Manufacturing method of carbon fiber cloth pre-constrained ultra-high performance concrete column

A carbon fiber cloth, ultra-high performance technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of pre-constrained RPC columns, not fully utilized, and insufficient strength of carbon fiber cloth, and the principle is clear and clear. , the effect of increased strength and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

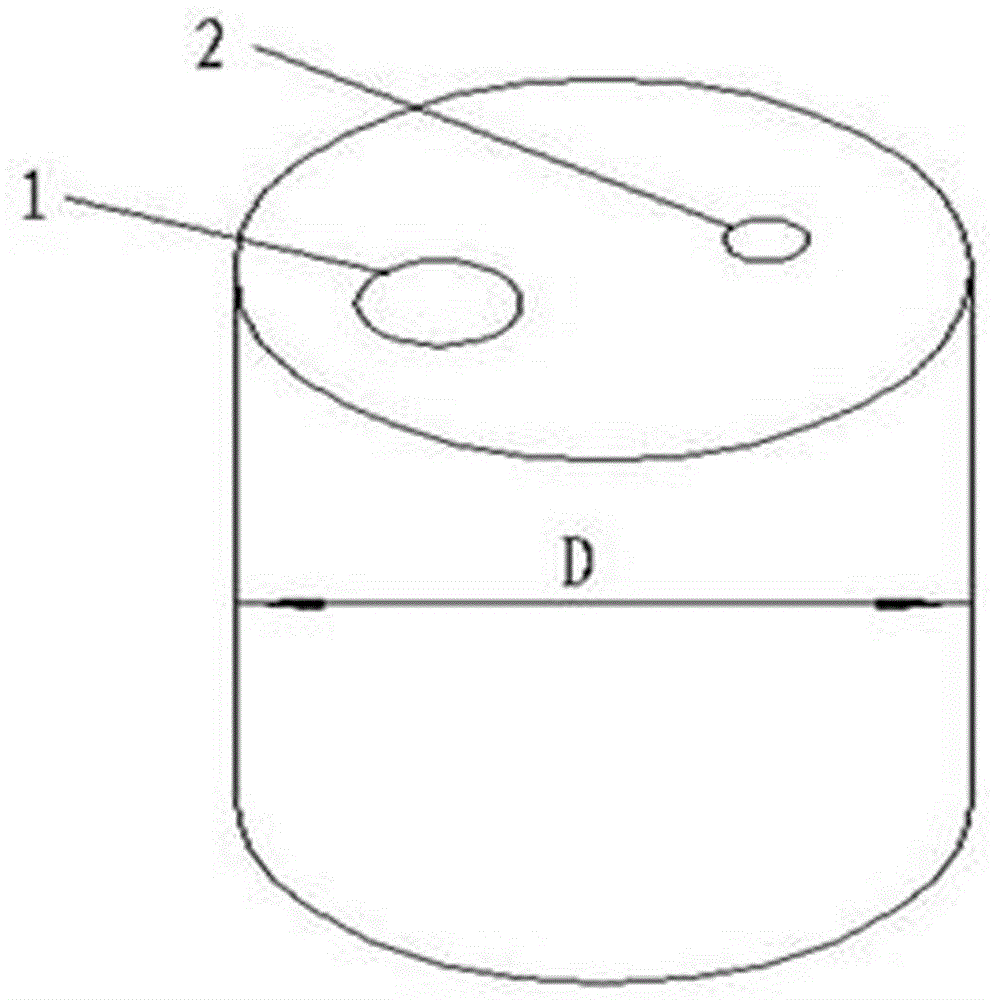

[0030] see figure 1 , is one of the specific embodiments of the manufacturing method of the carbon fiber cloth pre-confined ultra-high performance concrete column provided by the present invention, figure 2 Shown is the cross-sectional force schematic diagram of the active powder concrete RPC column that adopts the present invention to make, and makes the closed cylinder tube with carbon fiber cloth, and offers packing hole 1 and air-filling hole 2 on one of the circular faces, and the The circular face acts as the top face;

[0031] Seal the filling hole 1 and fill the closed cylinder with compressed air through the inflation hole 2 to form an upright and full hollow cylinder;

[0032] Fill the active powder concrete RPC layer by layer through the filler hole 1 until the cylinder is filled, and vibrate and compact to form an active powder concrete RPC column;

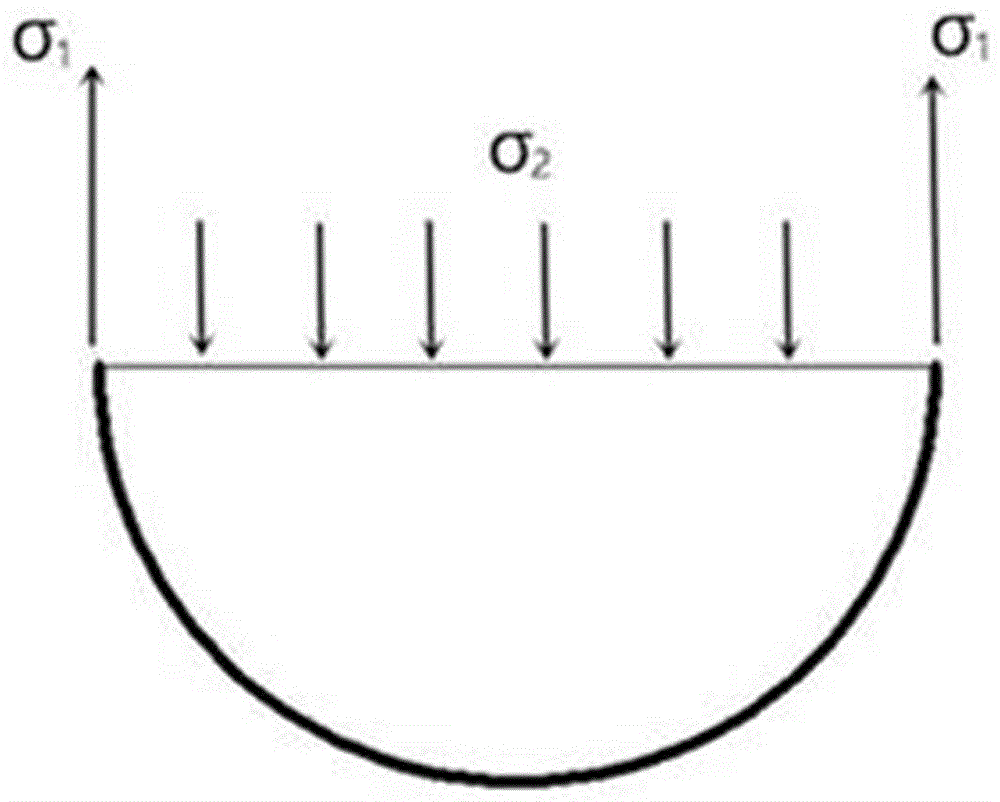

[0033] Apply a certain pressure on the upper and lower bottom surfaces of the active powder concrete RPC column; ...

Embodiment 2

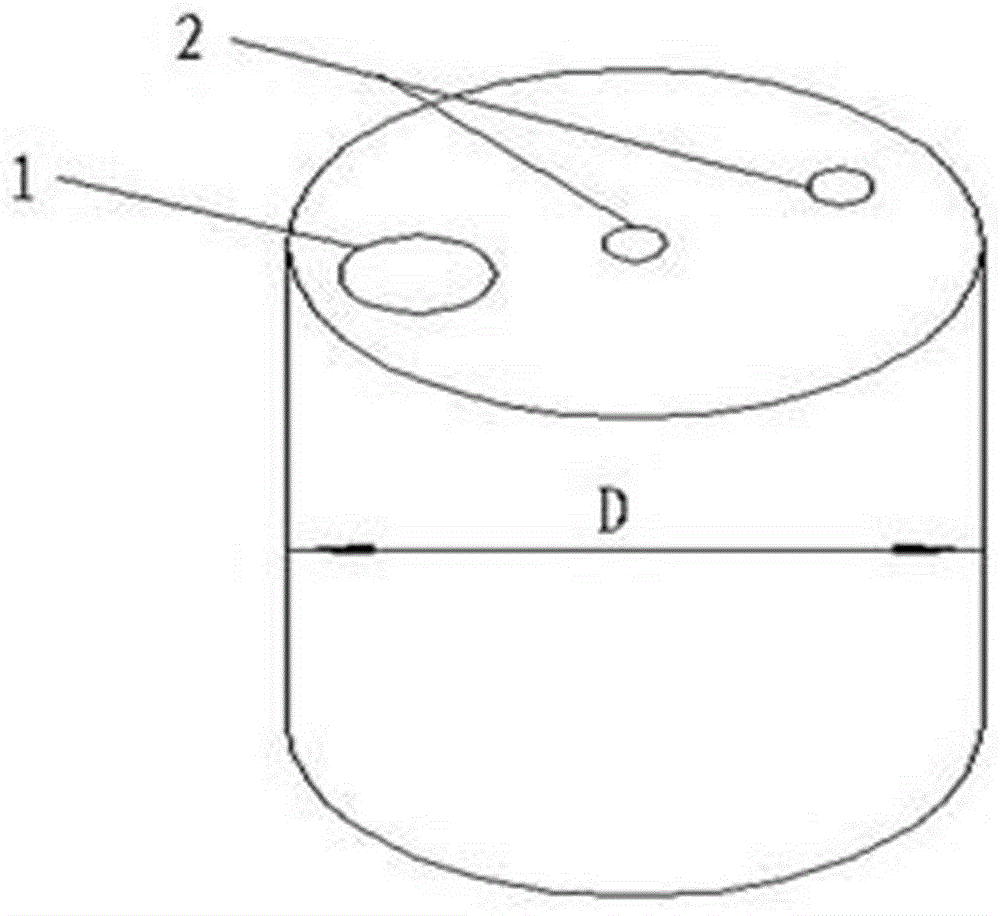

[0046] see image 3 and Figure 4 , the specific implementation of the manufacturing method of the fiber cloth pre-constrained ultra-high performance concrete column provided by the embodiment of the present invention, the difference from Example 1 is that the formed active powder concrete RPC column is hollow, such as Figure 4 As shown, the middle is a hollow column. The specific method is to make a closed cylindrical structure with carbon fiber cloth, which is a closed cylindrical structure with two inner and outer layers. The sealing packing hole 1 is opened on the annular surface formed by the inner and outer layers. There are two, one is set on the torus, and the other is set on the inner circular surface on the same surface as the torus. After filling with compressed air, an inner cylinder and an outer torus are formed. The cylinder is coaxial, and the active powder concrete RPC filled from the filler hole enters the annular cylinder, and is filled and compacted to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com