Water seal ring of mechanical seal gland

A technology of mechanical sealing device and water sealing ring, applied in mechanical equipment, machine/engine, liquid fuel engine, etc., can solve problems such as unsatisfactory sealing effect and leakage of quenching liquid, achieve reasonable structure, improve sealing ability, installation and use handy effect

Inactive Publication Date: 2014-02-26

DANDONG COLOSSUS GROUP

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because there is a gap between the water seal ring and the shaft sleeve, the quenching liquid can easily leak out of the pump through the gap, and the sealing effect is not ideal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

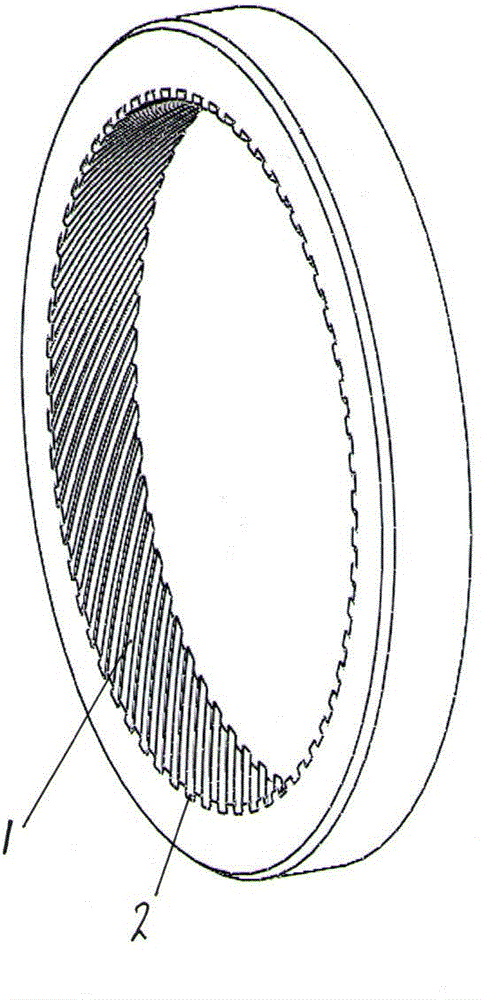

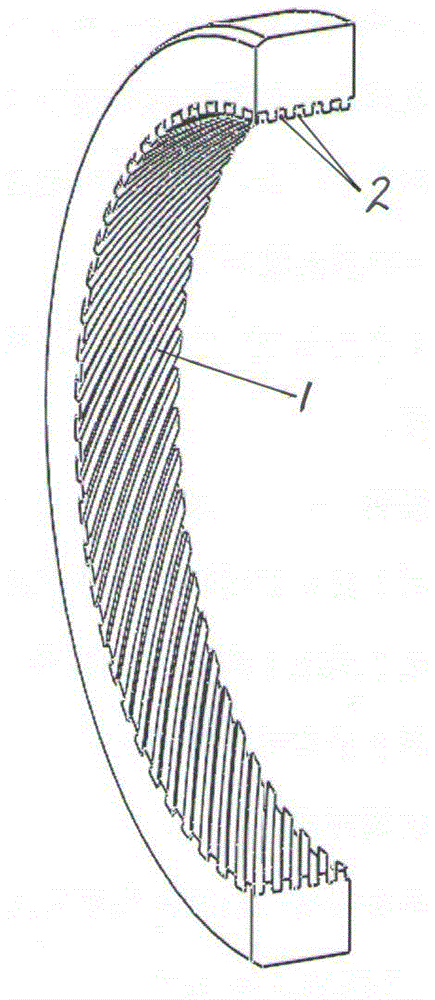

[0011] The water seal ring of the gland of the mechanical seal device of the present invention is provided with a spiral groove 2 on the inner ring surface 1 of the water seal ring to form a spiral pumping ring.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A water seal ring of a mechanical seal gland is characterized in that spiral grooves are formed in the inner annular face of a water seal ring, and a spiral pump ring is formed. The water seal ring is reasonable in structure, good in sealing effect and convenient to mount and use, and additional space is omitted.

Description

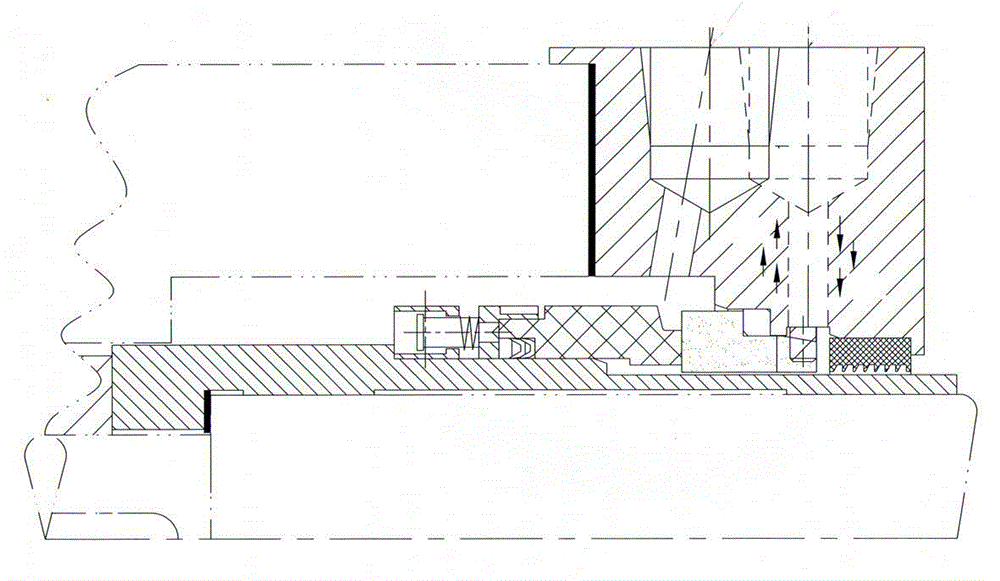

technical field [0001] The invention relates to a water seal on a mechanical seal gland. To improve the sealing effect of the water seal on the gland. Background technique [0002] There is a water seal on the gland of the mechanical seal device, especially in the API682-62 scheme, the water seal is a very commonly used auxiliary sealing element. The water seal on the gland of the traditional mechanical seal device is to set up a labyrinth groove or throttle groove on the inner ring surface of the water seal ring to reduce the leakage of quenching water. When the pump shaft is running, a labyrinth groove and shaft Or the shaft sleeve cooperates, the shaft sleeve rotates to drive the quench liquid to rotate to generate centrifugal force, and cooperates with the resistance of the throttle ring groove to the liquid to prevent the quench liquid from leaking outward. Because there is a gap between the water seal ring and the shaft sleeve, the quench liquid can easily leak out...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04D29/12

Inventor 关键于平超刘铁峰何德贵王慧许斌马宇滕朋唐志坚

Owner DANDONG COLOSSUS GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com