Smoke dust removing control system

A control system and smoke and dust technology, applied in the direction of manufacturing converters, etc., can solve the problems of energy waste, high production cost, high flue gas and dust content, and achieve the effect of avoiding the opening of the furnace fan and preventing a large amount of smoke and dust from being discharged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

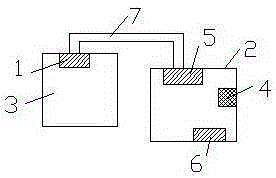

[0011] The present invention will be further described below with reference to the accompanying drawings.

[0012] A smoke and dust removal control system includes a collection device 1 and a control device 2, the collection device 1 and the control device 2 are connected to each other, the collection device 1 is arranged in a converter 3, and the control device 2 includes a control module 4 and a differential pressure gauge 5, and control the Module 4 is the PLC central processing unit, the differential pressure gauge 5 is connected to the PLC central processing unit, the PLC central processing unit is set with pre-stored values, and the differential pressure gauge transmits the value in the converter 3 to the PLC central processing unit, and the acquisition device 1 passes through. The conveying pipeline transmits the data to the differential pressure gauge 5, the value in the differential pressure gauge 5 is compared with the pre-stored value in the PLC central processing un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com