Tunneling construction method for penetrating operating tunnel under shield in water-rich silt stratum

A construction method and shield technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of small injection volume, ineffective water stop, and inability to meet the requirements of strength, so that the injection volume is full and sufficient to ensure Construction safety, ensure the effect of earth pressure balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

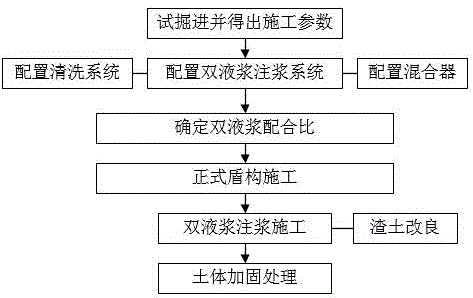

[0051] Such as figure 1 As shown, the excavation construction method for the shield to pass through the operational tunnel in the water-rich powder soil stratum includes the following steps:

[0052] a. Use the shield machine to test the excavation in the test section, and obtain the construction parameters;

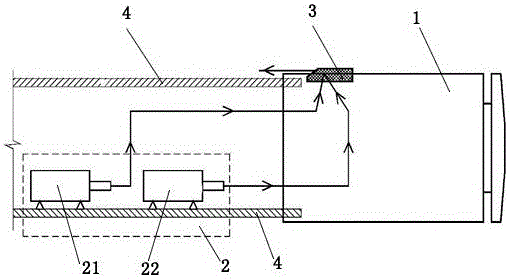

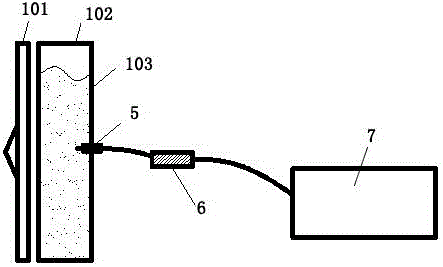

[0053] b. Configure a double-fluid grouting system, a cleaning system and a mixer on the shield machine, and the mixer is used to mix the double-fluid slurry delivered by the dual-fluid grouting system, and the dual-fluid grouting system includes Two kinds of grout stored separately, and a grouting system that can solidify quickly after the two kinds of grout are mixed;

[0054] c. Determine the mixing ratio of the double liquid slurry;

[0055] d. Carry out formal shield construction according to the construction parameters obtained in step a;

[0056] e. Use the process of adding water or foam to improve the dregs and carry out double-liquid grouting construction si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com