A kind of preparation method of high-structure complete high-dispersion graphene/metal composite material

A composite material and graphene technology, applied in graphene, metal processing equipment, transportation and packaging, etc., can solve the problems of many structural defects, unfavorable mechanical properties, insufficient graphene reduction, etc., to achieve small damage, excellent characteristics, Effects that are cheap to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Aluminum powder-coated cationic surfactant: Add flaky aluminum powder with a thickness of about 500nm into 1wt.% cetyltrimethylammonium chloride alcohol solution, stir for about 1 hour, filter and rinse to obtain cationic surfactant Flake aluminum powder coated with surfactant.

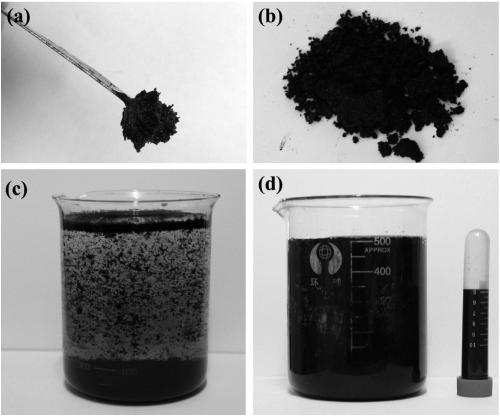

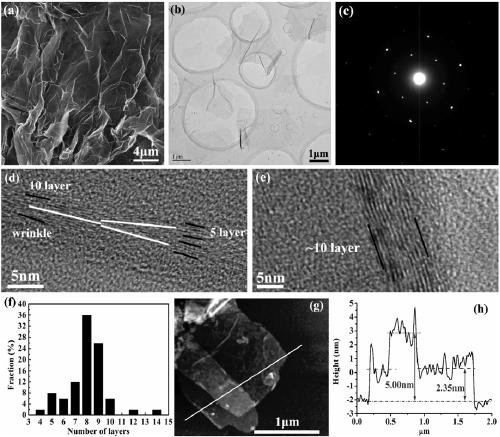

[0037] Preparation of graphene dispersion: configure a mixed aqueous solution containing 2wt.% sodium dodecylbenzenesulfonate and 2wt.% ammonium sulfate as the electrolyte; connect the graphite paper to the anode of the power supply, connect the copper wire to the cathode of the power supply, and connect the cathode to the anode With a distance of 4 cm, the electrochemical stripping was performed in the above electrolyte at a loading voltage of 10 V. After the peeled product is filtered, rinsed, ultrasonically dispersed and centrifuged to obtain a uniformly dispersed graphene aqueous solution, the corresponding anode material, peeled product and graphene dispersion are as follows: figure 1 As ...

Embodiment 2

[0043] Copper powder-coated cationic surfactant: Add flaky copper powder with a thickness of about 800nm into 1wt.% cetyltrimethylammonium chloride alcohol solution, stir for about 1 hour, filter and rinse to obtain cationic surfactant Activator coated flake copper powder.

[0044] Preparation of graphene dispersion: configure a mixed aqueous solution containing 3wt.% sodium dodecylbenzenesulfonate and 2wt.% ammonium sulfate as the electrolyte; connect the graphite rod to the anode of the power supply, connect the copper wire to the cathode of the power supply, and connect the cathode to the anode With a distance of 2 cm, the electrochemical stripping was performed in the above electrolyte at a loading voltage of 8 V. The stripped product is filtered, rinsed, ultrasonically dispersed and centrifuged to obtain a uniformly dispersed graphene aqueous solution.

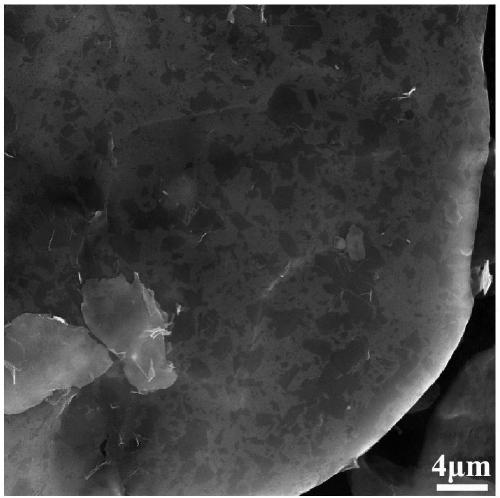

[0045] Composite material powder preparation: add 300g flake copper powder to 800ml graphene aqueous solution with a...

Embodiment 3

[0050] The preparation of the graphene dispersion is the same as in Example 2, except that after the flaky Cu powder has adsorbed the graphene, the coating of the cationic surfactant is repeated, and then 800ml of graphene with a concentration of 0.6mg / ml is added. The graphene is continuously adsorbed in the aqueous solution, and the obtained composite material powder is cold-pressed, hot-pressed and hot-extruded to obtain a dense 1vol.% graphene / copper composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com