A composite perforating impulse automatic adjusting device

A technology of automatic adjustment and compound perforation, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc. It can solve the damage of casing, perforation string and tubing in the perforated well section and affect the perforation effect. , the duration of high pressure cannot be controlled, etc., to achieve the effect of increasing time accumulation and improving flow efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

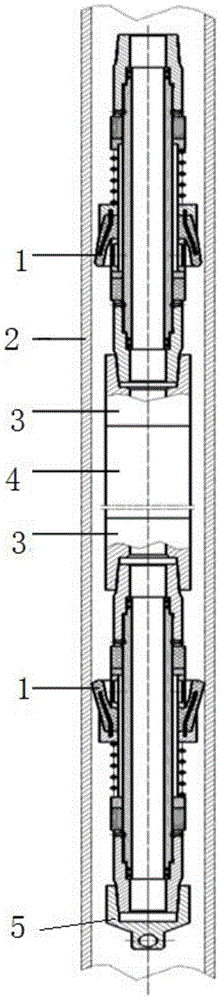

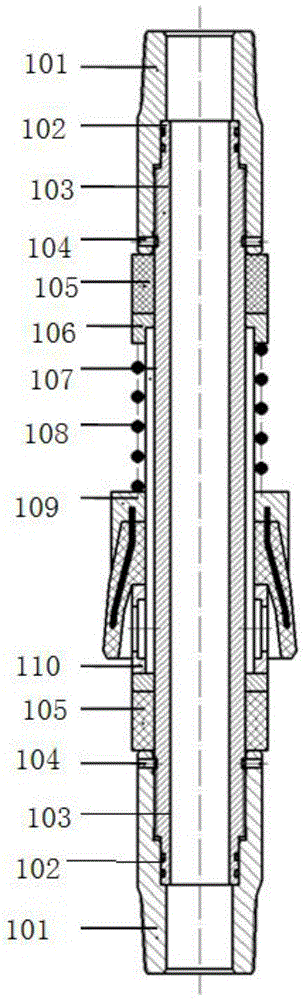

[0020] Such as Figure 1-2 As shown, the present invention is specifically described. The present invention provides a compound perforation impulse automatic adjustment device, the adjustment device includes a tubular structure casing 2, and the casing 2 is provided with a perforating gun barrel 4, The ports at both ends of the perforating gun string 4 are respectively connected to one end of the conversion joint 3 at opposite positions, and the other end of the conversion joint 3 is connected to a regulator 1, and any one of the regulators 1 One port position of 1 is provided with plug 5. The adjuster 1 includes a central tube 103 with a cylindrical structure, and the two ends of the central tube 103 are respectively sleeved with a joint 101 and a shock absorber 105 with a cylindrical structure in order from outside to inside, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com