Graphene modified water-based conductive ink and preparation method thereof

A graphene modified, conductive ink technology, applied in inks, household appliances, applications, etc., can solve problems such as poor adhesion and weak conductivity, and achieve the effects of strong adhesion, reduced physical damage, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

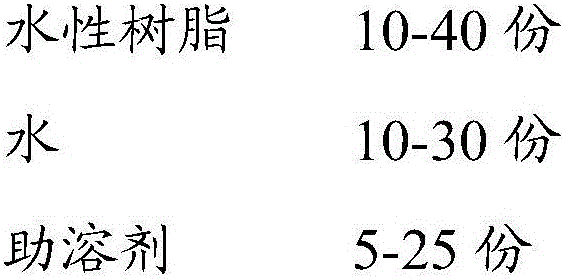

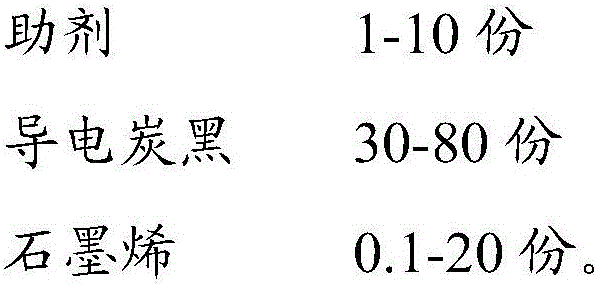

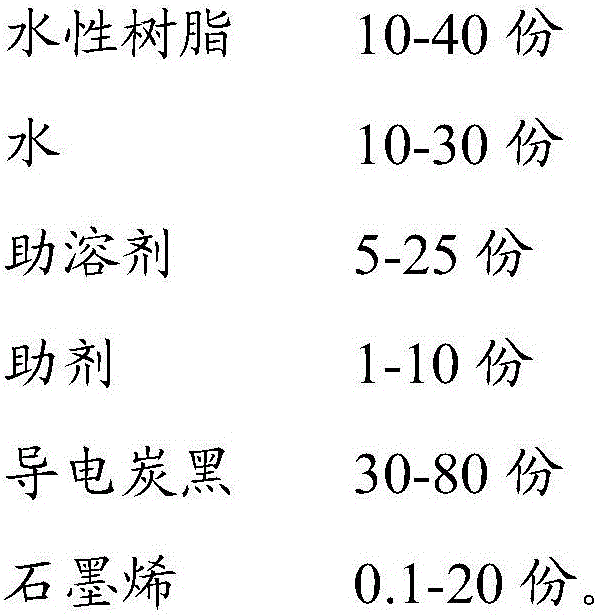

Method used

Image

Examples

Embodiment 1

[0027] Weigh 10 parts of water-based acrylate, 10 parts of water, 5 parts of ethanol, 5 parts of triethylamine, 1 part of polycarboxylate sodium salt, 1 part of fatty acid ester sulfate, and 1 part of hydrophobic polysiloxane defoamer 1 part, 1 part of organically modified polydimethylsiloxane, 1 part of associative acrylate, 30 parts of conductive acetylene carbon black, 0.1 part of multilayer graphene, put into the dispersion tank and stir and mix evenly to obtain pre-dispersed material; transfer the obtained pre-dispersed material to a sand mill until the material fineness reaches below 10 microns; filter the ground material to obtain graphene-modified water-based conductive ink.

Embodiment 2

[0029] Weigh 20 parts of water-based polyurethane, 20 parts of water, 15 parts of ethanol, 15 parts of ethylene glycol butyl ether, 1.5 parts of potassium polyacrylate, 1.5 parts of alkylphenol polyoxyethylene ether, 0.4 parts of silicone defoamer, organic 1.5 parts of modified polydimethylsiloxane, 1.5 parts of associative acrylate, 60 parts of acetylene carbon black, and 10 parts of multilayer graphene are put into a dispersion tank and stirred and mixed uniformly to obtain a predispersed material; The pre-dispersed material is transferred to a ball mill until the material fineness reaches below 10 microns; the ground material is filtered to obtain a graphene-modified water-based conductive ink.

Embodiment 3

[0031] Weigh 40 parts of water-based phenolic resin, 30 parts of water, 25 parts of isopropanol, 2 parts of polyacrylic acid sodium salt, 2 parts of fatty acid ester sulfate, 2 parts of hydrophobic polysiloxane defoamer, machine-modified 2 parts of polydimethylsiloxane, 2 parts of polyurethane rheological agent, put into the dispersing tank and stir, mix evenly to obtain a pre-dispersed material; transfer the obtained pre-dispersed material to a three-roll mill until the material fineness reaches Below 10 microns; filter the ground material to obtain graphene-modified water-based conductive ink.

[0032] According to the above-mentioned embodiment 1, embodiment 2 and embodiment 3, after the printed products made of graphene modified water-based conductive ink are cured, they are not easy to oxidize and stable in performance, resistant to acid and alkali and chemical solvent corrosion, and have good electrical conductivity Sex, the square resistance of conductive ink is less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com