Coupling fracturing method for hard coal bed roof

A coal seam roof and hard roof technology, which is applied in the direction of earthwork drilling, discharge machinery, etc., can solve the problems of reduced degree of fracture, waste of drilling holes, easy closure, etc., and achieve the goal of improving fragmentation, safe and reliable construction, and weakening the strength of rock formations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0023] The hard coal seam roof coupling fracturing method of the present invention, concrete steps are as follows:

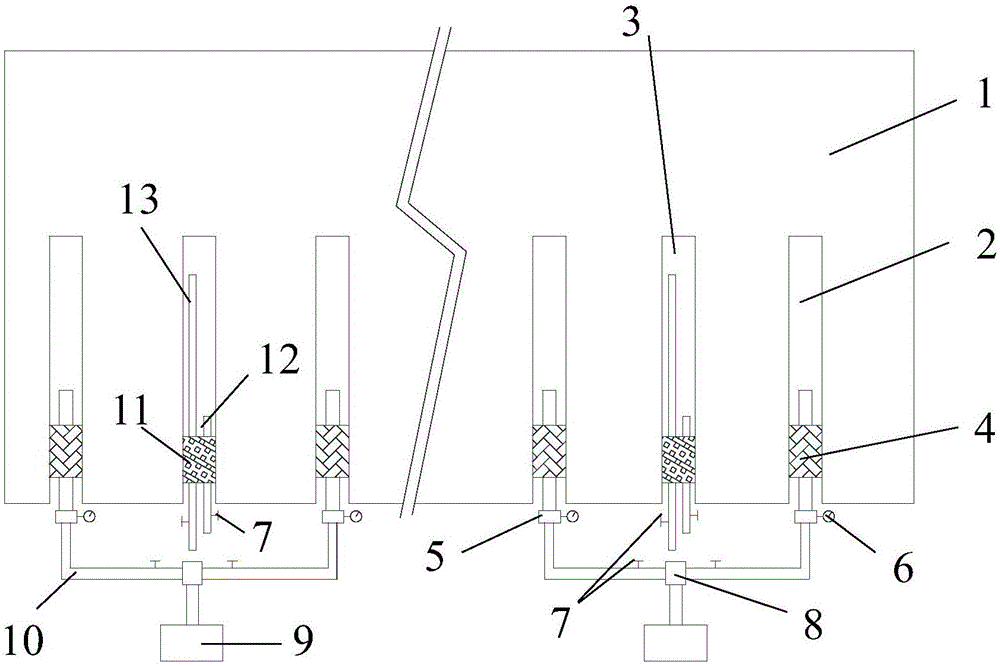

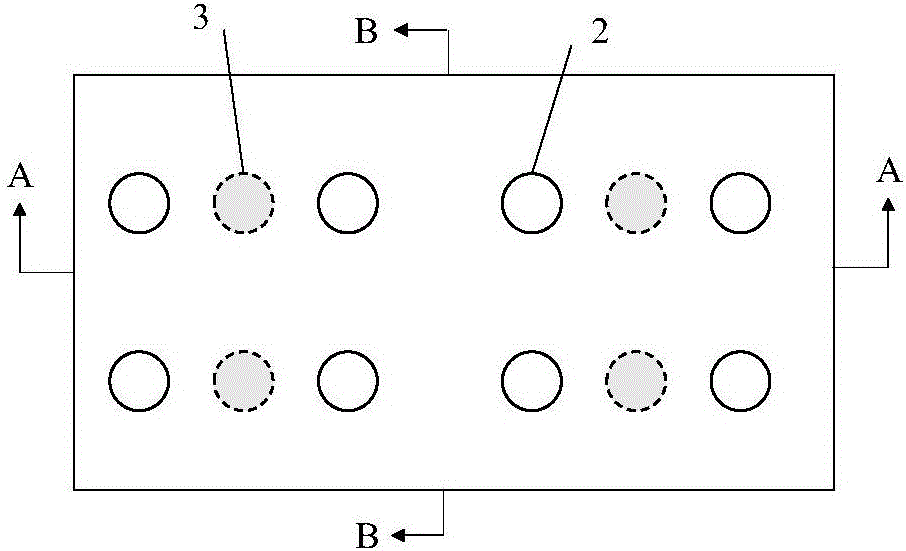

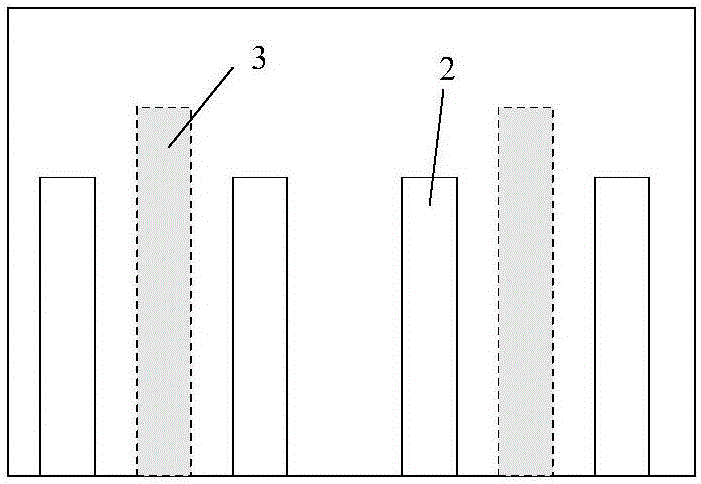

[0024] a. Drilling: First, use a drilling rig to drill multiple holes into the hard roof 1 to the design depth. The multiple holes include the static fracturing hole 3 and the pulsating hydraulic fracturing hole 2. Both sides of the static fracturing hole 3 The boreholes used are pulsating hydraulic fracturing holes 2, and every two pulsating hydraulic fracturing holes 2 and one static fracturing hole 3 are combined into a fracturing system, and the spacing between the holes in the fracturing system is 4.5–5m. The depth of the fracturing borehole 2 is 10-13m, and the depth of the static fracturing borehole 3 is 12-15m. The direction of the static fracturing borehole 3 is the direction normal to the roof, and the included angles between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com