Separation process of camellia hull and seed and camellia hull and seed separator

A technology of camellia husk and camellia fruit, which is applied in the direction of solid separation, grading, fat production, etc., can solve the problems of not being suitable for large-scale production, poor sorting effect, and labor-intensive, etc., and achieve good seed husk separation effect and particle Uniform and high shelling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

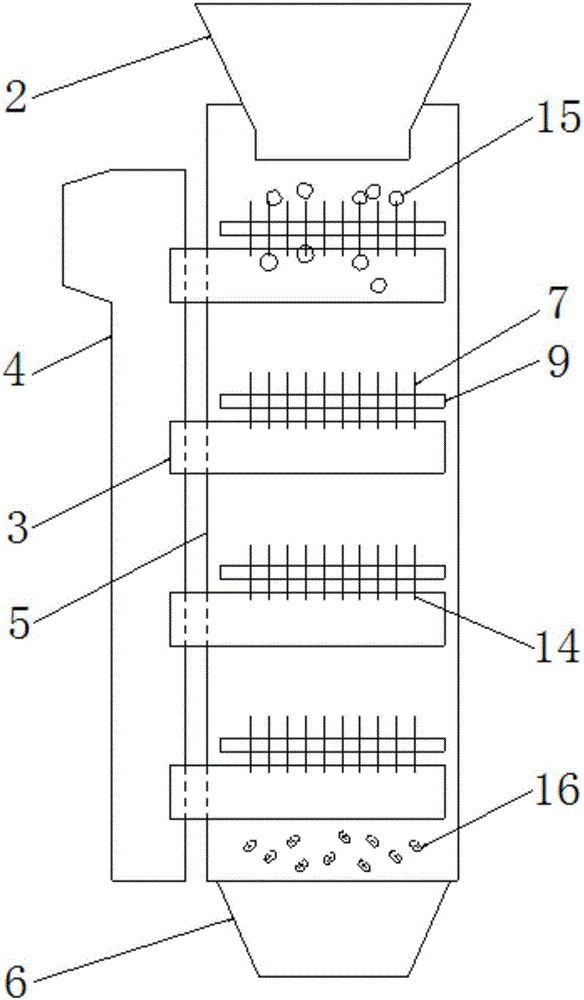

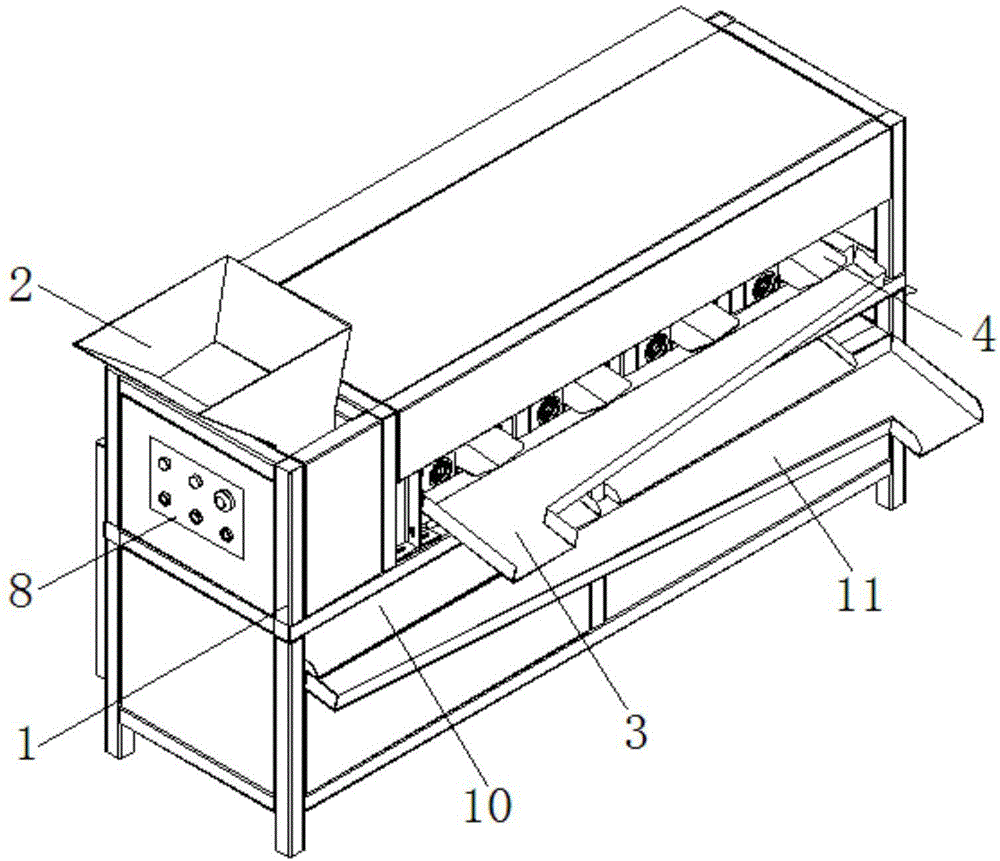

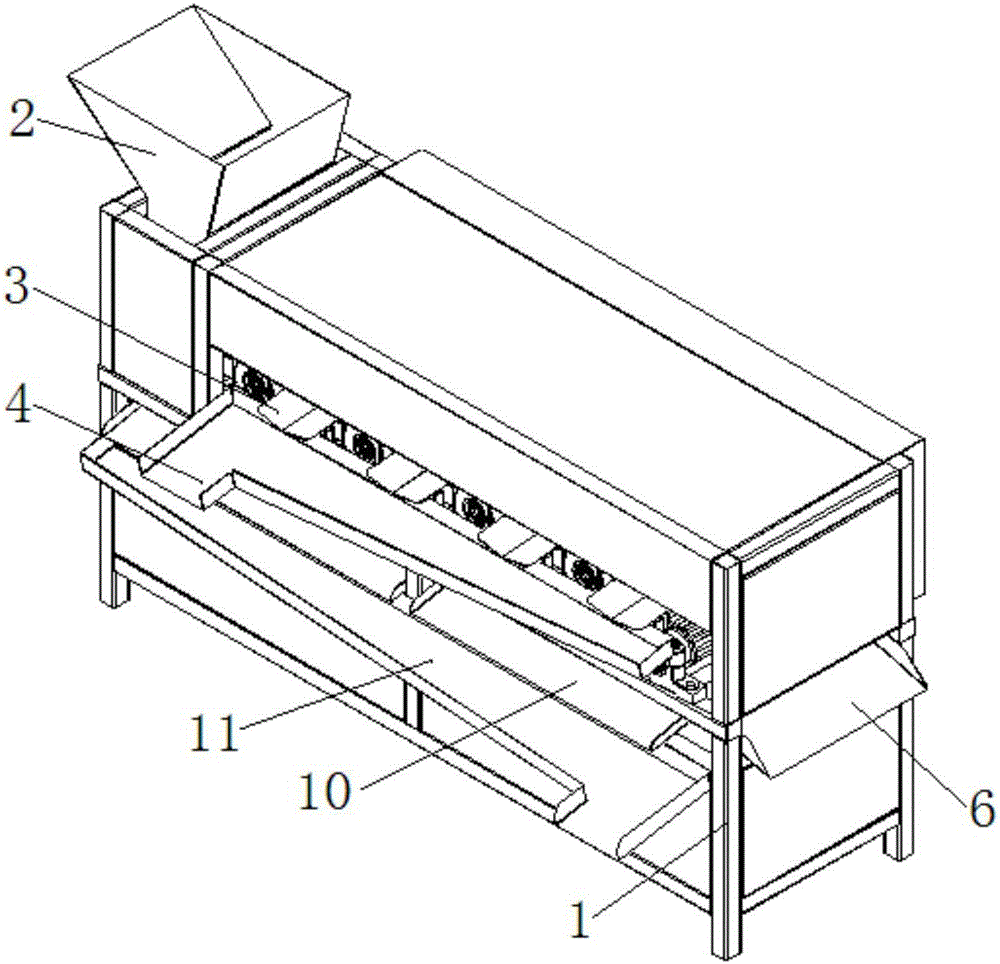

[0027] Taking the roller conveyor as an example for the conveying device, the camellia seed shell separation process provided by the invention, see figure 1 , specifically includes the following content: after the camellia fruit is peeled manually or by a sheller, a roller conveyor is used to transport the camellia mixed seed shell 15, and the roller gap of the roller conveyor is adjusted so that the gap is smaller than the minimum size of the camellia seed, During the conveying process of camellia mixed seed husks, small shells leak out through the roller gap of the roller conveyor, and the camellia husks in the camellia mixed seed husks are sorted by multi-level and misplaced sorting hook knives, that is, sorting The size of the hooks of the sorting hooks changes g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com