Multichannel end portion full-circumferential-direction elastic support and isolation sealing device

A technology of elastic support and sealing device, which is used in cable inlet sealing device, sealing/packing, wellbore/well components, etc., can solve the problem that the packer does not meet the functional requirements of special processes, and improve the unsealing performance. , The effect of improving the sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

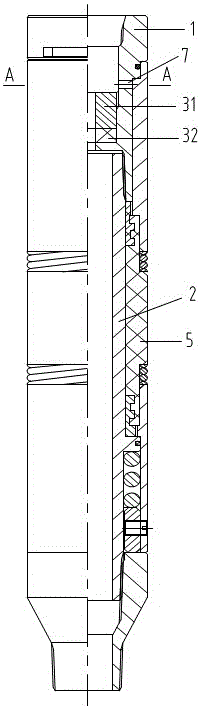

[0018] In this specification, the top edge of a page is referred to as top and the bottom edge of a page is referred to as bottom according to the illustrations.

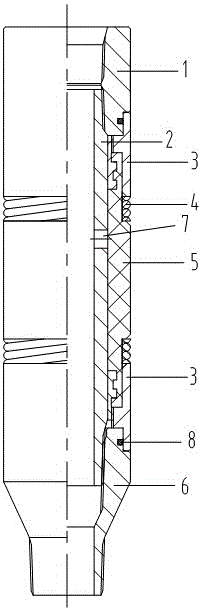

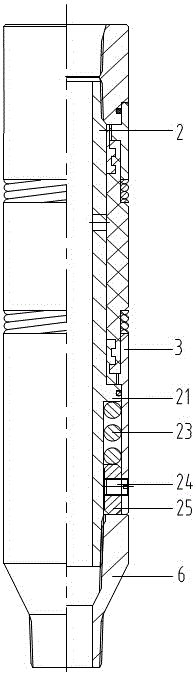

[0019] See figure 1 and Figure 7 As shown, the multi-channel end elastically supports the isolation and sealing device in the full circumferential direction. The two ends of the central tube 2 are respectively threaded to connect the upper joint 1 and the lower joint 6. The expansion rubber sleeve 5 is set outside the central tube 2. The two ends are covered with a sheath 3 and threaded. The sheath 3 is also socketed with the upper joint 1 and the lower joint 6. The setting hole 7 communicates with the annular space between the central tube 2 and the expansion rubber cylinder 5. One or both ends of the type rubber tube 5 are sleeved with a protection spring 4, and the protection spring 4 is located below the upper sheath 3 or above the lower sheath 3.

[0020] In the structure of the present invention, sealing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com