High-speed steel circulating water bath annealing pipe

A circulating water bath and annealing tube technology, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of high cost and inconvenient sealing of tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

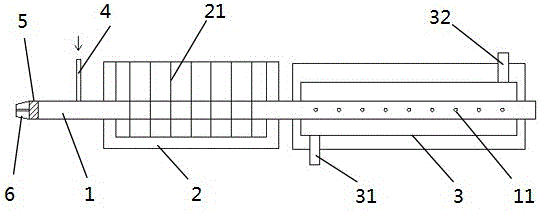

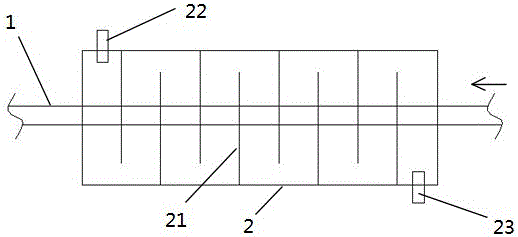

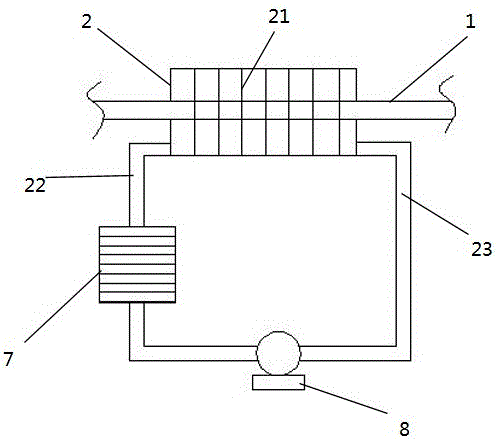

[0023] Embodiment 1: A high-speed steel circulating water-bath annealing pipe, the high-speed steel circulating water-bath annealing pipe includes an annealing pipe main body; the annealing pipe main body is sequentially provided with a combustion chamber and a water bath along the high-speed steel movement direction; the water bath The two ends along the direction of the main body of the annealing pipe are respectively provided with a water inlet pipe and a water outlet pipe; the water in the water bath overflows the main body of the annealing pipe; the water inlet pipe and the water outlet pipe are connected by a circulation pump; the main body of the annealing pipe is provided with A plurality of gas holes are arranged on both sides of the pipe section in the horizontal direction; an igniter is arranged in the combustion chamber; a fresh air inlet is provided on the lower end surface of the combustion chamber; Smoke outlet; the high-speed steel outlet end of the main body of...

Embodiment 2

[0025] Embodiment 2: A high-speed steel circulating water-bath annealing pipe, the high-speed steel circulating water-bath annealing pipe includes an annealing pipe main body; the annealing pipe main body is provided with a combustion chamber and a water bath in sequence along the high-speed steel movement direction; the water bath The two ends along the direction of the main body of the annealing pipe are respectively provided with a water inlet pipe and a water outlet pipe; the water in the water bath overflows the main body of the annealing pipe; the water inlet pipe and the water outlet pipe are connected by a circulation pump; the main body of the annealing pipe is provided with A plurality of gas holes are arranged on both sides of the pipe section in the horizontal direction; an igniter is arranged in the combustion chamber; a fresh air inlet is provided on the lower end surface of the combustion chamber; Smoke outlet; the high-speed steel outlet end of the main body of ...

Embodiment 3

[0027]Embodiment 3: A high-speed steel circulating water-bath annealing pipe, the high-speed steel circulating water-bath annealing pipe includes an annealing pipe main body; the annealing pipe main body is provided with a combustion chamber and a water bath in sequence along the high-speed steel movement direction; the water bath The two ends along the direction of the main body of the annealing pipe are respectively provided with a water inlet pipe and a water outlet pipe; the water in the water bath overflows the main body of the annealing pipe; the water inlet pipe and the water outlet pipe are connected by a circulation pump; the main body of the annealing pipe is provided with A plurality of gas holes are arranged on both sides of the pipe section in the horizontal direction; an igniter is arranged in the combustion chamber; a fresh air inlet is provided on the lower end surface of the combustion chamber; Smoke outlet; the high-speed steel outlet end of the main body of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com