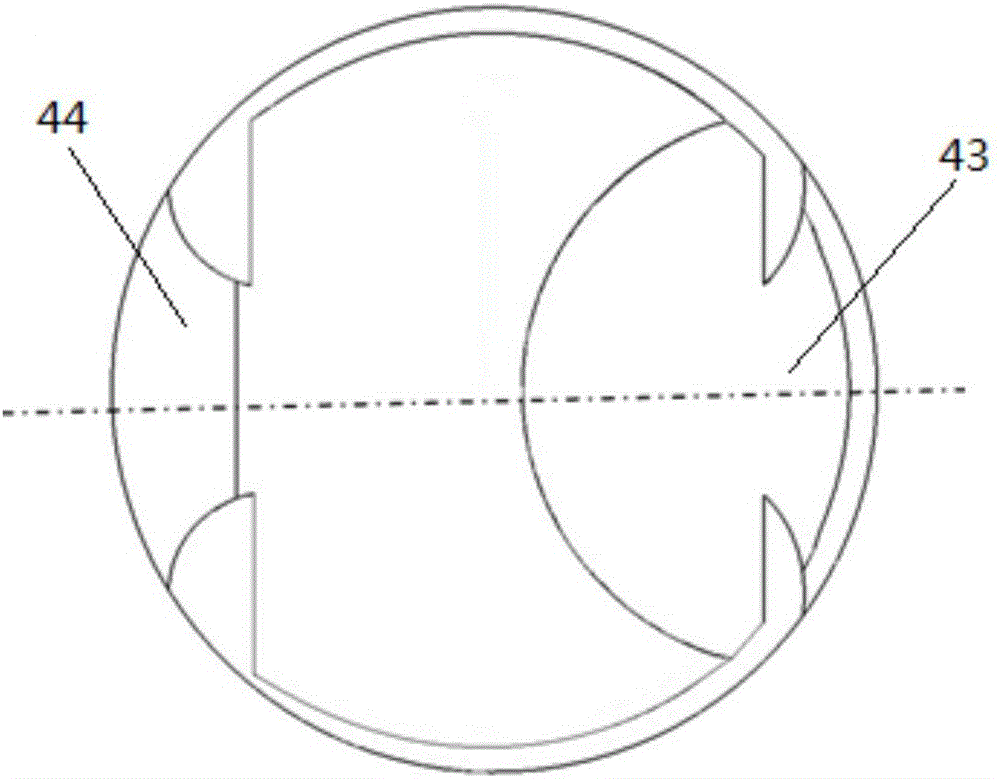

[0027] In the first embodiment, when the fuel injector 5 injects oil for the first time, the oil beam will touch the first dimple 41 , and when the fuel injector 5 injects fuel for the second time, the oil beam will only touch the second dimple 42 . Since there is no protrusion on the piston of the traditional direct-injection gasoline engine between the first pit and the second pit, it will not hinder the airflow movement on the piston surface, which is beneficial to th...

no. 3 example

[0029] In the third embodiment of the present invention, the combustion control of the engine adopts a three-time fuel injection strategy. between ℃CA; the third injection time is between 120℃CA and 150℃CA before compression top dead center; The ratio is 5% to 20%, and the sum of the fuel ratios of the three injections is 100%.

[0030] According to the compression ratio of different engines, the size of the combustion chamber, the law of intake and exhaust, and the fuel injection law of the injector, the injection timing, injection pulse width, injection pressure and ignition timing should also be optimized accordingly to achieve the best results.

[0031] The direct-injection gasoline engine combustion system and control method described in the present invention can stabilize combustion, accelerate combustion, and can effectively reduce the generation of particulate matter, and can reduce fuel consumption and emissions at the same time, and realize technical upgrading of exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com