Pre-assembled steel column base anchor bolt structure

A pre-assembly and anchoring technology, applied in building construction, building material processing, construction, etc., can solve problems such as low efficiency and slow speed, and achieve the effect of strong structure, improvement of project quality and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

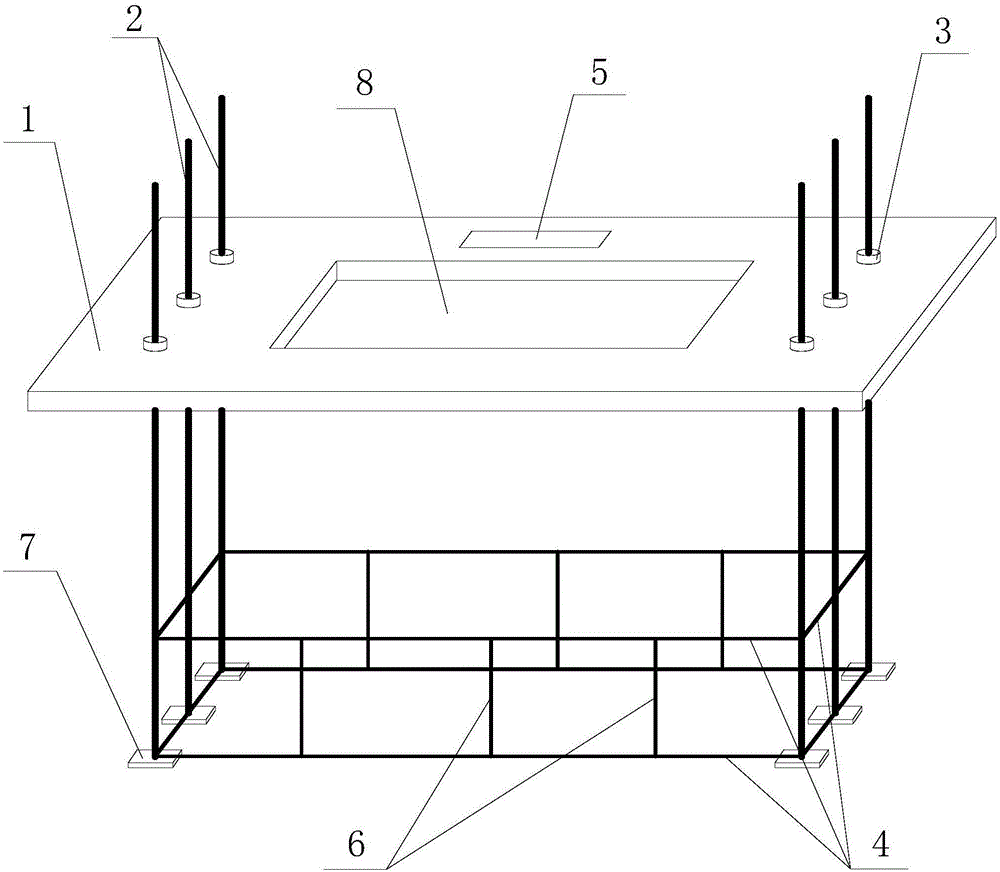

[0027] Such as figure 1 A pre-assembled steel column foot anchor bolt structure shown includes a positioning template 1, anchor bolt holes are set on the positioning template 1, anchor bolts 2 are inserted into the anchor bolt holes, and the positioning template 1 is fixed to the anchor bolt 2 by nuts 3, The axes of each anchor bolt 2 are all parallel, and the transverse ribs 4 are fixedly connected between two adjacent anchor bolts 2, and the transverse ribs 4 are located on the lower side of the positioning template 1, and the transverse ribs 4 are perpendicular to the axis of the anchor bolts 2; A level 5 is provided on the upper surface of the positioning template 1 . There are two transverse ribs 4 arranged between two adjacent anchor bolts 2 , one of which is located at the bottom of the anchor bolts 2 . The two transverse ribs 4 are distributed along the axial direction of the anchor bolt 2 . A plurality of longitudinal ribs 6 are fixedly connected between two adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com