Wind-resistant reinforcing method for 10 kV beeline pole and windstay wire device

A wire-pulling device and straight-line rod technology are applied in the field of windproof reinforcement of electric pole lines, which can solve the problems of insufficient anti-overturning bending moment, large strength ratio, and large floor space, so as to improve the comprehensive utilization and increase the utilization ratio. , the effect of improving wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

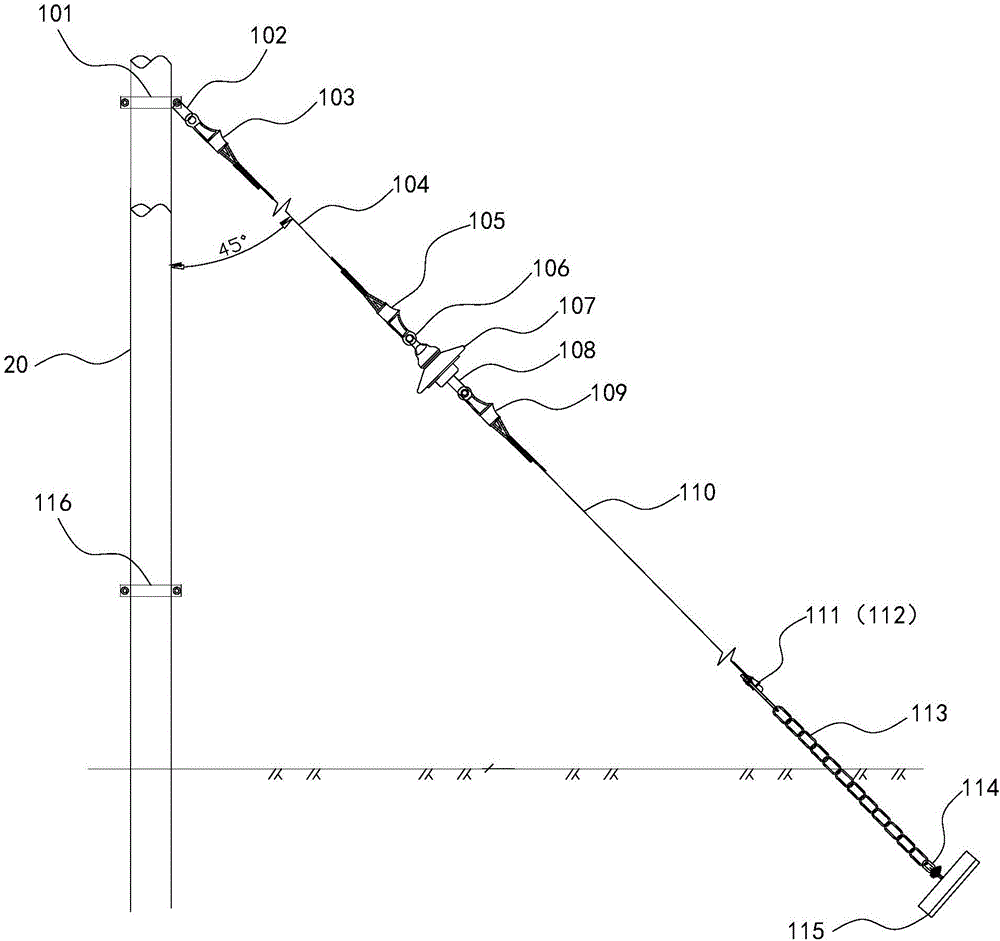

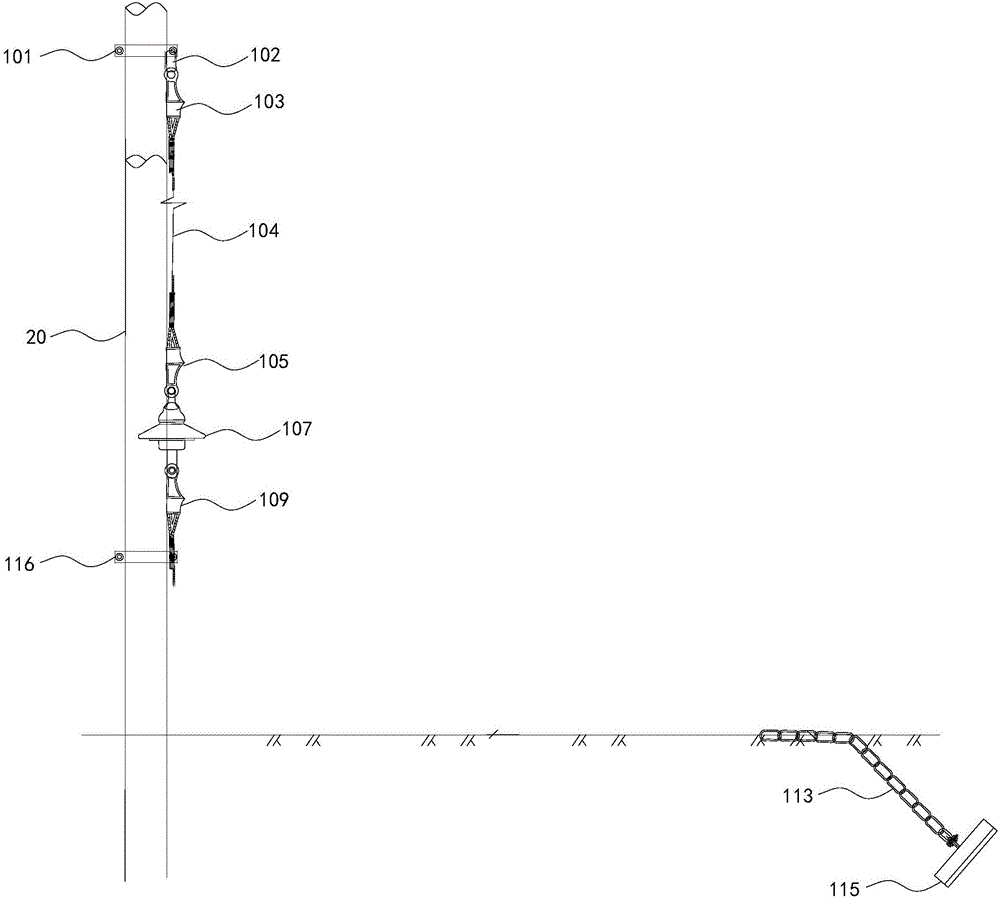

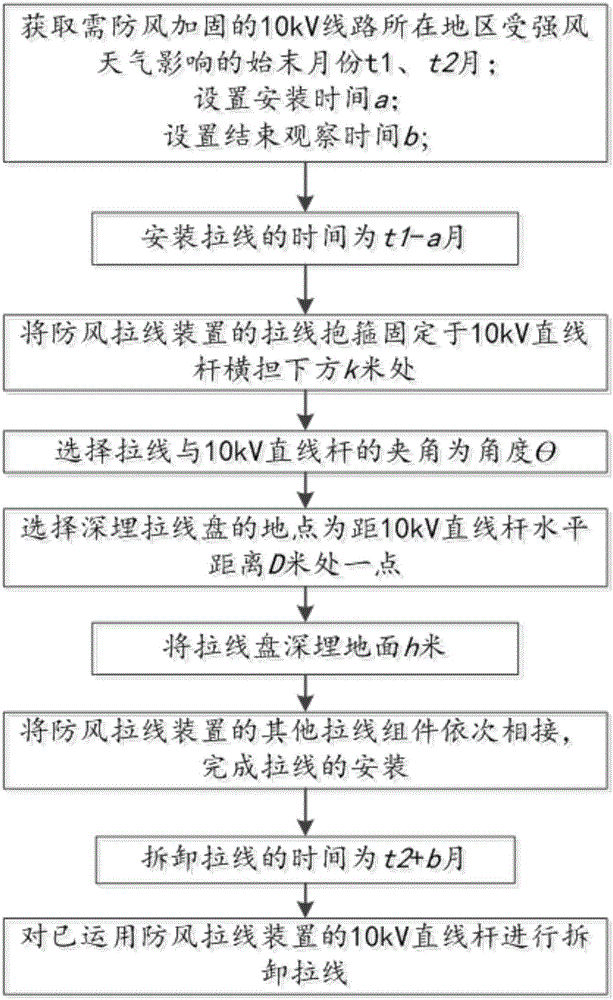

[0033] like figure 1 As shown, a windproof cable device for 10kV linear rod windproof reinforcement of the present invention includes cable hoop 101, extension ring 102, first wedge-shaped clamp 103, first cable 104, and second wedge cable connected in sequence. Clip 105, ball hanging ring 106, insulator 107, bowl hanging plate 108, third wedge wire clip 109, second guy wire 110, UT wire clip 111, defense cap 112, wire chain 113, U-shaped ring 114 and wire reel 115, the part of the pull chain 113 is exposed to the ground, and the pull wire reel 115 is buried underground; the part of the pull chain 113 exposed to the ground refers to the x meters of the pull chain 113 exposed to the ground for connecting other parts of the pull wire device; the x meter refers to What is the physical length of the portion of the pull chain 113 exposed to the ground, usually 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com