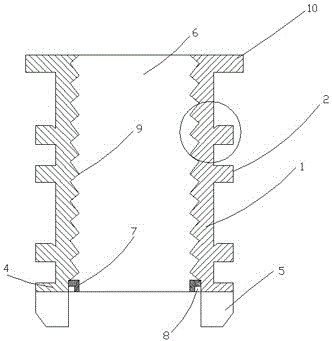

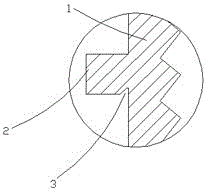

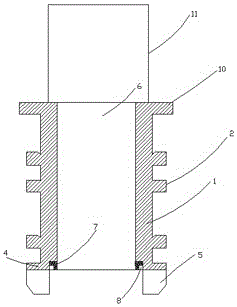

Water pipe connector insert and alloy material used for producing water pipe connector insert

A technology of water pipe joints and alloy materials, applied in the direction of pipes/pipe joints/pipes, pipe connection layout, mechanical equipment, etc., can solve the problems of poor overall material performance, easy cracking, etc., to increase flexibility, prolong service life, and solve problems Effects of leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: The present invention relates to an alloy material for producing water pipe joint inserts, which is characterized in that: according to weight percentage, it includes the following components: copper component: 50-60%; lead component: 1-2.5% %; aluminum component: 0.3-1%; iron component: 0.3-0.8%; cadmium component: 0.001-0.01%; zinc component: the balance.

[0041] Example 1:

[0042] An alloy material for the production of water pipe joint inserts, including the following components according to weight percentage: copper component: 50%; lead component: 2.5%; aluminum component: 0.3%; iron component: 0.3% ; Cadmium component: 0.001%; Zinc component: balance.

Embodiment 2

[0044] An alloy material for the production of water pipe joint inserts, including the following components according to weight percentage: copper component: 55%; lead component: 1%; aluminum component: 0.5%; iron component: 0.5% ; Cadmium component: 0.003%; Zinc component: balance.

Embodiment 3

[0046] An alloy material for the production of water pipe joint inserts, including the following components according to weight percentage: copper component: 57%; lead component: 1.5%; aluminum component: 0.6%; iron component: 0.5% ; Cadmium component: 0.005%; Zinc component: balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com